The good news about polishing car paint in 2024 is there are a LOT of options when it comes to machine polishers for beginners starting out doing paint correction. The bad news? There are SO MANY options now when it comes to polishers and buffers that it can be VERY confusing.

As a teacher of paint polishing, I keep an eye on ALL the new machines hitting the market so I can get the best tools for my students. That gives me a good perspective on what the BEST polishers for beginners, so in this article I’ll be reviewing some of the most popular options in the “entry level” polisher category so YOU can make an educated decision as a consumer.

Table of contents

- How Much Do Polishers for Car Paint Cost?

- Are Corded Polishers Better Than Cordless?

- What Are the Different Types of Polishers?

- The Difference Between Free Spinning Random Orbital and Gear Driven Orbitals

- Gear-Driven Orbital Polishers

- Gear Driven vs. Forced Rotation Dual Action Polisher?

- Free Spinning Random Orbital Polishers

- The upside to a free spinning random orbital polisher

- The downside to a free spinning random orbital polisher

- Brain Drain

- What Does Brain Drain mean?

- The Walking Effect versus Smooth Sailing

- Best Polishers for Beginners (Under $200)

- Best Free Spinning Random Orbital Polishers for Beginners

- Recommended: Griot’s Garage G9 Random Orbital Polisher – $169.99

- Runner-Up: BAUER 5.7 Amp 6 in. Short-Throw Random Orbit DA Polisher/Sander – $64.99

- 2nd Runner Up: PORTER-CABLE 7424XP Car Polisher and Buffer, 6-Inch, Orbital, Variable Speed – $139.00

- Not Recommended: BAUER 7.5 Amp, 6 in. Long-Throw Random Orbit DA Polisher – $79.99

- Best Mini Free Spinning Random Polisher for Beginners

- Recommended: Griot’s Garage G8 Mini Random Orbital Polisher – $144.99

- Best Gear Driven Orbital Polishers for Beginners

- Recommended: HERCULES 8 Amp 6 in. Forced Rotation Dual-Action Polisher – $119.99

- Which Polisher is the Best Value?

How Much Do Polishers for Car Paint Cost?

The price for a car polisher ranges from under $100.00 up to $800.00 – that’s a very wide spectrum of pricing options. Car polishers for beginners, however, generally range between $65 and $170. That’s what we’ll be reviewing in this article.

Are There Any Good Polishers Under $65?

There may be a few polishers available at discount stores that cost under our low price point of $65.00 but from experience, at this price point, these tools don’t have the power to enable you to de-swirl an average size passenger car in a time-efficient manner. Time is money and when it comes to power tools, the old adage rings true – you get what you pay for.

Are Corded Polishers Better Than Cordless?

There are 2 types of power options available with modern polishers on the market today.

Corded tools – These are tools you’ll need to use with an electrical power outlet.

Cordless tools – These are battery operated tools and each year, more of this style of tool is being introduced to the marketplace.

While there are some inexpensive battery-operated, cordless polishers on the market today, the performance of the tool and the performance of the battery technology do not make these practical options. I get it, we all want a cordless tool that works great, but the price for working great is a tick higher than most beginners are willing to spend. For the scope of this article, we will be looking at traditional corded polishers.

I will be sharing a new article for cordless polishers that are worth their asking price in the near future, so subscribe to the Dr. Beasley’s Newsletter here,

Click here to subscribe to the Dr. Beasley’s Newsletter

What Are the Different Types of Polishers?

Polishers differ based on the action they perform. When it comes to automotive paint machine polishers, there are 4 different types of tool actions:

- Free spinning random orbital polisher – Easiest, safest and inexpensive option.

- Gear-driven orbital polisher – Requires more physical strength. High and low cost options.

- Gear-driven rotary polisher – The most powerful polisher for fast defect removal. Can also cause damage if not used correctly.

- Gear-driven axial motion drum polisher – Unique design, the size and action of the tool requires more time investment to master. Not a practical first choice polisher for any beginner.

For this article and video, we will be looking at tools from the first 2 groups: the free spinning random orbital polishers and the gear-driven orbital polishers.

The Difference Between Free Spinning Random Orbital and Gear Driven Orbitals

First, notice the description for the first type of tool listed above includes the word RANDOM while the description for the second type of tool omits the word RANDOM.

Let me start by explaining what a gear-driven orbital polisher is and how it works. This will make it easier to understand what a free spinning random orbital polisher is and how it works.

Gear-Driven Orbital Polishers

This type of polisher has two sets of gears inside the housing at the head of the polisher. There’s an outer gear ring and there’s an inner geared backing plate. When turned on, the electric motor turns the spindle, which is directly connected to the inner geared backing plate, which in turn meshes with the outer gear ring forcing the backing plate to both rotate and oscillate with zero slippage or stalling.

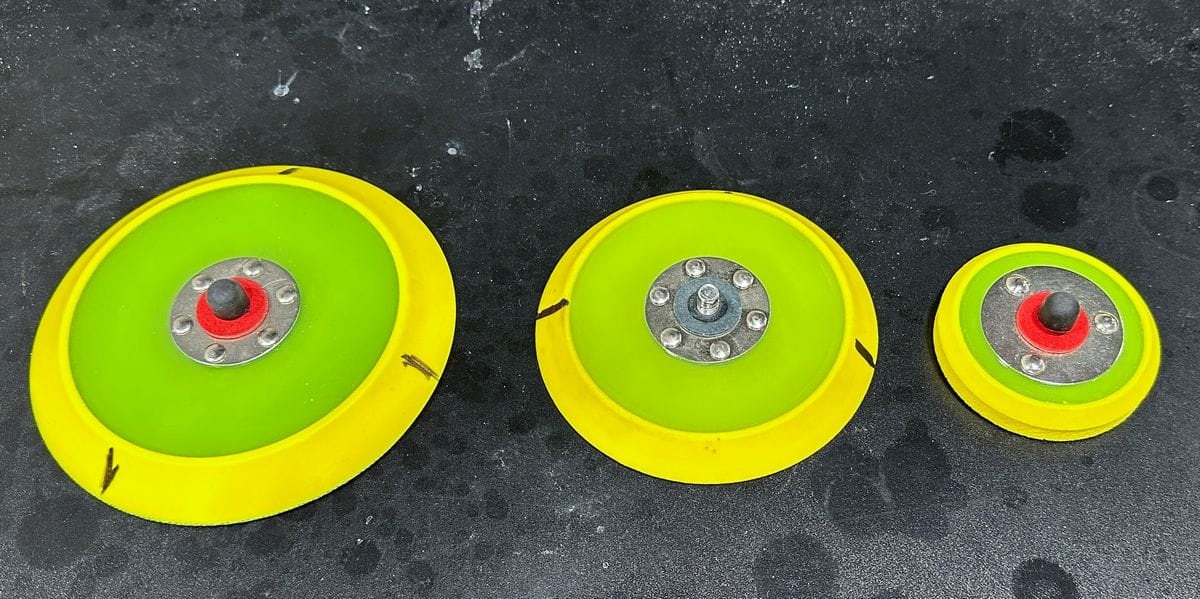

To see the gears so you can see the difference between a gear-driven orbital and a free spinning random orbital polisher, I’ll remove the backing plates from both the Harbor Freight Forced Rotation Dual Action Polisher and the Porter Cable 7424XP.

This is the Harbor Freight Forced Rotation Dual Action Polisher

The tool comes with the correct size hex head wrench to remove the bolt that holds the backing plate to the spindle.

IMPORTANT

Do not lose the bolt and the washers. The bolt is the correct length to ensure the gears correctly mesh together. If you must replace the bolt, be sure to get the exact size and thread bolt from a local hardware store. Too short of a bolt and you will not have enough threads in contact with the spindle to operate the tool safely. Too long of a bolt and there will be slop or slack between the gears and you can damage the gear sets.

The inner gear set

With the backing plate removed, you can see the inner gear set on the inside of the backing plate.

Outer gear set

In the below picture you can see the outer gear set that the inner gear set meshes with when the backing plate is attached to the spindle.

Because there is zero slippage or stalling, the backing plate and thus the buffing pad will both rotate and oscillate no matter what. This includes factors like,

- Tool speed

- Pad size diameter

- Pad size thickness

- Body panel shape – flat, concave or convex

- Body panel shape – large flat panels, thin long panels

- Dry pad versus wet pad

- Pad angle – whether the face of the pad is flat to the surface or on edge

None of the above factors or influences to the buffing operation will affect or hinder pad rotation and pad oscillation. All of the above factors WILL affect or hinder pad rotation and oscillation of free spinning random orbital polishers.

Gear Driven vs. Forced Rotation Dual Action Polisher?

I often see people refer to gear-driven orbital polishers and forced rotation polishers. My guess is these people are either misinformed or simply too lazy to type or say the full description for this type of tool. Harbor Freight got it right when they listed their version of the FLEX XC 3401 VRG aka The BEAST as a Forced Rotation Dual-Action Polisher. Adding the words Dual Action after Forced Rotation is technically correct as this tool offers two actions – rotation and oscillation.

When someone refers to the above type of tool using ONLY the words forced rotation, with or without knowing it, they are referring to a rotary polisher. Like the gear-driven orbital polisher, a rotary polisher is gear-driven. Thus a rotary polisher is forced rotation and forced rotation ONLY.

When you turn the power to the ON position on a rotary polisher, the electric motor forces the backing plate to spin in a single direction aka rotation. Thus a rotary polisher is a forced rotation polisher but a tool like the Harbor Freight Forced Rotation Dual Action Polisher is a forced rotation PLUS forced oscillation polisher. Subtle wording difference, but HUGE practical difference when using this type of tool.

Because there is no slippage between the inner and outer gear set, both the rotation and the oscillation are distinct and defined. In this case, the oscillation is 8mm. This means, the diameter of the oscillation or tiny circle is 8mm. It’s always constant, thus we don’t use the word RANDOM to describe the action of a gear-driven, orbital polisher.

To summarize, a gear-driven, orbital polisher is a forced rotation, forced oscillation polisher. There is zero pad stalling. Because there is zero pad stalling, there is zero wasted time and what I call “Brain Drain” — that is, focusing your attention on pad rotation instead of on the paint itself.

Free Spinning Random Orbital Polishers

Now that we’re all on the same page as to what a gear-driven orbital polisher is and how it works, let me explain what a free spinning random orbital polisher is and how it works.

With a free spinning random orbital polisher, instead of an inner and outer gear set, you have a free rotating spindle assembly connected to a counterweight.

Removing the backing plate on the Porter Cable 7424XP

Using the included Porter Cable Wrench, I slide the wrench into the spindle from the opposite side of the counterweight and then while holding the wrench, remove the backing plate via a counterclockwise motion.

With the backing plate removed, here’s what is called a free spinning or free rotating spindle assembly.

I can take my finger and easily spin the spindle freely. This same thing applies to any brand or orbit stroke of free spinning random orbital polisher. The spindles and counterweights on other brands of polishers may look different but they operate the same way.

Here’s the counterweight

When the tool is brought up to a high speed, inertia is created in the counterweight, and this causes the spindle to both rotate and oscillate. As the electric motor spins the free rotating spindle assembly and thus pad rotation and pad oscillation are maintained via the inertia created by the counterweight.

The free rotating spindle assembly is NOT directly or solidly connected to the counterweight and for this reason there is slippage.

This slippage shows up to our eyes as the buffing pad is not rotating or oscillating. And most of the time instead of seeing pad oscillation and rotation, you see the pad simply stalling out and vibrating or jiggling against the paint surface.

Because of this slippage, there is no distinct and/or forced rotation/oscillation and therefore any orbital action is random.

The upside to a free spinning random orbital polisher

A lot of people new to machine polishing and with little or no experience, are afraid they are going to burn-through-the-paint. Or cause some other type of damage like twisting the paint. But with the slippage aspect for this type of polisher, if you press too hard on the tool, or hold the pad at an angle to the paint surface, instead of causing damage, the pad will simply stop or slow down pad rotation and pad oscillation. Thus this is a very safe type of tool for people of all background experience.

The downside to a free spinning random orbital polisher

While some will argue this fact, (I no longer argue with people), anytime the pad is not rotating and oscillating, in other words, when the pad is merely vibrating or jiggling against the paint surface, you are not doing anything.

Or more specifically, you are not removing paint thus you are not leveling the surface and thus removing defects out of the paint. As I like to say, you are wasting your time.

Brain Drain

Another downside to a free spinning random orbital polisher is the brain drain that comes with running this type of tool for hours.

Let me explain. When running this type of tool, if you look at the back of the backing plate and the buffing pad, without some type of mark, it can be difficult to see if the pad is rotating/oscillating or stalling out. When you look at an unmarked backing plate and/or pad, what you see is a blur of motion.

To make it easier for your eyes to see and monitor pad rotation/oscillation, a technique professionals use is to somehow mark the backing plate and/or edge of the buffing pad. For light colored backing plates and pads you can use a black sharpie marker. For dark colored backing plates and/or buffing pads you can use a silver, white or gold marker.

Marking light colored backing plates with a black marker

You can also place some marks on the pads themselves.

For black or dark colored backing plates, use a light colored marker like silver or gold. You can even use light colored automotive touch-up paint or even fingernail polish. Heck, I’ve even used White-Out, a white colored type of paint used in the old day to fix typing mistakes back before computers when the majority of people were using typewriters and paper.

Adding this simple mark will now make it easier for your eyes to look and see if the pad is rotating or not. Then the idea being, if you do in fact see pad stalling, (because the mark is not rotating or oscillation), you can try to remedy the situation by,

- Make sure you’re holding the pad flat to the surface.

- Increase the speed setting on the polisher

- Switch to a clean DRY pad

Sometimes making the above changes helps and sometimes it doesn’t help.

What Does Brain Drain mean?

If you accept that marking the backing plate and/or side of the buffing pad as a fix to better enable your eyes to see and monitor pad rotation/oscillation, doesn’t this then mean that the ENTIRE time you’re going to buff out a car with this type of tool you MUST concentrate and LOOK at the backing plate and buffing pad to see in fact if the pad is rotating and oscillating or – stalling out.

A Deeper Look

Let’s say you’re going to do the paint correction to a 2014 Chevy Camaro that is totally swirled-out and filled with scratches. Let’s say you’re going to use a Porter Cable 7424XP. Assuming you don’t take any breaks, let’s assume you’re able to do all the paint correction to all the body panels, roof, hood, trunk lid, fenders and doors in approximately 4 hours. In my experience, this would be a minimal amount of time for a car this size and 6 hours would be more accurate for the average person with skill and experience using a Porter Cable 7424XP

Doesn’t this then mean, you have to LOOK to SEE and MONITOR if the pad is rotating and oscillating for this entire time? Look, see and monitor for pad rotating for 4-6 hours? I call this Brain Drain. Constantly looking for pad rotation and monitoring how you’re holding the tool, the speed you’re on and the curvature of any given panel drains your brain.

Most people don’t notice this until they read an article like this and then think about it. Maybe that’s you right now? Or perhaps you’ve watched a video or taken one of my detailing classes where you’ve heard me explain this aspect for using free spinning random orbital polishers.

It’s up to you and your style for doing paint correction but for me? I much prefer to use a gear-driven orbital polisher and think about what I want to think about as I buff for 4-6 hours versus being (practically) forced to look and see and monitor pad rotation/oscillation for 4-6 hours. It’s truly mind-numbing.

These types of tools (free spinning random orbital polishers), work best on large flat surfaces. As soon as you need to buff on a curved body panel, either concave or convex, because there will be different amounts of pressure applied to isolated portions of the face of the buffing pad – the pad will tend to stall-out. Because you cannot flatten out curved body panels, you’re stuck trying to maintain pad rotation/oscillation when buffing these portions of the body panel.

Outside of switching to a smaller free spinning random orbital polisher with a smaller backing plate and thus smaller pad, there’s not much else you can do to power through curved body panels without pad stalling. And even when you do switch to a smaller free spinning random orbital polisher with smaller diameter buffing pad to buff curved panels or thin panels – these types of tool are still inherently weak, and thus you will always have to combat pad stalling.

The Walking Effect versus Smooth Sailing

Oftentimes you’ll see, read or hear someone describe what is called the walking-effect or the pulling characteristic for gear-driven orbital polishers. Just to note, rotary polishers also have this pulling effect. The majority of time I see someone reference the walking or pulling effect it’s in a negative connotation. Basically they are complaining about how the tool feels when they are using it.

What causes the walking effect?

When using a gear-driven orbital polisher, if you’re not holding the face of the buffing pad completely flat against the painted surface, any side of the pad that is getting more downward pressure will tend to grab the surface MORE and this will translate through the tool to you, (your hand and arms), as the tool pulling or trying to walk in a specific direction.

This feeling is called POWER. This type of tool has a LOT of power, just like a rotary polisher has a lot of power.

With a free spinning random orbital polisher, because there’s always some level of slippage taking place, the tools always feel SMOOTH and you’re running it over a surface. At least a lot smoother than the walking effect you can feel from a gear-driven orbital polisher. This at its core is LESS power.

When I see or hear someone complaining about the walking-effect, what I hear them saying is they don’t like all the power. Instead, they would like a weaker tool because it’s smoother.

Both opinions, some people like the power, and some people prefer a smooth feeling tool, are valid. And I learned a long time ago, my STYLE for doing paint correction is often times different than other people’s style for doing paint correction.

The way my brain thinks goes like this,

Detailing a car from start to finish takes a long time. If you count starting the day by washing the car, then claying the paint, then doing the paint correction steps, then somehow sealing the paint with a wax, synthetic paint sealant or a ceramic coating, it will take most people all day. We’re talking a long day, 8-12 hours.

And don’t forget all the little stuff like cleaning the wheels and tires when you wash the car, this takes around an hour. Later dressing the tires and cleaning the glass inside and outside as the finishing step.

Detailing a car from start to finish takes a long time

It takes a long time to go from start to finish to fully detail a single car – why would I want to do it in any way that takes LONGER? The answer is, I don’t want to do it in any way that takes longer, and this is why I opt for a gear-driven orbital polisher over any brand of free spinning random orbital polisher. Overall – it’s simply faster.

The upside to a gear-driven orbital polisher

Plenty of direct drive, or gear-driven power means the pad is going to oscillate and rotate no matter what the shape of the body panel, how you’re holding the pad to the surface, the speed setting, the type of pad – anything and everything. It just doesn’t matter because this type of tool is going to maintain pad rotation and pad oscillation no matter what -and this means you can plow through the paint correction step as fast as humanly possible without wasting time, energy or brain power and while also maintaining professional quality results.

The downside to a gear-driven orbital polisher

The walking-effect is a deal-breaker for some people and these types of tools also tend to be heavier, (only by a pound or two). The original gear-driven orbital polisher is the FLEX XC 3401 VRG and the MSRP is approximately $450.00 putting it out of reach for the weekend warrior, but the good news is the Harbor Freight version sells for $120.00. Of course the FLEX version comes with more bells and whistles, so let your own pocket book be your guide.

Best Polishers for Beginners (Under $200)

Below are the polishers we’ll be looking at and their prices at the time this article was written from the lowest price to the highest price. I will also go over free spinning orbital polishers first as these all operate in the same way. After free spinning polishers, I’ll go over the least expensive gear-driven orbital polisher on the market at this time.

Best Free Spinning Random Orbital Polishers for Beginners

Recommended: Griot’s Garage G9 Random Orbital Polisher – $169.99

https://www.griotsgarage.com/g9-random-orbital-polisher

Well-built, quality polisher. The team at Griot’s Garage really did a great job creating a user-friendly, power tool. I personally know some of the people behind the design and creation of the BOSS tools and they are all solid, high-caliber people with years of real-world detailing experience. We’re not talking about marketing people, we’re talking about getting-your-hands-dirty and doing the work to detail cars for decades.

Their opinions and ideas matter and Richard Griot and his son Nick listened to the input of my friends Jeff Brown, Rod Kraft as well as the rest of their team and the end results are pro-quality tools you can trust to get the job done and last for a lifetime. If they ever do break, Griot’s stands behind their products with a lifetime guarantee.

In my opinion, for most people and certainly for everyone new to detailing and specifically paint correction, short stroke random orbital polishers like the Griot’s G9, which is a 9mm orbit stroke polisher, are a wiser choice than their counterparts, long stroke free spinning random orbital polishers.

Why? Because it’s easier to maintain good pad rotation with a short stroke polisher versus a long stroke polisher. It has to do with the outer edges of a spinning buffing pad and the leverage the outer edges have over the spindle that spins the backing plate. The larger the stroke, the larger the pad, the more leverage the pad has over the driving force that rotates and oscillates the pad.

Conversely, the shorter the stroke and the smaller the pad, the less leverage the outer edges of a spinning buffing pad has over the spindle. Thus in a world where there is a lot of focus on long stroke polishers, the fact that Griot’s continues to offer a quality short stroke polisher shows they know all this stuff too well.

The G9 in the tool name stands for a 9mm orbit stroke length. This is only 1mm larger than the Porter Cable polisher they introduced to the enthusiast and pro detailing world back in the 1980s. It’s also only 1mm larger than the infamous GG6, which was the Griot’s version of the Porter Cable that sold for years if not decades. The GG6 or Griot’s Garage 6” Dual Action Polisher would have been more aptly named the GG8 as the number 8 stands for 8mm, which was the orbit stroke for this tool Like a lot of companies, back when Griot’s was offering the GG6, it was named thusly because it came with a 6” diameter backing plate.

As previously discussed, the size of the backing plate, while important, has nothing to do with the action of the tool. That’s all in the rearview mirror now and you can see by the current naming protocols, Griot’s now names their tools by the action of the tool, not the size of the backing plate.

The 9mm orbit stroke length is the perfect balance between too small and too large for beginners. 9mm orbit stroke length offers plenty of correction ability to remove swirls, scratches, water spots and oxidation while also being easy to maintain great pad rotation/oscillation.

The tool itself is ergonomic in its design with plenty of built-in features to make this a best-in-class polisher for both beginners and professionals alike.

| PROS | CONS |

|---|---|

| Maintains pad rotation more easily | None |

| 9mm orbit stroke for powerful correction | |

| Ergonomic design reduces strain | |

| Extremely user friendly |

| Technical Info |

|---|

| 9mm orbit stroke |

| Speed – 2000 to 6400 OPM |

| 6 speed settings |

| 10’ quick-connect 18 AWG SJO rubber power cord |

| Fan-cooled counter-balance |

| 1,000 Watt, 8.5 amp motor |

| Speed dial accessible to right and left-handed users |

| 5/16” UNF Fine Thread |

| Shroud grip contoured to accommodate four fingers |

| Rest pads for tool to lay stable on its back |

| Quick access brush side ports |

| Includes 14mm backing plate wrench and replacement high-carbon brushes |

| Convertible to a 5″ pad system with optional 5″ Vented Orbital Backing Plate |

| Double-shot rubber platypus head-grip |

| Premium bearing construction |

| Constant speed control |

My Comments

I still have one of the first G9s available in the U.S. market given to me by my long-time friend at Griot’s Garage, Doug Hodge, (since retired). It still works just as well as the day I was given it back in September of 2019.

It’s smoother and more powerful than both the Harbor Freight 6” DA and the Porter Cable 7424XP at a price point that’s only a few dollars more than the Porter Cable 7424 but still under $200.00 And with the lifetime guarantee and industry setting proactive customer care, it’s really a great value for your hard-earned dollars.

Besides the tool, Griot’s also offers a complete line of microfiber and foam buffing pads in sizes that fit all the Griot’s Garage polishers and backing plates, which are purpose-tuned to their tools.

Recommendation

If you’re looking for a great, all-purpose free spinning, random orbital car polisher that won’t break the bank and offers more power and a much smoother operating experience than either the Harbor Freight or Porter Cable short stroke polishers, then I would wholeheartedly recommend the Griot’s G9.

Runner-Up: BAUER 5.7 Amp 6 in. Short-Throw Random Orbit DA Polisher/Sander – $64.99

https://www.harborfreight.com/57-amp-6-in-short-throw-random-orbit-da-polishersander-64528.html

This is easily the best bang for your buck when it comes to a cheap, free spinning random orbital polisher. This is a knock-off of the once very popular Porter Cable 7424XP. It costs around half as much as a Porter Cable 7424XP but has a LOT more power.

Some people complain that it has too much vibration and is too loud under full speed operation. This can be improved by removing the factory grease and replacing it with a premium quality lithium grease, which I’ll share in a separate article/video.

Like the Porter Cable 7424XP, the Bauer polisher when compared to most other polishers is compact in size making it easy to use anywhere on the car. It’s easy to grip with both hands and if needed, it can be held with just one hand, for example, machine applying a wax.

The 8mm orbit stroke length is perfect for removing swirls and scratches and because this is a SHORT stroke polisher, it’s a lot easier to maintain good pad rotation compared to long stroke polishers. Maintaining pad rotation and pad oscillation is crucial for fast and effective defect removal and this is important for anyone that is new to machine polishing.

With the 5/16 fine thread spindle, you can attach different size backing plates for example, 6”, 5” and 3” backing plates.

The smaller 3” backing plate enables you to use 3.5” and 4” buffing pads and this works better for buffing thin panels, (to avoid buffing on top of raised body lines or edges), and also works better for buffing inside concave curved body panels.

The only downside to a 3” backing plate and thus the smaller pad is it makes the tool tippy. By the word tippy I mean, the tool body itself is much larger than the small 3.5” buffing pad so you have this larger tool, over the top of a small spinning pad and it simply makes the tool tippy. When using a small backing plate and small buffing pad, you definitely want to have a strong grip on the tool and control the buffing pattern.

The factory 6” backing plate in my opinion is too large as this forces you to use larger 6.5” and 7” buffing pads and the diameter size and thickness of pads this size tend to absorb a lot of the energy coming out of the tool and dissipate it. This shows up as weak or anemic pad rotation/oscillation.

The optimum backing plate size is 5” as this allows you to use 5.5” buffing pads and this size is the best all-around size for maintaining great pad rotation/oscillation for the most time effective defect removal.

This tool comes with a side handle, also called a stick handle, and it can be attached on either side of the head of the tool. My strong recommendation is to simply throw the handle away because when newbies just starting out use the handle, they tend to push harder on the handle, and this causes the pad to press against the body panel at an angle.

Holding the tool and thus the pad against the surface at an angle decreases pad rotation/oscillation. What works better to maintain good pad rotation/oscillation is to place one of your hands on the head of the polisher with your other hand on the body of the tool. With these hand positions, it’s dramatically easier to maintain EVEN pressure on the head of the tool and thus maintain the pad flat to the surface.

Besides using this tool for paint correction, you can also use it for sanding wood, car paint and gelcoat boats. While not super effective, you can also attach scrub brushes to the tool or the backing plate and use this to machine scrub surfaces.

My Recommendation

If you’re brand new to detailing, this is a great entry level tool. You can gain a lot of experience doing paint correction with this tool and as you gain experience and confidence you can decide if this is all the polisher you need, or add a new, more powerful tool to your detailing arsenal.

With an average retail price of $65.00, and even cheaper if you purchase during a sale, this is a very low cost way to get into car detailing and paint correction. If you do purchase this tool, I strongly recommend spending the extra money you save and purchase a 5” backing plate. A 5” backing plate that fits this tool can be easily found on Amazon.

If you don’t get the 5” backing plate, you are forced to invest your pad money into 6.5” and larger buffing pads and at some point you’ll learn I am correct about the smaller 5” backing plate and 5.5” buffing pads being a better fit for this type of tool. If you make the switch later, all the money you spend on larger pads is more or less wasted. So get the smaller 5” backing plate and right from the start, invest you pad money into smaller and even thinner buffing pad for optimum pad rotation/oscillation.

What about the long stroke Harbor Freight polisher?

Great question. In the video that goes with this article, I cover this tool and recommend NOT starting with this tool. I included it in this article and the video because I know some of you, after reading this article and/or watching the matching video, will head down to Harbor Freight to check out the above Harbor Freight 6” Short Throw DA Polisher and you’ll SEE this tool, the BAUER 7.5 Amp, 6 in. Long-Throw Random Orbit DA Polisher.

| PROS | CONS |

|---|---|

| Powerful for an 8mm orbit stroke | Heavy vibration on hands |

| Inexpensive | Loud noise while operating |

| Compact size | Pad stalls (like all free spinning tools) |

| Interchangeable size backing plate |

| Technical Info |

|---|

| 8mm orbit stroke |

| Speed – 2000 to 6400 OPM |

| 6 speed settings |

| 10’ Power Cord |

| 120 Volts |

| 5.7 Amps |

| 5.6 pounds |

| 5/16” UNF Fine Thread |

| Two position auxiliary handle (left and right) |

| Power lock slide switch |

| 6” hook and loop backing plate |

2nd Runner Up: PORTER-CABLE 7424XP Car Polisher and Buffer, 6-Inch, Orbital, Variable Speed – $139.00

https://www.amazon.com/PORTER-CABLE-7424XP-6-Inch-Variable-Speed-Polisher/dp/B002654I46

| PROS | CONS |

|---|---|

| Decades of proven quality and reliability | Weakest polisher in this list |

| Safe for entry level detailers | Low quality electronic speed adjustment dial |

| Can use multiple backing plates | |

| Works for paint correction, sanding and scrubbing | |

| Lightweight, compact size |

| Technical Info |

|---|

| 8mm orbit stroke |

| Speed – 2500 to 6800 OPM |

| 6 speed settings |

| 10’ Power Cord |

| 120 Volts |

| 4.5 Amps |

| 5.5 pounds |

| 5/16” UNF Fine Thread |

| Two position auxiliary handle (left and right) |

| Power lock slide switch |

| Single use backing plate & pad combination |

Before Harbor Freight knocked the Porter-Cable 7424XP off, the “PC” was the go-to free spinning random orbital polisher in both the enthusiast and professional detailing world. It doesn’t have the same power as the Harbor Freight version and when it comes to this type of tool, you really want all the power you can get to help you to maintain pad rotation/oscillation.

The other thing I don’t like, and a lot of other people don’t like about the PC is the electronic variable speed dial. With most variable speed dials, as you turn the dial to change the speed setting you can feel and hear the motor speed increase or decrease. With the PC, there’s very little difference between the 1, 2 and 3 speed settings. You can feel and hear an increase in speed when you turn the dial from one of these lower speed settings to the 4, 5 and 6 speed settings. It’s not a huge deal, but it seems like a simple fix that Porter Cable could implement if they wanted, but they choose not to do so. And yes, I have spoken to a key engineer at Stanley Black & Decker, the company that owns Porter Cable.

I like the quality fit and finish of the tool itself. I also like the compact size and lightweight. I think it runs smoother, that is less vibration than the Harbor Freight knock-off but the difference in vibration isn’t enough to make a person choose it over the Harbor Freight version.

The PC has a stellar reputation for being an absolute TANK for a tool. You could drive over this with a truck and pick it up off the ground and go right back to work with it. The thing simply won’t die. The compact size and weight, and overall smoothed over tool body makes it easy to hold, maneuver and use for hours.

I’ve personally used a PC to not only buff out hundreds of cars over the decades but also to machine sand paint to remove orange peel as well as machine sand gelcoat boats to remove severe and deep oxidation and also dock rash.

Recommendation

I hate to say this, but if you’re contemplating either the Harbor Freight or the Porter Cable as your first car polisher, I would recommend the Harbor Freight 6” DA Polisher over the Porter Cable 7424XP. The extra power you get with the Harbor Freight version of the PC makes it much easier for the average person and especially a newbie to maintain pad rotation/oscillation and this is the most important aspect about ANY type or brand of free spinning random orbital polishers.

Take the money you save buying the Harbor Freight 6” DA Polisher and purchase a 3” and 5” backing plates and pads to fit both backing plates. If you don’t like the noise and vibration, remove the factory greatest in the head unit and replace it with a top quality brand of lithium grease.

Not Recommended: BAUER 7.5 Amp, 6 in. Long-Throw Random Orbit DA Polisher – $79.99

https://www.harborfreight.com/75-amp-6-in-long-throw-random-orbit-da-polisher-56367.html

As I state in the video, long stroke orbital polishers take more technique and practice to maintain good pad rotation and pad oscillation. Large stroke and large pads are great for large flat surfaces, like the roof, but most cars have a lot of body designs and curves, and this is where you will struggle to maintain pad rotation.

It’s MUCH easier to maintain good pad rotation/oscillation with a short stroke polisher than a long stroke polisher. This is why in this list of free spinning random orbital polishers, I put the focus on all short stroke polishers. I did want to reference this because I know you’re going to see it and have questions.

I go more into the details as to why I don’t recommend any brand of long stroke free spinning random orbital polishers for beginners in the video – if you want more information. And just to add, the BAUER 7.5 Amp, 6 in. Long-Throw Random Orbit DA Polisher is a 20mm orbit stroke.

Best Mini Free Spinning Random Polisher for Beginners

Recommended: Griot’s Garage G8 Mini Random Orbital Polisher – $144.99

https://www.griotsgarage.com/g8-mini-random-orbital-polisher/

| PROS | CONS |

|---|---|

| 3″ backing plate for thin panels | None |

| Optional 2″ backing plate for thinnest panels | |

| Maintains pad rotation even on sharp, concave curves | |

| Greater precision than larger polishers | |

| Lightweight, compact size |

| Technical Info |

|---|

| 8mm orbit stroke |

| Speed – 2000 to 6400 OPM |

| 6 speed settings |

| 10’ quick-connect 18 AWG SJO rubber power cord |

| Fan-cooled counter-balance |

| 700 Watt, 6-amp motor |

| Speed dial accessible to right and left-handed users |

| 5/16” UNF Fine Thread |

| Shroud grip contoured to accommodate four fingers |

| Rest pads for tool to lay stable on its back |

| Quick access brush side ports |

| Includes 14mm backing plate wrench and replacement high-carbon brushes |

| Fitted with 3″ vented orbital backing plate |

| Ergonomic design dampened with double shot rubber |

| Premium bearing construction |

| Constant speed control |

| Fully variable speed trigger throttle with trigger lock |

| Includes 2″ orbital backing plate |

My comments

To me, this is really the tool to have for exactly what it’s intended to do and that’s to tackle all the small stuff. I would not recommend this for your only or first polisher, but as an additional polisher to your full size polisher.

I do know some people do in fact use this to buff out entire cars, but realistically, tackling the hood or any body panel that needs serious paint correction with a 3” pad is simply not time-efficient. That said, I also know people that have physical limitations are unable to hold and use large format tools for extended periods of time and for these people, this smaller, more compact but still easy to hold polisher might be just the solution they’ve been looking for.

Recommendation

Because of the quality design, power and performance, I would wholeheartedly recommend this tool for anyone’s detailing tool collection. There’s an old saying that goes like this,

“Use the right tool for the job.”

When you need to buff out thin panels without the risk of buffing on an edge or raised body line, or anytime you’re buffing tight or intricate areas or components, the right tool for the job is the Griot’s G8. You will see what I mean about buffing out thin panels, intricate or tight areas in the video.

Best Gear Driven Orbital Polishers for Beginners

Recommended: HERCULES 8 Amp 6 in. Forced Rotation Dual-Action Polisher – $119.99

https://www.harborfreight.com/8-amp-6-in-forced-rotation-dual-action-polisher-59561.html

| PROS | CONS |

|---|---|

| Gear driven pad rotation – no stalling | Can be difficult to control |

| Cuts paint quickly and efficiently | Higher learning curve than free spinning DAs |

| Finishes out swirl-free | Does not include 7-function microprocessor (standard on Flex equivalent) |

| Inexpensive |

| Technical Info |

|---|

| 8mm orbit stroke |

| Speed – 3200 to 9600 OPM |

| 6 speed settings |

| 25′ power cord |

| 120 volts |

| 8 amps |

| 6.3 pounds |

| Forward bail handle |

| 6″ backing plate |

My comments

As a long-time user of all the FLEX 8mm gear-driven orbital polishers, I have to say, I was impressed with this inexpensive knock-off of the FLEX XC 3401 VRG also known as the BEAST. I expected it to be inferior in every way, but I was wrong. It’s smooth, quiet and powerful. It’s a pretty exact clone of the BEAST but there are a few places they cut corners.

The backing plate bolt and two washers, one flat and one locking are sub-standard in quality but could easily be replaced with better components.

The Harbor Freight Forced Rotation Dual Action Polisher does not offer the 7-function microprocessor that comes standard with all FLEX polishers.

The Seven Functions of the FLEX 7-Function Microprocessor:

- Provides constant speed control via the tachometer generator.

- Provides a soft, gradual start of the rotation of the electric motor that powers the drive mechanism.

- Controls the accelerator trigger switch.

- Provides restart protection after a power interruption.

- Provides overload protection.

- Monitors the temperature of the coil windings and turns the polisher off before damage can occur.

- Controls speed set by the variable speed dial.

One of the most important functions is the heat sensor, which monitors tool temperature. If the tool becomes too hot, the 7-function microprocessor will turn the tool off so no damage can occur.

Another key benefit to the 7-function microprocessor is the power interruption function. If power goes off to the tool, when power is restored, the tool will NOT turn back on until you release the speed trigger lock. This prevents the tool from turning on and possibly causing damage to a vehicle or a person.

The Harbor Freight version of the BEAST has none of these features. Besides that, this tool works as advertised.

Recommendation

If you’re a beginner, and completely new to using any type of polisher, the Harbor Freight Forced Rotation Dual Action Polisher is a handful to learn how to use and master as your first tool. I’m not saying some people are unable to do this, I’m just warning you ahead of time, it’s a very powerful tool and you’ll need to spend some time getting used to it before knowing if it’s the right tool for you.

If you’re in strong physical condition and gripping onto a polisher to control it for hours doesn’t bother you, then I would strongly recommend taking a strong look at this gear-driven polisher. The good news is, Harbor Freight has a very good 90 day warranty and excellent customer service.

This means you can purchase this tool, test it out for 90 days and if you find it’s not the tool for you, simply return it. Just be sure to keep your receipt and I would suggest keeping the original box and any items that came with the tool, in the box.

Probably 60% of my paint correction work is performed with the FLEX XC 3401 VRG aka the BEAST. The other 40% is done primarily with the rotary polisher and when working on soft paint or soft plastics, a free spinning random orbital polisher like shared in the first part of this article.

So yes, I’m a huge fan of this type of tool, 8mm gear-driven orbital polishers and the Harbor Freight Forced Rotation Dual Action Polisher is an inexpensive option compared to the famous BEAST.

If you’re a professional, I would recommend investing in the actual FLEX BEAST, and another strong recommendation would be, for any tool you consider your primary tool, it’s always a good practice to have a backup of the same polisher. This way if something does go south with a tool in the middle of a detail, you’re not dead in the water.

Which Polisher is the Best Value?

Realistically, the only way to know for yourself which tool is the best bang for your hard-earned bucks is by holding them in your hand and using them on multiple cars. The only downside? You’ll have to purchase any tool you’re interested in. That is, unless, you take one of my detailing classes here in Stuart, Florida. I have ALL these tools and more available for testing during my 1 and 3-Day Classes. You can get more information and sign-up here.

Summary

I know the above is a lot to chew through. I think you’ll find the video will fill in any gaps you don’t find via the above text and pictures.

Weekend Warriors

If all you ever plan to do is detail your own car or cars, chances are good you’ll probably only need a polisher once or twice a year. For this low frequency of use, a budget polisher makes sense. I own and have used extensively all the polishers in this article and I’m comfortable telling you, any one of these will be a great choice and will get the job done.

Future Professionals

If you’re just starting out but you’re toying with the idea of gaining experience and increasing your skill and comfort level doing machine polishing, I would still recommend one of these entry level polishers. Being under $200.00, it’s not a huge investment and if after buffing out a few cars you find you enjoy this type of work, you can always add more polishers to your arsenal.

If I could pick just one polisher out of the list?

Keep in mind, I’ve been detailing cars and specifically doing machine paint correction since the 1970s. As I write this article in 2024, that’s over 40 years of experience using pretty much all the common and popular polishers on the market today. In fact, I’ve done a lot of prototype testing for,

- FLEX

- RUPES

- Makita

- Dynabrade

- Milwaukee

- DeWALT

Because I do have a lot of experience, out of the polishers included in this article and the matching video, I would choose the Harbor Freight Forced Rotation Dual Action Polisher.

I like to get in and get out

I like to knock out my car detailing projects as fast as humanly possible while keeping my results professional quality. I don’t like having to look at the backing plate or pad constantly as I machine polish a car to see if the pad is rotating and oscillating, or just jiggling or vibrating against the paint. So for me, it’s a gear-driven orbital all the way.

By the way, if you want to read my full review for the Harbor Freight Forced Rotation Dual Action Polisher, which I tested out by buffing out a 1959 Rolls Royce Silver Cloud with a recent $50,000 dollar paint job, you can find it here,

Review: Harbor Freight Forced Rotation Dual Action Polisher

Final thoughts…

I hope this review of this collection of sub-$200.00 tools has helped you. I’m always available if you have questions. I would also strongly recommend taking one of my classes, especially if you find yourself to be the kind of person that learns better by doing, versus sitting in a chair looking at a PowerPoint presentation while the instructor drones on and on and on.

My classes don’t roll like that. We start early at 7:30am and the FIRST tool you will get hands-on time with is the rotary polisher and it only gets better from there. At the bottom of this article I’ll include recaps of my most recent classes. Click the links and look at the pictures. All you will see are happy people having fun working on actual cars and boats. We never use demo hoods in our classes because training on the real-deal, an actual car, has tremendously more IMPACT when it comes to comprehensive learning. You’ll also see, I tend to bring in really cool cars for you to train on. 🙂

Questions? Comments?

If you have further questions and/or comments, please add them to this article. You can also reach out to me via email, text or phone.

I hope to see you in a future detailing class!

Sincerely,

Mike Phillips

Chief Education Officer for Dr. Beasley’s

760-515-0444

Great write-up and I agree with all your recommendations/conclusions.

I just do my own Corvettes, but have been correcting my 2001 black C5 since I bought it new in 2000 – still looks like new!

I started with a Porter Cable from Griot’s back in 2001. Upgraded to “The Beast” after a few years. Then I had problems with the Flex – the plastic gear teeth were getting chewed up and the trigger switch died (after maybe a total of 12 hours on the machine!). I sent the Flex to an authorized repair facility in Dallas and they took over six months and several phone calls to get it returned. Also the repair was over $200!

This sent me looking for an alternative. I went with the Griot’s BOSS 15″ throw. I also later added the Griot’s G8 3″ and more recently added their new Boss Hybrid Micro Polisher (a Corvette owners dream tool for getting into tight spaces). Just wish I had all my current tools back in 2001, I would have more clear coat left!

Hi John,

Thank you for reading and commenting on this article. I have to admit, I’m also happy to hear that your experience is similar to mine.

Sorry to hear about the bad experience with the turn-around time for getting your FLEX repaired.

I was recently had a person make a comment about the plastic gears in a YouTube video we mad on

Which Forced Rotation Polisher Is BETTER? Harbor Freight Hercules vs. Flex XC 3401 VRG

https://www.youtube.com/watch?v=AV5edKszDEU&t=151s

Here’s the comment,

@btbd2785 – 1 month ago (edited)

Why do they make the gears put of plastic? The price you pay for a “German” high quality machine , they could have least make then out of metal. I can see the Hercules being made off plastic because of cost, but Flex too?

Here’s my answer

@mikephillipsrealworlddetailing – 3 days ago

@btbd2785 – Gotcha. My guess is the ENGINEERS know their job, kind of like we both know our jobs. I’ve been using the BEAST polisher since 2009 and I’ve NEVER seen the plastic gears break or wear-out. Never.

So your experience having the plastic gear teeth getting chewed up from use is the first time I’ve ever heard of this?

The only reason that I can think of besides maybe you got a Lemon, is if the bolt that holds the backing plate to the spindle comes loose, then the gears can slop around instead of meshing correctly.

The only other reason I think this can happen, again, unless you got a Lemon, is if the bolt is replaced with a longer bolt and this would cause sloppy fitment between the gears under operation.

So thanks for sharing this and the next time I talk to Chris Metcalf at FLEX I’m going to ask him if he sees this as a common problem?

I’ve had a LOT of FLEX 3401 polishers in my classes for the last 15 years and talk with a lot of people in this industry and you experience is the first time I’ve ever heard of this as a problem. So thanks for sharing.

Hopefully, it won’t happen again. :)

Thank you!

Mike Phillips

Hi Mike, Weekend Warrior here.. Got your article read done a few days ago… Harbor Freight just had a $89 sale on the forced rotation dual action polisher. I took the plunge even though it’s got some usage cons for beginners, I’m a big guy 6’2″ 250lbs. I’m in decent enough shape I think I’ll be able to control it on my small SUV, but will find out as the weather warms up a little! Thanks for doing these great articles, watched your video on the “Silver Cloud” before deciding as well. Peace!

Hi Douglas,

Thank you for watching the video and reading the article. Nowadays, there’s SO MUCH information on the Internet via YouTube, Blogs, Facebook, Instagram, TicTok ect., so anytime someone not only takes the time to read or watch any of our content but then to take the time to share their thoughts – well take my word for it, I do appreciate it.

The Harbor Freight copy of the FLEX BEAST so far has been a capable tool. It takes a little time to get use to the pulling aspect, but keep in mind, the pulling is POWER. Free spinning, random orbital polishers DON’T have the pulling effect or what other’s call the walking-effect because they don’t have the power.

Instead of pulling, they just stall out and that makes buffing with these types of tools smoother but any paint correction job is going to take a lot longer and of course, there’s always the Brain Drain that goes with watching and monitoring for pad rotation or pad stalling for the entire time you’re buffing out a car.

And just to note, buffing out that 1959 Rolls-Royce was a TON of work. The entire paint job was filled with sanding scratches and not just in the larger flat areas but around every edge, raised body line and body molding accents. I cut it HARD with a rotary and a wool pad using the Dr. Beasley’s NSP 150 and after finally removing all the sanding marks with the rotary, then I was able to switch over to the Harbor Freight Hercules Forced Rotation Polisher. Was so happy to see it leave. LOL

If you run into any issues, just give me a call, I would be more than happy to help where I can.

Mike Phillips

Cell: 760-515-0444

Thanks for the fantastic, informative article, Mike. I’m new to detailing and enjoyed it. What model and backing size would you recommend for a beginner working on a 1967 VW Beetle, which has a lot of body curves to it? After reading your article, I’m leaning toward a gear driven because I feel I would spend too much time trying to keep a random orbital in correct contact with the curved body panels. Would a 5 inch backer be the best size to mainly use on my vehicle or what would you recommend? As a beginner, are there any questions I’m forgetting to ask? Thanks for all your help.

Hi Jeff,

Generally speaking, if using a FREE SPINNING random orbital polisher, I would get a short stroke option as it’s easier to maintain pad rotation. With the long stroke options, the out edge of the buffing pad has greater leverage over the spindle and when buffing curved or thin panels, it’s really difficult to maintain pad rotation and pad oscillation thus no work gets done.

The Porter Cable and the Harbor Freight 6″ DA are basically the same thing, they are both 8mm free spinning random orbital polishers. I much prefer the build quality and performance of the Porter Cable over the Harbor Freight, but the Harbor Freight is cheaper, and most towns have a HF store.

JB Tools normally has the best price on the Porter Cable, but it looks like they are out of stock.

Porter Cable 7424XP 6″ Variable Speed Random Orbital Polisher – $99.00

https://www.jbtools.com/porter-cable-7424xp-6-variable-speed-random-orbital-polisher/

Whichever you purchase, with the Porter Cable you must buy a 5″ backing plate separately. The Harbor Freight version comes with a 6″ backing plate but this forces you to purchase 6.5″ and 7″ pads, and these are simply too larger for this type of tool to get any type of paint correction performance. Thus, you really need to purchase a 5″ backing plate for this polisher also.

CASOMAN 5-Inch DA Polisher Backing Plate $9.97

https://www.amazon.com/CASOMAN-5-Inch-Polisher-Sander-Pad/dp/B07NTNFMG9/

With a 5″ backing plate you can use my favorite pads, the Buff and Shine EdgeGuard 5″ pads.

Buff and Shine 5″ EdgeGuard Pads

https://drbeasleys.mystagingwebsite.com/shop/accessories/pads.html

If you really want to get in and get it over with, then get the Harbor Freight Forced Rotation Dual Action Polisher, which is an 8mm GEAR DRIVEN orbital polishers.

Here’s my review.

Review: Harbor Freight Forced Rotation Dual Action Polisher

https://drbeasleys.mystagingwebsite.com/blog/2024/03/09/review-harbor-freight-forced-rotation-dual-action-polisher

With this polisher you’ll want to get the 6″ Buff and Shine EdgeGuard buffing pads.

With a gear-driven orbital there’s ZERO pad stalling, because it’s gear-driven and this makes it faster and easier to buff curved panels like you have with your VW.

Cool car by the way, my sister had a 66 VW Bug back when I was in high school, it had the Automatic Stick Shift, and it always ran great and the transmission worked great too.

Thanks for reading!

Mike Phillips

Hi, Mike. I just posted my last comment and then saw your reply. That’s the great thing about bugs; everyone of a certain age has a story about one.

Thanks for your help. I appreciate it. Keep up the great work.

After reading this article and your review on Harbor Freight’s Hercules, that’s what I’m strongly considering. In addition to my question on the backing plate size(s) to use, what brand of buffing/polishing/etc. pads should I get?

FLEX makes a 5″ backing plate for thier polisher but it will fit on the Harbor Freight copy. I wouldn’t get it and never use them myself.

With the Buff and Shine EdgeGuard pads, the shape of the outer edge enables you to buff close to adjacent panels safely and also to get into tight areas. These are my go-to pads. If your 1967 VW Bug has oxidized paint, I’m guessing it might be single stage? If so, you could probably get away with a few of the yellow 6″ Buff and Shine EdgeGuard pads.

Mike

Would you recommend a long throw for large flat surfaces like campers/RVs with gel coat fiberglass or would a gear driven still be preferred?