We’re going to talk about holograms and swirls. And some people think they’re the same, but they’re kind of different. And I always tell people it’s important that we understand what the words mean so when we talk to one another, whether it’s online or in the real world, we really have a clear idea of what we’re saying.

What Are Swirls?

So, swirls are just random scratches. So, if you’ve got contaminants in your towel, contaminants in your wash mitt, contaminants in your drying towel, and as you’re wiping or washing or drying the towel, you randomly just put scratches in over time, this creates what we call swirls.

And what you do is when you look at the sun or a strong focal point of light, it looks like they’re in a circle, but they’re actually not. They’re random everywhere, but they’re all reflecting into that point of light. So they look like swirls or cobwebs or spiderwebs. So that’s what swirls are.

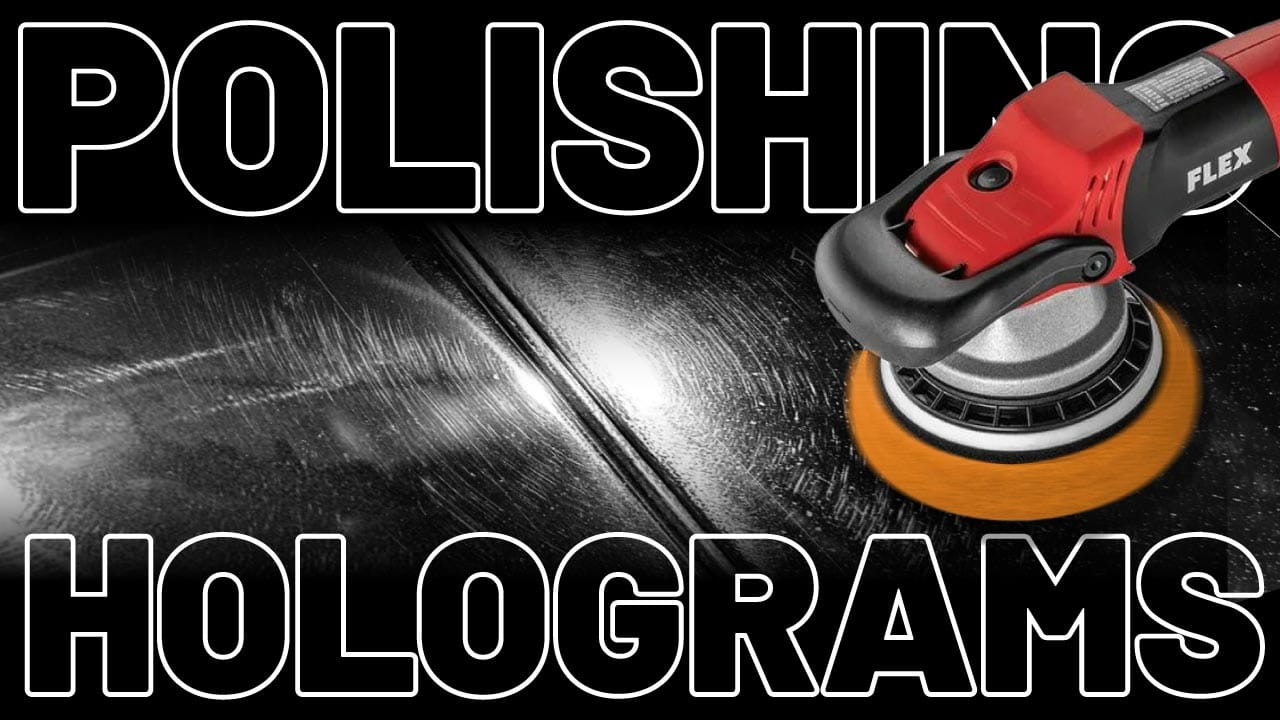

What Are Holograms?

Now, holograms are also scratches in the paint. But what makes them different than just random scratches or swirls is… They’re inflicted typically by the fibers and the compound of a wool pad. There you go. And then when you look at them, they leave a wispy or holographic or 3D-looking line besides the circular scratches that mimic the direction the pad or the buffer was moved over the paint.

So that’s how you can quickly tell if you’re looking at a car in the sun or with good inspection lights if the car has just swirls or swirls plus holograms. That means someone improperly buffed it with a wool pad and rotary.

The Proper Use of Wool Pads and Rotaries

Now, I want to make it very clear, I love wool pads and rotaries. They’re great to start with. Just don’t finish with them. And because when you do, you leave holograms in the paint.

Single-Stage Metallic Paints: What You Need to Know

So, the next thing I kind of wanted to talk about was, there’s two things. One, both of these cars, I’ve already done a little test spot on them. They’re both single-stage metallic.

Okay, so in my opinion, single-stage metallic paints would be called old school, so they’re probably solvent evaporation lacquers or enamels, probably enamels. They are the most difficult paint to restore when they go bad. And you’re going to see in a second why.

But the reason why is the flake in this is actually microscopic little pieces of real aluminum, metallic flake. Metallic means metal. Metal is the aluminum. It’s an aluminum flake finish. And just like aluminum, if you want to look at that slotted mag up there, just like the aluminum wheels on a car will oxidize, the aluminum flake in this paint will oxidize.

How Buffing Affects Single-Stage Metallic Paints

And so when you buff a single-stage metallic finish, instead of your pad turning the color of the pigment, it will turn the same color it would turn if you were polishing a slotted mag. And if you’ve ever done this before, polished, you know, uncoated aluminum, you start with a white cloth and say some mag wheel polish, both things are white, and you turn it over and it turns black.

So, my pad, instead of turning tan, or if I were to buff on this car, green, it’s going to turn black. And that’s the sign of a single-stage metallic paint.

The Risks of Buffing Metallic Paints

And over the course of time, each and every single little aluminum flake in this paint is sitting there, oxidizing. You come along and buff it, you pull the oxidation off, of course, you pull off some paint too, but you don’t see the color of the paint, you see the color of the oxidation.

And then what makes it even trickier is as you’re buffing, if you push too hard, use too aggressive of a compound, or basically just don’t know what you’re doing, you can leave a pattern in the paint that not only has holograms, but you’ve flipped the flake. You’ve left a pattern in the paint that mimics the way you move the polisher over the paint. And these are called tiger stripes. And this is pretty common to see in old single-stage metallic paints.

So, you don’t really do it with non-metallic paints, but you do it with metallic paints. Very, very tricky. I’d say it’s one of the hardest paints to work on, is a single-stage metallic paint.

Wet Sanding: The Challenge with Metallic Paints

And that’s another reason why they’re really risky to ever machine or hand wet sand or dry sand. It’s easy enough to sand. Remember, sanding is always putting scratches in. Anybody can do that. The tricky part is getting them out. And when you go to get them out, because now you’re trying to get sanding marks out, you’re pushing on that buffer, you risk putting in the tiger stripes. So it takes a lot of skill to work on something like this.

Examining Holograms and Scratches

And then let me talk about the holograms themselves. So, Yancy came over and picked up some of the holograms. They’re really prevalent on the hood, but they’re everywhere in the car, which means whoever buffed this out, they used the same tool, the same product over the entire car, and after that first initial step, they stopped.

But one of the things I noticed was the holograms are also very deep, okay? So you have two things that can put the hologram scratch in. You’ve got the fibers that make up a wool pad, but you also have the abrasive technology that is in your compounds, your polishes.

The Importance of Quality Abrasive Technology

So, I divide abrasive technology into two groups, and I don’t really like to use foul language on camera, but there’s great, and then there’s rap. And put a letter C in front of the word “rap,” okay? So there’s great stuff, and everything else is junk. There is no abrasive technology that’s kind of good, okay?

So here’s how this works. The good abrasive technology or great abrasive technology has the ability to remove a defect without leaving its own defect. All the junky stuff will remove defects, but it leaves its own defect behind. Now what are you going to do? You’ve got to come back and keep doing more steps to finally get the defects out that you’re putting in, trying to remove defects. It’s a catch-22 cycle.

Measuring Paint Thickness

Anyway, enough talking, Yancy. I did bring out a paint thickness gauge. Again, I don’t know. Let me turn it on. I don’t know what AMC paint was like back in the old days. There’s 7.8, 7.9. 7.9. If we go to this side, 8.2. So I did a bunch of testing. It’s in the range of a high six point to a low nine point. So it is kind of a uniform paint thickness gauge. It’s a uniform paint thickness throughout the entire finish.

Rotary Polisher: The Tool for the Job

So the first thing I want to do is I want to talk about your rotary polisher. This is the Flex PE150 cordless, my favorite rotary. Batteries last forever. A lot of power, all the power I’m going to need in order to do what I’m going to do here. And lightweight and quiet. It’s got stainless steel gears in here. That’s why it’s quiet. A lot of rotaries have stamped steel gears, and they growl when you buff with them. The most important thing, though, is to put your pad on so it’s completely centered.

Centering Your Pad

And one of the tips I like to share with people is I’ll spend 10, 15 minutes reapplying that pad to the backing plate and make sure it centers so it buffs smooth. And then once I get it so it’s centered, I’ll take an ink pen or a felt pen and spin it and then just kind of run the pen around the edge of the backing plate, which will mark it and match it to my backing plate on my tool. It makes it easier to put the pad on in the future. Oh, you’re so clever.

The Importance of Spur Cleaning the Pad

Okay, now, I know where this has been because I washed it and dried it and put it in my cupboard, but you should always spur a pad before you use it, just to make sure there’s not one little particle in there, because if there is, it’ll put what I call arc scratches. An arc scratch is like an arc. And you know, sometimes the things I share in these videos are things I’ve learned the hard way. I learned this the hard way— not cleaning your pad often. So all you gotta do is just run that spur.

And yes, it is like a little cowboy spur on the back of a boot of a cowboy. And what that’ll do is it’ll peel off any contaminants and kind of fluff up the pad and get it ready to start buffing with.

How Often to Clean the Pad

And how often do you do that while you’re working? Well, if you were to watch me buff out this car, and I am going to buff out this entire car, you would see me clean my pad usually after every section of a panel. I clean my pad often, a lot. And the reason why is a good question. Thanks for asking.

The reason why is cleaning the pad often does this: when you’re buffing with the wool pad in a compound or a polish, you’re removing paint, so that builds up on the face of the pad, but you also have the product you’re using, it becomes spent, and it builds up too. So you want to remove those two things. So just like if you think about it, if you buffed a section, you took a towel and wiped off that residue, you need to wipe off that residue, but you do it with a spur.

Why Cleaning the Pad Improves Buffing

And here’s the benefit to that. So now when you get ready to buff the next section or the next panel and you put down fresh product, you’re not diluting it or polluting it. So you’re buffing more efficiently, and the residue you leave behind isn’t as sticky, so it’s going to wipe off easier. That makes the job easier on you. If you don’t clean your pad, you keep gunking it up with fresh product and old product, the residue is going to wipe off more difficult. That tires you out, makes the job go longer.

Starting with NSP 150

Okay, now to do this, we’re going to start with the NSP 150. So currently— that’s a well-chosen word, currently—there is a strip of product. We have three NSP primers and we also have the Z1, which is an AIO. So in the old days, we called this a cleaner wax or a cleaner sealant, depends on what the protection ingredient was. But this will remove swirls and scratches and lay down a ceramic coating at the same time.

Two-Step Process with an AIO

And I’m pointing this out because a lot of people think I’m OCD, they’re so wrong. I’m actually lazy. And what I want to do is I want to cut, and if I can finish out with an AIO, it’ll work like a polish, but leave the car protected so I can do this in two steps. And that’s kind of what I’m all about, keeping my quality high, keeping my time investment low.

The 10 at 10 Technique

So the next thing I’m going to do is I’m going to pick up my product using the 10 at 10 technique. And basically what I’m gonna do is I’m gonna turn this polisher on. Okay, so it’s locked on. And you lay your pad down flat. And what you’re gonna do is you’re gonna tilt this up at about 10 degrees. And you want to look at this like it’s a clock. So here’s midnight. Midnight, one o’clock, two o’clock, three o’clock, so on. And you get over here to 10 o’clock. And what you’re gonna do is you’re gonna pick this up at 10 degrees and run that strip or what’s called a bead of product in at the 10.

And because this is spinning, as I look down on it, clockwise, it’s going to pick that strip and pull it into itself instead of throwing it all over Yancy and his camera lens. And if you’re good at that, it would look like this. Then once you pick it up, you spread it around, and then start working that panel.

The Pad Flat Controversy

Now, I know it’s controversial. A lot of people say you’re supposed to hold that pad flat. And look, I agree. That works good when your pad is fresh, clean, and dry. But as that pad becomes wet with product and a buildup of removed paint, what happens is that pad’s going to see the blackness. That’s single-stage metallic paint. You’d think it would be tan, because this is a tan-colored single-stage color.

But what happens is different portions of the pad will start to grab more than the other portions of the pad, and it yanks you around. And now you spend all your upper body strength, your leg muscles, your back muscles, trying to control this thing, all because you’re trying to hold it flat, because some guy told you to hold the pad flat.

Going Up on Edge

So what I teach in my classes is once you spread the product out, go up on edge. And it’s going to make controlling the buffer easier. So now you won’t get tired out because besides doing this little section here, I’ve got to do the whole car. I don’t want to get all tired out. So I want to work intelligently, work smarter instead of harder.

Correct Buffing Angle

Okay, now when you say “on edge,” obviously you don’t mean put it right on the edge of it. What’s the angle that you’re using? I’ll show you. So, like about like that. Now, look how easy this is to control. And I like to bring my cordless up to about the three, which is about 1,100 RPM. And it’s just so easy to use the tool now.

You know, Yancy, you’ve been working with me for, what, 12 years now? A long time. And nowadays, in all my classes, by 9 o’clock in the morning, I’ll have a rotary in your hand. We do not sit in chairs and look at a PowerPoint, and you listen to me talk and talk and talk. I take you out to the garage, show you how to use the tools, and put you to work on a car so you learn by doing. You’re working within the first five minutes of the class. It’s hands-on, there is no sitting, there’s no chairs.

Buffing with the Correct Technique

Anyway, so back to holding the pad at an angle. Now some people, and I get this, I cut my teeth calling on body shops in the 80s, so I get this, they’ll say, “Well Mike, if you go up on edge, you’re only using this part of the pad, and you’re gonna put deep swirls in because you’ve got more pressure on a smaller footprint.” Now that’s true if you’re using caveman compounds. But I’m not using caveman compounds.

And if you’re pushing really hard on the polish. Yeah, pushing hard and using a horrible pad. I mean, I got a junky pad in the cabinet here. I can show you what a junky pad looks like. This is a Lake Country pad. It’s a high-quality pad.

Working the Panel

So let me go ahead, and all I’m going to do for right now is I’m just going to buff out this rectangular area, and then we’ll go to the polishing step. So let me go ahead and work this. So what I’m trying to do is level the paint to remove those deeper holograms the other guy put in.

Now, besides the holograms, there’s also fish eyes, and there’s also all these thousands of straight-line scratches. And I did a little test spot on the roof earlier, which is the same type of paint. And what I found out was even though this is a single-stage paint job, the paint is actually really hard. And that means it’s more difficult to get all the deeper scratches out.

Rule of Thumb for Buffing

So I have kind of a rule of thumb, and I’m going to share it here. Look how long this product goes, OK? I’m going to share the rule of thumb. When I’m cutting hard with a wool pad like this and a compound— which NSP150 is kind of like a compound— and I make a standard eight section pass protocol over this section of paint, anything that comes out, that’s good. If it doesn’t come out, that’s because it’s deeper.

And at some point, if you want to get a good picture of that, you can even see it right here. That’s aluminum flake oxidizing in the paint. OK, so, you know, this is what I teach in my classes. Look, you know, I want to do my best. I aim for 100% defect removal. But I also have to balance out how much do I want to— how badly do I want to buy this guy a paint job when I actually got my own car I want to buy a paint job for?

Setting Expectations with Customers

So I tell my customers, and I say, “Look, I’m going to compound this. The shallow scratches are going to come out right away. The deeper ones are going to remain. If I start to chase them and I go through the clear coat— or in this case, I start to flip the flake— you’re not going to be happy.” So tell you what, let’s set our expectations. We’re going to make this car look so much better. It’s still going to have some problems. But they weren’t my fault; they’re the person that owned the car before you that put all these scratches in. And so keep things in context, you know.

Buffing Results

OK, I need a towel. Not everything has to be a show car on Pebble Beach.

What’s that now?

I said not everything has to be a show car on Pebble Beach.

Yeah. Well, like I said, this is going to look so much better. OK, so now, Yancy, I think if you come down and look, I don’t know if you can see any holograms, but you can see that from where I’m looking, all the holograms are gone. All the scratches and swirls are gone.

Dealing with Deeper Scratches

About the only thing that’s really left at this point are some deeper scratches. And I don’t know if you’re— there’s some right in here, and I could probably go and buff those out. But again, I made eight solid section passes, and I’m going to do that for the rest of the car, so if it doesn’t come out, it just tells me those deeper scratches are deeper, and maybe I don’t want to get in trouble and make a mistake.

Knowing When to Stop

A friend of mine once told me the difference between a professional and a hack is a professional knows when to stop. You know, the road to buying someone else a paint job is paved with good intentions.

Moving on to Z1

OK, so this is the Z1, and these come in these— this is a 32 fluid ounce package. And part of the reason for this is because most people are thinking they should get a 32-inch plastic bottle, but we have to keep this isolated from the air so the ceramic component doesn’t try to cure out. So it comes in a package like this, and it’s really easy to apply.

Since this is a new pad, I’m going to go ahead and just put a couple of dollops on there, because some of that’s going to actually go into the foam pad. I’ll take and spread this out. And this is, by the way, a foam polishing pad made also by Lake Country for the Dr. Beasley brand.

The Product Spreader

You know, wherever I go, I take my product spreader with me. That joke never gets old. OK, so there we’ve got some product on the pad. And this, of course, is the Flex 3401, 8-millimeter gear-driven beast. All brawl, no stall.

Applying the Product

OK, so first off, all I want to do is spread my product out. So here’s what I have here. I’ve got a uniform layer of abrasive technology and the nano gel technology. And look at the pad— already turning gray. That’s the metallic flake.

OK, so now I’m going to make my standard eight section pass protocol here. Something I haven’t taught for a couple of years, because we haven’t worked for a couple of years, is whenever you’re detailing, here’s a tip that will help you to speed up the process: Count your section passes out loud. I know it can sound silly, but here’s what the human brain does.

The Importance of Counting Section Passes

As I’m buffing up the car, not this section, but maybe an hour into it, maybe I’m down here in the lower fender, I’m starting to wonder, “Hmm, what’s for dinner tonight?” And then I forget what section pass I’m on. So I add a few more to make sure I did enough to match what my test spot was so the car will look good uniformly around the entire car.

But instead of guessing, just count your section passes out loud. You will cut about an hour of buffing time off of a detail job. And I’ve been teaching this for about five or six years now, and I have people that come to me all the time, like Mobile Tech Expo, and say, “Mike, I implemented that technique, and you’re right. Saves me time.” People do— they lose track.

Completing the Buffing Process

OK, so I’m going to do eight section passes, and I’m going to count them out. One. Five. Six. Seven. Less pressure. There’s eight solid section passes with metallic paint on the pad. You can definitely see the shine now.

Wiping Off the Residue

OK, wipe off. And here’s a tip: Anytime you’re working on your car, always look at your towels and feel them with your hands. A lot of times, your eyes may not see particles that are scratchy, but your hands will detect them. So I always tell people it takes hours to buff out a car. It only takes seconds to put a scratch in. That’s usually because your towels, your drying towels, your wash mitts, your wiping towels become contaminated over time. You’ve got to have a protocol in place to keep everything clean. Most people I meet don’t have a protocol.

No, they do not.

Inspecting the Final Results

OK, so there is a two-step process: compounding and polishing. And it’s done. But I’ve got some more information I want to share.

So here we go. Get back towards you.

This way?

Yeah, right there. OK. Now go across. Holograms, be gone. Keep going. Oh. There you go. Get back. They’re gone over the entire finish. And go. There you go. All right.

Wrapping Up the Process

OK, so that’s actually a really quick, simple, easy process. I mean, if you’ve never used a wool pad on a rotary, it’s always a good idea to practice on something that’s not important to you, like your wife or your girlfriend’s car. But it does cut faster. The key is always use great abrasive technology so the swirl that you leave behind is only from the fibers, and that means they’re shallow and the polishing step of the foam pad will pull them out really fast.

Maintaining the Finish

Now, when I finish this whole car, here’s something else I want to share because I like to keep things real simple. The guy that owns this, he’s a great guy, but he’s really not the kind of guy that would go out and prep the paint and put a ceramic coating on it. But here’s what he will do. He will take a product like Bead Hero— if I recommend this to him, and I will— and I can teach him how to maintain my hard work.

Teaching the Customer How to Maintain the Car

Basically, how to touch his car. So… put a spritz or two of the Bead Hero on there, take your towel, spread it around, flip to a dry side, and then wipe it off. And now he has a ceramic-coated finish that will repel water, keep the car cleaner longer, and create the same gloss and shine. And I know he can do it. It’s just that simple. So again, I like to try to keep detailing really simple, not complicated.

Conclusion: Restoring a Hologram-Inflicted Finish

I just restored a hologram-inflicted finish out with a two-step approach using quality products, quality tools, and quality pads. And I’m going to share with my customer how to preserve my hard work so his car looks good and I look good over time.