Last Updated August 13, 2024

Entry-level ceramic coating sprays like Lifeproof have become a popular choice for car enthusiasts and everyday drivers looking to protect their vehicle’s paintwork. These coatings provide a layer of protection against environmental contaminants, UV damage, and minor scratches, enhancing the appearance and longevity of a car’s finish. However, there are significant differences between entry-level spray ceramic coatings and professional-grade ceramic coatings. This comparison will delve into these differences, examining aspects such as durability, application ease, performance, and cost.

Comparing Ceramic Coating Sprays to Professional Ceramic Coatings

1. Chemical Composition

Ceramic Coating Sprays: Entry-level spray consumer coatings are typically formulated with simpler chemistry and often contain a lower concentration of silica or silicon dioxide (SiO2). SiO2 is a critical component in ceramic coatings that forms a protective layer over the paint. These consumer-grade products often use a blend of SiO2 with other materials to lower production costs and make the product easier for non-professionals to apply.

Professional-Grade Ceramic Coatings: Professional-grade coatings contain a higher percentage of SiO2 or other advanced compounds like titanium dioxide (TiO2). The higher concentration of these active ingredients leads to a more robust protective layer. These coatings are engineered for durability and resistance to extreme conditions, including high temperatures, heavy contamination, and aggressive cleaning methods.

2. Durability and Longevity

Ceramic Coating Sprays: The longevity of spray coatings is typically shorter, ranging from six months to two years. This is partly due to their thinner application and the lower concentration of protective elements. While these coatings offer decent protection, they may need to be reapplied more frequently to maintain their effectiveness.

Professional-Grade Ceramic Coatings: Professional coatings are designed to last significantly longer, often ranging from two to five years, and in some cases, even up to a decade. The advanced formulation creates a more durable bond with the paint, offering superior resistance to environmental factors such as UV rays, acid rain, and road salt. This long-term protection makes them ideal for high-end vehicles or those exposed to harsh conditions.

3. Application Process

Ceramic Coating Sprays: These coatings are designed for ease of use, catering to DIY enthusiasts. The application process usually involves cleaning the vehicle, applying the coating using a spray or wipe-on method, and then buffing it to a shine. These products often include user-friendly instructions and may come with additional tools or applicators to simplify the process. While the application is relatively straightforward, achieving a high-quality finish may still require careful attention to detail.

Professional-Grade Ceramic Coatings: The application of professional-grade coatings is more complex and typically requires specialized equipment and training. The process often involves several stages, including thorough paint correction, precise application using a specific technique, and curing under controlled conditions. Professional applicators may use advanced tools like infrared lamps to accelerate curing and ensure an even, high-quality finish. This meticulous process ensures optimal performance but requires expertise and time.

4. Performance and Protection

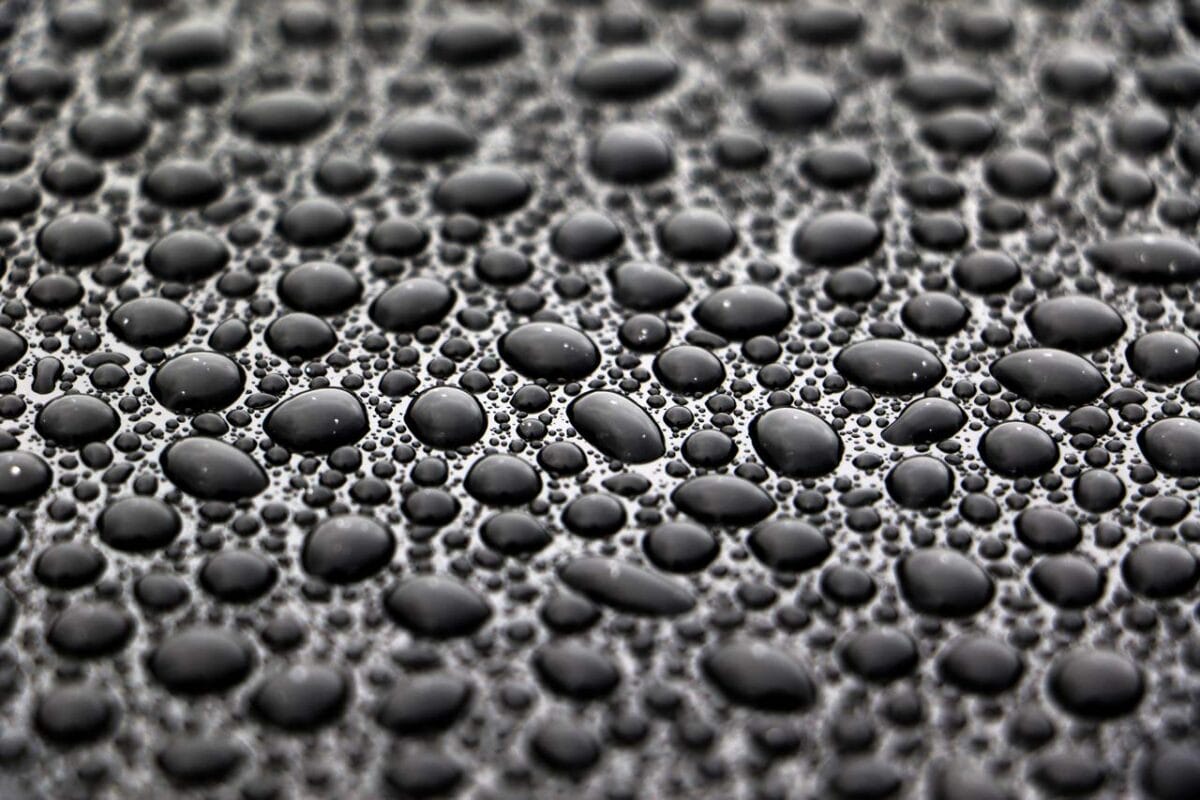

Ceramic Coating Sprays: While spray coatings offer a good level of protection, they may not provide the same level of performance as professional products. They generally offer resistance to water spotting, minor contaminants, and light scratches. However, their hydrophobic properties, which cause water to bead off, may not be as pronounced or long-lasting compared to professional-grade coatings.

Professional-Grade Ceramic Coatings: Professional coatings excel in performance, providing exceptional hydrophobic properties that cause water to bead off more effectively. They offer superior protection against chemical contaminants, UV damage, and physical wear. The coating’s enhanced hardness helps protect against swirl marks and minor scratches, maintaining the vehicle’s pristine appearance over time. This level of protection is particularly valuable for high-end vehicles or those subjected to extreme conditions.

5. Cost and Value

Ceramic Coating Sprays: The cost of entry-level coatings is relatively low, making them accessible to a broader audience. These products are priced to be affordable for the average car owner who wants to enhance their vehicle’s protection without significant investment. The value of entry-level coatings lies in their affordability and ease of application, offering a good balance between protection and cost for those who may not require long-term durability.

Professional-Grade Ceramic Coatings: Professional coatings come with a higher price tag, reflecting their advanced formulation and the expertise required for application. The cost includes not only the product itself but also the labor and expertise of professional detailers. While the initial investment is higher, the long-term value is significant due to the extended durability and superior protection. For car enthusiasts and owners of high-value vehicles, this investment often justifies the expense due to the prolonged benefits and the quality of the finish.

6. Maintenance and Upkeep

Ceramic Coating Sprays: Maintenance for consumer-grade coatings typically involves regular washing and occasional reapplication to maintain optimal protection. These coatings may require more frequent upkeep to ensure they continue to perform well and protect the vehicle effectively.

Professional-Grade Ceramic Coatings: Maintenance for professional coatings is generally minimal, thanks to their superior durability. Regular washing and proper care are usually sufficient to keep the coating in good condition. In many cases, professional-grade coatings can enhance the ease of maintenance, as their hydrophobic properties help repel dirt and water, reducing the frequency of washes and simplifying the cleaning process.

Conclusion

In summary, entry-level consumer ceramic coating sprays and professional-grade ceramic coatings each offer distinct advantages and cater to different needs. Entry-level coatings are accessible, easy to apply, and provide a good level of protection for a lower cost, making them suitable for everyday car owners. In contrast, professional-grade coatings offer superior durability, performance, and long-term protection, albeit at a higher cost and with a more complex application process.

The choice between the two often comes down to the specific needs and preferences of the vehicle owner. For those looking for a cost-effective solution with reasonable protection, entry-level coatings are a practical choice. However, for those seeking the highest level of protection and are willing to invest in professional services, a professional-grade ceramic coating provides unparalleled performance and longevity.

Is this useful for any other surfaces – stainless steel appliances, shower doors, etc.?

Absolutely! Just be sure to test in an inconspicuous area first for compatibility.