Last Updated June 12, 2025

Doing a major paintwork correction on a car with deep swirls, scratches, water spots and/or oxidation often requires something called a “compound” or “rubbing compound” that cuts paint faster and more aggressively than a polish.

There are a lot of different compounds on the market today using a lot of different technologies. In this article, I’ll explain the three different kinds of paint correction products, why compounds are more aggressive than polish, what to look for in a compound and my recommendations for compounds from both Dr. Beasley’s and other brands.

Compound vs. Polish vs. AIO: What’s the Difference?

In the world of automotive paint correction there are three types of abrasive products. The abrasive product is the product you apply to the pad on your polisher. The abrasive product works with the pad to remove layers of paint so defects are leveled out and less noticeable.

- Polish: Polishes are the most common type of abrasive product for automotive paint correction. They typically offer a low to medium level of cut and are best used on light defects or for finishing after removing deeper defects with a compound. Because polishes are low aggression, they’re typically the first product you try when doing a test spot. Because factory paint is very thin, you always want to try the least aggressive process possible, like a polish and soft foam pad, before moving to compounds that remove more paint.

- AIO: AIO stands for “All-In-One”, meaning the abrasive product corrects the paint and leaves behind protection at the same time. AIOs are usually less aggressive than polish simply because we’re asking a single product to do three things: cut, polish and protect.

- Compound: Compounds are the most aggressive type of abrasive product for automotive paint. They utilize larger abrasive particles with a heavier cut to efficiently and effectively remove deeper scratches, swirls and other defects.

The Most Important Factor for Compounds: The Abrasive

The most IMPORTANT factor in paint correction is not the pad. It’s not the machine. And it’s definitely not the skill of the detailer.

No, the most important factor in paint correction is THE ABRASIVE.

Anyone who has ever been to one of my classes or read one of my articles on paint polishing knows that I ALWAYS stress the importance of using products formulated with GREAT abrasive technology.

Why?

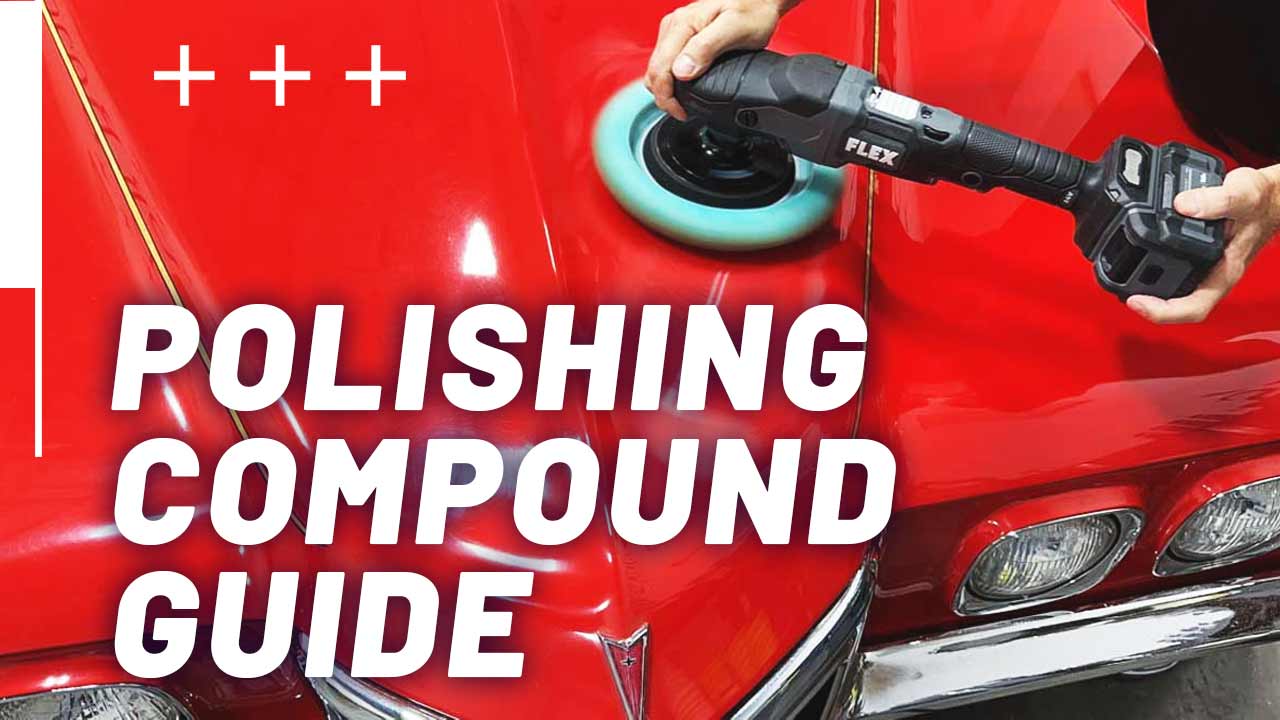

Look at the picture below and the story it tells.

In this photo you can see my long-time friend Jeff compounding the paint on a 1969 Ford Thunderbird, a barn find.

Analyze this image. What do you see IN ORDER of what touches the paint?

- The first thing you see “touching” the paint is the COMPOUND.

- Then, behind the compound is the buffing pad.

- Behind the buffing pad is the tool.

- Then, behind the tool, is the user.

This is all to say: skill is important, but skill is not touching the paint. The abrasive technology, the stuff in the bottle, that’s what’s touching the paint.

Based on this, I can say with confidence that in my experience, the most important factors in paint correction are in this order:

- Product

- Pad

- Tool

- Person

You may not like to hear that. A lot of detailers are a tick on the “alpha male” side and have an ego-driven approach to detailing because it was THEIR hard work that restored the vehicle’s appearance to a showcar finish.

Look, I get it. I’ve taken a lot of trashed out cars in my lifetime and restored them to better-than-factory-condition entirely by myself. There is a certain sense of pride and satisfaction that goes along with this type of restoration work. I’d even go as far to say that polishing is an art form.

After all, it is the human elements of care and passion that takes the craft of paint polishing and elevates it to an art form. We invest a PART of ourselves in EVERY car we detail.

THAT ALL BEING SAID… in my years teaching detailing classes, I’ve seen people with ZERO machine polishing experience, produce INCREDIBLE results with absolutely NO skill to draw from.

What they did have to draw from? Great abrasive technology.

So how do you know if abrasive technology is great? There are a few features you can look for while shopping that I’ll explain next.

What Makes a Compound Good?

There are a lot of different variables when it comes to compounds beyond personal preferences like brand, odor or scent.

When I’m considering a specific compound, there are eight or so characteristics I consider to determine how effective it is. They are as follows, from most to least important:

1. Removes Defects Without Leaving Defects Behind

Low quality abrasives are jagged and leave their own scratches behind during paint correction which need to be removed with a second polishing step. A good compound will feature high quality abrasives that are able to remove the defects without leaving too many scratches behind. In some cases, the abrasives may be so good you can even finish with the compounding step.

2. Long Buffing Cycle (A.K.A. “Play Time or Working Time”)

In order to remove the defects as much as possible, you need to be able to work the buffer for as long as possible over the surface. Therefore it’s important that the compound stay wet or liquid on the pad for as long as possible so the abrasives can continue to cut into the paint. If the compound dries up into the pad, it won’t be effective any longer.

3. Zero Dusting

Some compounds produce a great deal of dust during paint correction, requiring you to frequently wipe away residue and ensure any sensitive adjacent surfaces are masked against overspray. Compounds with low or no-dusting formulations speed up your paint correction process by eliminating the dusty mess, ensuring you can move from panel to panel with little-to-no interruption.

4. Fast Cutting/Abrading Ability

This one kind of speaks for itself. The best compounds remove defects quickly so you don’t need to work the product in one area for too long. This not only saves time, it makes it less likely you’ll burn through the clear coat during the paint correction process.

5. Easy Wipe-Off

Some compounds leave a tacky residue that requires a great deal of downward towel pressure to remove. This can induce micro-marring and overall slows down the paintwork correction process. The best formulated compounds are easy to wipe away to ensure minimal towel abrasion and efficient workflow.

6. Body Shop Safe — No Silicones

Silicone gets a bit of a bad rap in the detailing and body shop world. There are a lot of different types of silicone out there, and when used for the right product, they add slip to make wipe-off easier. The only time silicone is a problem is when you’re working in a fresh paint environment like a body shop (aka collision shop) where cars are being repainted. If any silicone becomes airborne and lands on a body panel before painting, the paint will form a bubble-looking defect due to the high surface tension created by the silicone. This defect is called a “fish eye”.

In a shop devoted only to detailing this is not as much of an issue. However, silicone can still act as a contaminant when applying a ceramic coating and will inhibit the bond if left on the paint before coating. For this reason, if you do use a compound that contains silicone, you should remove any residue with a panel wipe prior to ceramic coating.

7. No Fillers

Some compounds and polishes are formulated with fillers that fill-in and mask fine swirls and scratches to give the impression of a better final result. There are a few problems with fillers. For one, fillers degrade over time and the defects will re-appear. Two, fillers are technically contaminants in that they inhibit the ceramic coating bond. You need to remove them with a panel wipe like isopropyl alcohol before ceramic coating. On softer paints, this can mar the paint due to the lack of lubrication provided by the panel wipe. For these reasons it’s best to use a compound that contains zero fillers.

8. Pad Versatile – Compatible with Foam OR Fiber Pads

There are situations where fiber pads work best and situations where foam pads work best. The best compounds are compatible with both types to allow for the most versatility.

9. Tool Versatile – Compatible with Orbital, Rotary and Hand Polishing

When considering a compound you should look at the packaging or product page to see if it can only be used by machine or if it’s compatible with hand polishing. This is most important if you plan to polish the car’s paint by HAND, as there are very few compounds and polishes that are designed to be applied by hand. Modern clear coats are simply too hard to be effectively hand polished, so few manufacturers design for this application style.

What’s That Smell? Compounds and Petroleum Distillates

Some compounds you encounter will have a very foul odor. This is usually an indicator of V.O.C.s (Volatile Organic Compounds) still present in the formula. This occurs when the compound is formulated with some type of petroleum distillate or solvent and the ingredients aren’t filtered and refined extensively.

Because high quality, costly compounds sold by established brands use highly refined and filtered petroleum oils and solvents, they don’t have a foul odor. Therefore, you can sometimes tell if a compound is quality enough by whether or not it smells bad. That being said, this isn’t a hard fact, more of a general rule-of-thumb.

What’s the Best Polishing Compound for Cars in 2025?

I’m almost sad to say that I’ve been detailing cars and boats since the late 1970s. Since then I’ve worked for companies like Meguiar’s and 3D, who offer a range of their own compounds, and Autogeek, who resells compounds from hundreds of different brands.

In that time I have tried A LOT of compounds from A LOT of companies, including but not limited to:

- Adam’s

- Chemical Guys

- 303 Products

- Blackfire

- CarPro

- Collinite

- DP Detailing Products

- Griot’s Garage

- GTechniq

- GYEON

- Jescar

- Marine 31

- Menzerna

- Mothers

- Optimum – Been to the manufacturing plant in Tennessee!

- P&S

- Pinnacle Natural Brilliance

- RUPES – Been to the original RUPES manufacturing plant in Milan, Italy!

- SONAX – Been to the SONAX manufacturing plant in Newberg, Germany!

- Wolfgang

- Autoglym

- Gel Coat Labs

- IGL

- Kasse

- Koch-Chemie

- P21S

- Sonus

All of these brands make compounds that work pretty well.

At the end of the day, the only major problems I have with these brands’ compounds are in the carrying agents and abrasives they use.

All of these brands, as far as I know, use conventional petroleum distillates as their carrying agents. That means before you install a ceramic coating, you must first use a panel wipe (a solvent like isopropyl alcohol) to chemically strip the oils and any other by-products left behind. Otherwise the oils will contaminate the surface and prevent the ceramic coating from bonding. Ultimately removing oils slows down the paint correction process, and on softer paints, it can even scratch the freshly polished paint.

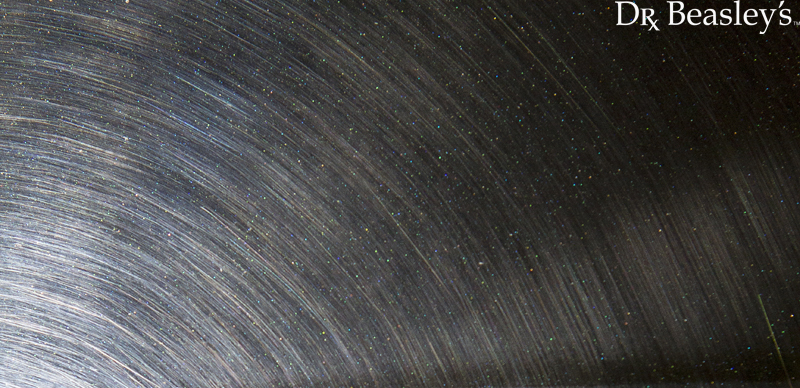

Then there’s the abrasive. When it comes to softer paints, the abrasives in a lot of these brands’ compounds will leave behind their own scratches, often called “micro-marring”, “DA haze” or “tick marks”. This is a common sign of a lower-quality abrasive.

What Compound(s) Do I Recommend?

There are so many different types of compounds it is impossible to make a one-size-fits-all recommendation.

Instead, I prefer to recommend specific brands, as their abrasive and carrier technology will generally apply to all the products in their line.

Below are two brands that I think are pretty good, and one brand that I think is head and shoulders above the rest.

Runner-Up Recommendation: Meguiar’s Pro Series Compounds

I worked for Meguiar’s for years as a trainer and copywriter. While I was there, Meguiar’s launched their “Pro Series” of compounds that featured a new abrasive technology called “SMAT”, or “Super Micro Abrasive Technology”:

- M105 Ultra-Cut Compound

- M100 Pro Speed Compound

- M110 Ultra Pro Speed Compound

SMAT is a high quality abrasive technology that doesn’t leave behind its own scratches to the degree that lower quality abrasives do. Meguiar’s “Pro Series” compounds are also free of the fillers present in Meguiar’s Ultimate Compound for the consumer market.

Overall Meguiar’s Pro Series compounds will deliver phenomenal results when used according to the directions. The only real downside with these compounds is that they still use the traditional organic, petroleum-based solvents and oils for carrying agents. That means you still need to remove them with a panel wipe like IPA, which as I explained, can scratch softer paints.

Runner-Up Recommendation: 3D ACA Compounds

3D is another brand I worked for over the years, and they’re unique in the industry for manufacturing their own abrasive technology. They developed a new technology called “ACA”, or “Alpha Ceramic Alumina” that cuts fast with a longer working time since they are not diminishing abrasives like 3D’s older technology AAT or “Adaptive Abrasive Technology”. The compounds in this line are as follows:

- ACA 500 X-Tra Cut Compound

- ACA 510 Premium Rubbing Compound

I generally have pretty good results with 3D compounds on medium to hard paints, but on softer paints they tend to leave their own micro-marring. The other downside is that like Meguiar’s, 3D uses traditional petroleum-based oils and solvents for carrying agents, requiring you to remove them with a panel wipe like IPA before applying a ceramic coating.

Top Recommendation: Dr. Beasley’s Nano Surface Primer CoreCut

Full disclosure: Dr. Beasley’s is the company I’m currently working for. But I wouldn’t be working for them if I hadn’t already fallen in love with their Nano Surface Primer line, which recently added two new compounds to its offerings:

These compounds both use high quality, faceted microsphere abrasives. This means you get a heavy cut with minimal micro-marring left behind. In fact, I’ve found CoreCut can even finish out as a one-step in some contexts.

CoreCut and CoreCut+ also have absolutely zero fillers, silicone or traditional petroleum-based solvents in their carrier. Instead, they utilize a unique “nanogel” carrier that’s totally inorganic and even helps lay a foundation for ceramic coating. That means you don’t need to do a panel wipe and your ceramic coating will form an ultra-durable bond to the already-primed surface.

While CoreCut is totally safe to use (with common sense) on the factory clearcoat you see on modern cars, I would caution against using CoreCut+ on conventional automotive paint. CoreCut+ is an ultra-aggressive compound that was designed for removing deep oxidation on severely neglected gelcoat boats. Gelcoat tends to be a lot thicker than car paint, factory or custom, so it needs a more aggressive compound to cut through and level deeper oxidation.

Overall, the NSP CoreCut is the compound I’d recommend most. Beyond eliminating fillers and petroleum-based solvents and the advanced microsphere abrasive, CoreCut is also dust-free, self-cooling and incredibly easy to wipe-off. It does everything I want a compound to do.

Final Thoughts…

There are a plethora of different brands for compounds and polishes on the market today. Some brands use very good abrasive technology, while others use mediocre abrasive technology. The visual difference in the final results are either flawless, swirl-free paint or paint with a hazy look in bright light due to micro-marring from the abrasive technology. Besides reading this article, do some research on any particular brand of compounds and/or polishes and see what other people are saying about their experience with these products.

The Internet is Your Friend

Nowadays, doing research on compounds and polishes is as easy as firing up a web browser, typing in a few key words and reading the results. Asking other enthusiasts as well as professional detailers for their experience and opinions can also be helpful but keep in mind, people are different and what works for one person may not work for another.

My Personal Offer to Help

I’ve been answering car detailing questions professionally since 2002 and moving forward, if after reading this article you have any questions about polishing and waxing, or how to use an AIO, my contact information is below, reach out to me, I’m always happy to help.

Would You Like to Learn How to Machine Polish Like a Pro?

- Would you like to take your detailing skills to a higher level?

- Do you find you learn better by doing versus sitting in a chair looking at a PowerPoint presentation about car detailing?

Here at Dr. Beasley’s O.R., (Operating Room), in sunny Stuart, Florida, we teach the most hands-on car and boat detailing classes on planet Earth. And we prove it too. You can find write-ups on the Dr. Beasley’s Blog that photo-documents just how hands-on our classes are plus you’ll see the kinds of cars and boats you’ll be training on.

Click the link below to find the dates, locations, topics, and prices for all upcoming detailing classes.

Upcoming Detailing Classes – Prices – Info – Topics – Locations

And if you ever have any questions, always feel free to reach out to me personally via text, phone call or email.

I hope to see you in a future detailing class!

Sincerely,

Mike Phillips

Chief Education Officer for Dr. Beasley’s

Mike@drbeasleys.com

760-515-0444

Dr. Beasley’s Contact Information

Questions via Email: MyTeam@DrBeasleys.com

Customer Care Hotline: 773-404-1600