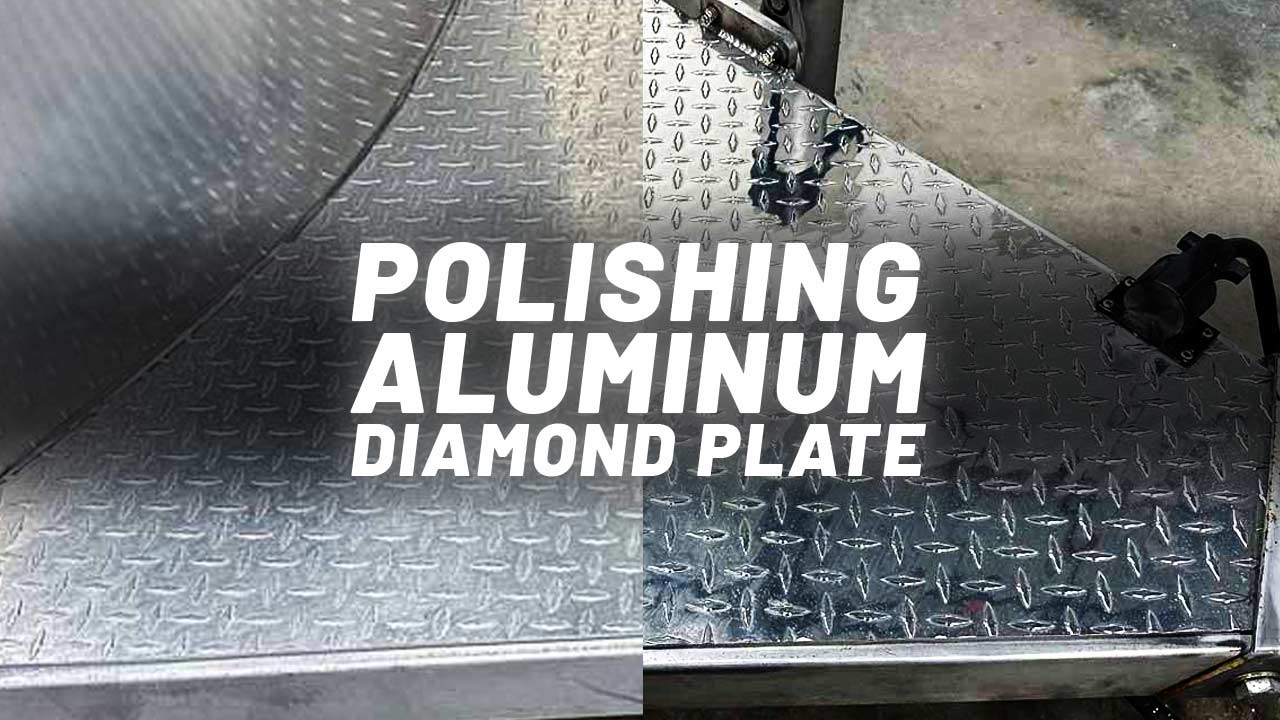

Aluminum diamond plate (also called tread plate or checker plate) is used on a variety of surfaces where durability, slip resistance, and corrosion resistance are needed such as stairs, walkways, or in this case, the top of the trailer hitch portion of an AeroVault car hauling trailer.

Like regular aluminum, aluminum diamond plate is typically shiny and reflective, if not a complete mirror finish. However, also like regular aluminum, it can lose its shine due to oxidation, dirt buildup, and surface scratches from wear or improper cleaning. Exposure to harsh chemicals, UV light, and moisture can also dull the surface, especially in marine or outdoor environments.

Thankfully, like regular aluminum, aluminum diamond plate can be restored to a brilliant shine easily with polishing. In this article, we’ll cover three different methods for polishing aluminum diamond plate:

- by hand

- with a polisher

- with a polishing ball drill attachment

How to Polish Aluminum Diamond Plate by Hand

Working by hand is the simplest way to remove oxidation and restore a brilliant shine on diamond plate aluminum. This approach will require some old-fashioned elbow grease as well as a few old terrycloth towels and worn-out t-shirts plus a great aluminum polish.

- Aluminum polish

- Nitrile gloves

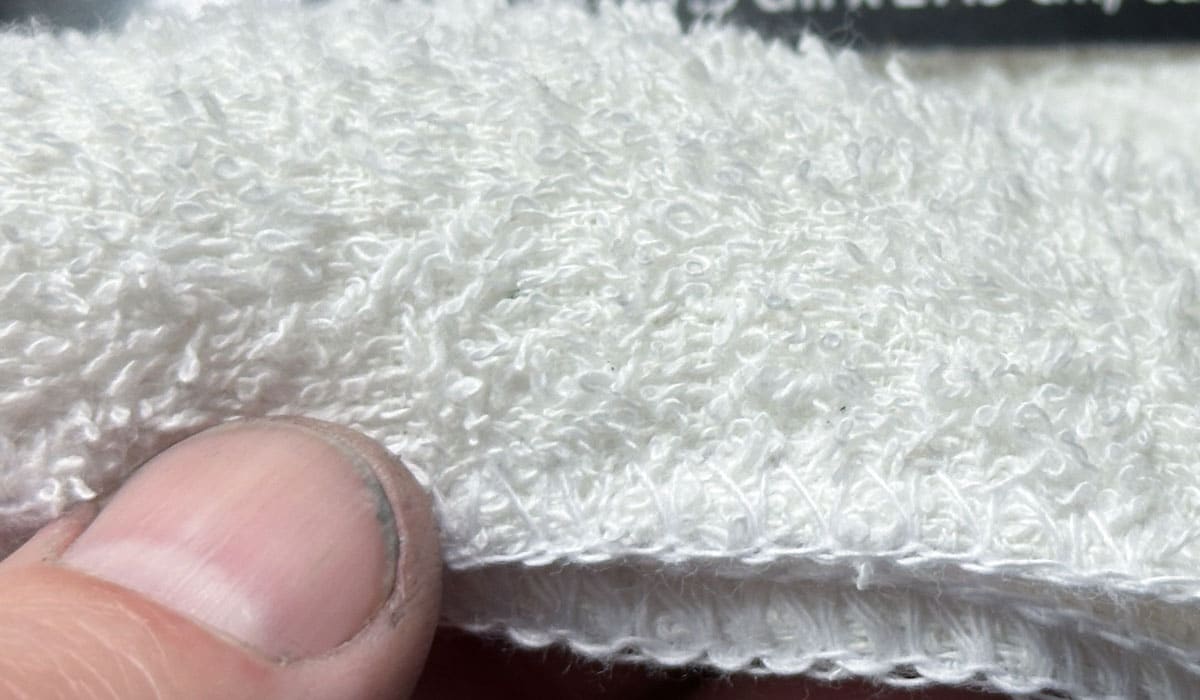

- Terry cloth towels – cut into smaller sections about 6” x 6” square

- Old t-shirts – cut into smaller sections about 6” x 6” square

- Metal Ceramic Coating

- Foam or microfiber applicator pads

- Optional: Make-up removal cotton rounds

- Optional: Corn Starch

The process is pretty straightforward, you’re going to choose the type of material to start with based upon the current condition of the aluminum diamond plate.

For Heavy Oxidation & Neglect: Rub with Terry Cloth

For severely neglected aluminum diamond plate with lots of dull oxidation, you’ll remove the oxidation faster and easier if you start with terry cloth as your rubbing cloth. The tiny loops of cotton string known as the nap provides a little more cleaning and abrading action working together with the abrasives in the metal polish.

Compared to the flat weave of a cotton t-shirt, terrycloth is a lot more aggressive. But note that due to this more aggressive nature of terrycloth, you may need to do a second and even third polishing step and for these steps, simply repolish using a softer material like cotton t-shirt.

For Light Oxidation & Neglect: Rub with Old T-Shirt Cloth

For light oxidation, you can often times start with the less aggressive, flat weave surface of sections of cloth cut out of an old t-shirt. Old t-shirts have normally been worn and the washed and dried hundreds of times and this tends to make the feel and touch of the cotton surface soft and gentle when polishing and abrading oxidized aluminum diamond plate.

Step-by-Step Instructions for Polishing Aluminum Diamond Plate by Hand

For this demonstration I will be polishing the diamond plate aluminum sheeting on the top of the trailer hitch portion of an AeroVault car hauling trailer. The entire trailer, including this chunk of diamond plate, is severely neglected, and oxidized.

Take note that this section of diamond plate is dull and oxidized.

Here’s a close-up shot of the area I will polish by hand.

- Wash and dry aluminum diamond plate to remove any loose dirt.

- Shake the metal polish well and apply directly onto the appropriate cloth material based upon the condition of the aluminum diamond plate. In this example, I have a cotton terry cloth round applicator pad.

- Rub the polish and the cloth in a back-and-forth motion over a section of aluminum diamond plate. If you can see a visible grain in the aluminum diamond plate, be sure to rub back-and-forth in the direction of the grain.

After rubbing hard for about a minute, you can see the amount of oxidation I’m removing from just a small area. - After a minute or so of fast rubbing with strong pressure, wipe off the results and inspect.

Pro-Tip: Sprinkle cornstarch on your towel to make residue removal easier.

If you look closely, you can see that with just a little hand polishing, I have removed the oxidation and restored a pretty good shine to this one small section of diamond plate.

If the results meet your expectations, move onto a new section and be sure to overlap a little into the previously worked section for an overall uniform appearance.

If the results do not meet your expectations, you can try working a new section only for this section, switch over to a more aggressive cloth or polish or both. At some point, you should be able to dial-in a process that removes the oxidation to your expectations while creating a brilliant, chrome-like shine.

If you are unable to dial-in a process to remove the oxidation and restore a factory-new appearance, it’s likely the only way to proceed will be to work by machine.

How to Get a Mirror Finish on Aluminum Diamond Plate by Hand

Here’s a professional detailer’s secret to a showcar shine on aluminum diamond plate. The secret is to do a final polishing step using cotton rounds.

Cotton Rounds are usually circular-shaped patches of super soft cotton that people use to remove cosmetic make-up off their face at the end of the day.

The reason cotton rounds can finish out nicer than old t-shirt cotton cloth is because it has no weave pattern. As soft as an old t-shirt can be, it still has a crosshatch weave pattern to the surface. This light crosshatch weave pattern is what enables t-shirt material to provide some gentle abrading action to remove oxidation. But this same crosshatch weave pattern simply is not as soft as cotton round. A cotton round has no weave pattern, it’s just soft, fluffy cotton.

When trying to take the aluminum polishing results to the highest level, you need every aspect of the polishing process working for you and this means doing a dedicated final hand polishing step using a premium quality aluminum polish with a common but intrinsic addition to the process, mundane, ordinary cotton rounds.

- Apply a small amount of polish onto a cotton round.

- Spread the product over a small section of aluminum diamond plate.

- Gently rub the cotton round in a back-and-forth motion in the direction of any present or visible grain.

- If the aluminum is completely smooth, then rub in back-and-forth movements in a manner that best works for the shape and size of the section being polished.

- Remove any excess polish using your best microfiber towels.

Here’s the results after a second polishing step using the same product and technique, the one thing that has changed is the applicator material – a round, cotton make-up remover.

The results are night and day. But appearances can be deceiving.

Here’s the same section with a strong hand-held light shining on the polished section. You can see swirls and scratches in the flat aluminum areas, and these are fairly good results knowing how bad the aluminum was to start with.

How to Polish Aluminum Diamond Plate by Machine

While aluminum diamond plate can be polished by hand, polishing by machine is much faster, more efficient and easier on your arms.

For this demonstration, I’ll be showing a multiple step machine polishing process that’s fast and efficient and includes starting with a wool cutting pad on a rotary polisher.

Full Supply List for Polishing Aluminum Diamond Plate by Machine

- Rotary polisher

- Rotary extension shafts

- 6” and 3” rotary backing plate

- 7.5” and 3.5” Wool cutting pads

- 6” and 3.5” Foam polishing pads

- Nitrile gloves

- Terry cloth and/or microfiber towels for wiping off metal polish residue

- Metal Coat for protection

- Foam or microfiber applicator pads

- Safety glasses

- Optional: Leather work gloves

- Optional: Make-up removal cotton rounds

- Optional: Corn Starch

- Wash and dry aluminum to remove any loose dirt.

- Attach wool or foam buffing pad to rotary polisher matching the size of the pad to the backing plate. If using a small buffing pad to polish hard to work areas, attach a rotary extension shaft to the rotary polisher spindle first, and then attach the correct size backing plate.

- For extremely oxidized metal start with the wool buffing pad and re-polish with a foam buffing pad. For light oxidation start with a foam pad.

- Fingerpaint some polish onto the section of aluminum to be polished or place a strip of product onto the surface. Press the buffing pad against the polish and bring the rotary polisher up to a slow speed and spread the product over the section to be polished.

- Bring the rotary up to a medium speed setting and begin moving the spinning buffing pad over the aluminum in a smooth, controlled pattern. If there is a grain to the aluminum, move the spinning buffing pad so that it is moving over the aluminum in the direction of the grain. If the aluminum is smooth, without any visible grain, then it doesn’t matter which direction you move the spinning buffing pad. Buff a section of aluminum for about a minute or so.

- Remove the metal polish residue and inspect. (Use the cornstarch technique to make removing easier!) If the results meet your expectations, move onto a new section and be sure to overlap a little into the previously worked section for an overall uniform appearance.

- If the results do not meet your expectations — for example this process is not removing heavy oxidation fast enough or effectively enough — you can try working a new section with a more aggressive buffing pad or polish or both.

- If the results look good but you see pad marring, then switch over to a foam buffing pad and re-polish to remove any marring.

At some point, you should be able to dial-in a process that removes the oxidation to your expectations while creating a brilliant, chrome-like shine.

How to Remove Holograms From Aluminum Diamond Plate

If you used a fiber wool pad, there will be cuts or scratches in the aluminum diamond plate and this scratch pattern is called holograms. To remove any holograms left by a rotary polisher, you’ll need to re-polish using a foam polishing or foam finishing pad, a quality metal polish and a random orbital polisher.

Which foam pad will work best and whether a third polishing step is needed depends upon how deep the holograms are from the first step. You’ll need to do some testing to dial-in a process that meets your expectations.

As an option, you can re-polish using a foam cutting pad on a rotary, followed by a foam polishing pad on an orbital. How perfect you want to get the aluminum diamond plate is up to you, but simply put, more steps tends to mean better results.

How to Polish Aluminum Diamond Plate by Polishing Ball Drill Attachment

There are a lot of great options out there for polishing aluminum diamond plate by machine than just polishers. Metal polishing ball attachments for power drills are one example.

The way these work is you attach the metal polishing ball to a common household drill, either corded or cordless. Next you apply some metal polish to either a section of the aluminum by fingerpainting the polish onto the surface or apply a small amount of polish directly to the surface of the metal polishing ball.

Next, with a firm grip on the drill, press the metal polishing ball against a section of aluminum and slowly bring up the speed of the drill to spread the polish around and then start polishing.

What’s Better for Diamond Plate Aluminum — Foam or Fiber Polishing Balls?

Metal polishing balls come in both foam versions and fiber versions.

Foam Polishing Balls: Because the foam is softer and more gentle than fiber or cloth versions, can and will leave a nicer looking finish. On the flipside of this coin, because foam tends to be softer and more gentle, they may not offer enough abrading or polishing-action to remove heavy oxidation.

Cloth Polishing Balls: Cloth polishing balls are better for restoring aluminum surfaces with heavy oxidation, but the flipside of this coin is, because the cloth offers more abrading ability, or polishing ability, the cloth itself can leave light marring.

If you plan on doing a multiple step process when polishing neglected, oxidized aluminum, by incorporating a second or third polishing step like shared in the section above for working by hand, then you can start with a cloth metal polishing ball and then come back and re-polish using a foam metal polishing ball.

If you’re wanting to create Concours, show quality results when working by machine, the thing is you normally cannot beat the results created by fine hand polishing using soft cotton rounds.

Simply put, there are some things in life that are best done by going old-school and finishing out by hand.

How to Polish Aluminum Diamond Plate with a Foam Metal Polishing Ball

Supplies Needed

- Foam Metal Polishing Balls

- Drill – corded or cordless

- Aluminum polish

- Nitrile gloves

- Terry cloth and/or microfiber towels for wiping off metal polish residue

- Metal Sealant

- Foam or microfiber applicator pads

- Optional: Make-up removal cotton rounds

Here’s the correct order of steps:

- Wash and dry aluminum to remove any loose dirt.

- Attach the metal polishing ball to the surface to be polished or onto the outside of the foam ball.

- Apply some metal polish to the outside of the metal polishing ball or directly onto the surface to be polished.

- Press the metal polishing ball against the metal surface and bring up the speed of the drill slowly so as to prevent throwing splatter.

- Spread the product around to the area to be polished and then press the spinning metal polishing ball against the metal surface for a minute or so.

- Remove the metal polish residue and inspect. If the results meet your expectations, move onto a new section and be sure to overlap a little into the previously worked section for an overall uniform appearance.

If the results do not meet your expectations, you can try working a new section only for this section, switch over to a more aggressive cloth or polish or both. At some point, you should be able to dial-in a process that removes the oxidation to your expectations while creating a brilliant, chrome-like shine.

Because this is a flat, horizontal surface, it’s just as easy to pour a little metal polish onto the diamond plate aluminum.

For this article, I’m using the FLEX 24 Volt Cordless Drill.

Bring the foam metal polishing ball up to the polish hand using slow speed, gather the polish onto the foam polishing ball.

Machine polish the aluminum and attack the diamond plate grid surface from multiple angles.

Using some corn starch and a cotton terry cloth towel, remove the polish residue and inspect.

Here’s a close-up for the section polished using a foam polishing ball. When compared to the section polished by hand you can easily see the machine powered foam ball was dramatically better at both bringing up a brilliant shine and also removing a lot of the swirls and scratches that were in the aluminum.

How to Polish Aluminum Diamond Plate with a Cloth Metal Polishing Ball

Supplies needed

- Cloth Metal Polishing Ball

- Drill – corded or cordless

- Aluminum polish

- Nitrile gloves

- Terry cloth and/or microfiber towels for wiping off metal polish residue

- Metal Sealant

- Foam or microfiber applicator pads

- Optional: Make-up removal cotton rounds

Here’s the correct order of steps,

- Wash and dry aluminum to remove any loose dirt.

- Attach the cloth metal polishing ball to drill.

- Apply some metal polish directly onto the surface to be polished or to the outside of the metal polishing ball.

- Press the metal polishing ball against the flannel metal surface and bring up the speed of the drill slowly so as to prevent throwing splatter.

- Spread the product around to the area to be polished and then press the spinning metal polishing ball against the metal surface for a minute or so.

- Remove the metal polish residue and inspect. If the results meet your expectations, move onto a new section and be sure to overlap a little into the previously worked section for an overall uniform appearance.

If the results do not meet your expectations, you can try working a new section only for this section, switch over to a more aggressive cloth or polish or both. At some point, you should be able to dial-in a process that removes the oxidation to your expectations while creating a brilliant, chrome-like shine.

For this demo, we’re using the Flitz 5” Buff Ball with the White Diamond Metal Polish.

Pour a little metal polish onto the diamond plate surface then bring the cloth metal polishing ball up to the polish using slow speed, gather the polish onto the polishing ball and begin removing oxidation.

In the same way you want to attack the diamond plate grid surface from multiple angles when using a foam metal polishing ball you want to do the same using the cloth metal polishing ball.

The cloth make-up for this Flitz Buff Ball is that the cloth is a lot more durable than the foam, and this means you can really lean-into the drill to press the spinning cloth ball into all the various grooves and crevices that make-up the diamond plate design, which can be more difficult to polish versus flat surface aluminum.

Sprinkle some corn starch directly on top of the polish residue.

Using cotton terry cloth towels, remove the cornstarch and thus remove the polish residue.

Here’s the final results, an almost chrome-like reflection.

You can even see the reflection of my camera case in the below picture. Before we started, there was ZERO reflection coming out of the oxidized aluminum diamond plate.

How to Protect Aluminum Diamond Plate with Ceramic Coating

After you finish polishing the diamond plate aluminum, it’s a good idea to protect the newly restored surface with a ceramic coating designed to bond with metal surfaces.

Here are step-by-step instructions for protecting polished aluminum with a ceramic coating:

- Use a panel prep to chemically strip the surface to remove any residual polishing oils or solvents. Or in this example, to remove the built-in sealant in the White Diamond Metal Polish formula.

- Apply some of the Dr. Beasley’s Metal Coat or your choice of metal sealant onto a clean, foam or microfiber applicator pad.

- Apply over a small section of metal surface at a time. Spread and massage the product over the surface, working the product into the pores and grain of the aluminum to leave a thin, uniform layer of product.

- Remove using a clean, dry microfiber towel.

- Move onto the next section and repeat.

Here’s the results after sealing the surface with Metal Coat.

There you have it — three different techniques for polishing diamond plate aluminum to restore a brilliant shine.

If I had to pick my favorite, it’d probably be polishing by machine using a multi-step process. It’s the fastest, most efficient and produces the best results out of the three techniques I demonstrated.

This guide focuses on how to polish aluminum diamond plate. I’ve also got articles on how to polish aluminum by machine and how to polish aluminum by hand.

My Personal Offer to Help

I’ve been answering car detailing questions professionally since 2002 and moving forward, if after reading this article you have any questions about polishing and waxing, or how to use an AIO, my contact information is below, reach out to me, I’m always happy to help.

Would You Like to Learn How to Machine Polish Like a Pro?

Would you like to take your detailing skills to a higher level?

Do you find you learn better by doing versus sitting in a chair looking at a PowerPoint presentation about car detailing?

Here at Dr. Beasley’s O.R., (Operating Room), in sunny Stuart, Florida, we teach the most hands-on car and boat detailing classes on planet Earth. And we prove it too. You can find write-ups on the Dr. Beasley’s Blog that photo-documents just how hands-on our classes are plus you’ll see the kinds of cars and boats you’ll be training on.

Click the link below to find the dates, locations, topics, and prices for all upcoming detailing classes.

Upcoming Detailing Classes – Prices – Info – Topics – Locations

And if you ever have any questions, always feel free to reach out to me personally via text, phone call or email.

I hope to see you in a future detailing class!

Sincerely,

Mike Phillips

Chief Education Officer for Dr. Beasley’s

Mike@drbeasleys.com

760-515-0444

Questions? Comments?

Email Us