Last Updated April 29, 2022

As we said in our last article, car polish tech is stuck in the age of wax, but that’s all about to change with a new technology called DxPrime. Developed by Dr. Beasley’s for their new “Nano Surface Primer” line, DxPrime does what most polishes can’t: correct paint WHILE prepping for ceramic nanocoating application. See, up until now, virtually all polishes were designed solely to prep for wax (or sealant) application. They were loaded with oils, silicones and waxes intended to improve the shine and lay down a wax base. That made complete sense—for the time. But when ceramic nanocoatings hit the scene, all those additives started posing a problem.

Unlike waxes, which simply lay on top the paint, ceramic nanocoatings actually form a crosslinked bond with it. For this bond to take hold, you need a purified, stable surface, and those organic fillers actually work to destabilize. Unstable surface leads to a bad bond, and suddenly you’re stuck with a coating that won’t last very long at all. To get around this, detailers use isopropyl alcohol and other chemicals to wipe away the impurities, but even then a totally pure surface is never guaranteed. At the end of the day, polishes and coatings are just plain incompatible, and only through quick fixes and workarounds have we been able to make them jive together.

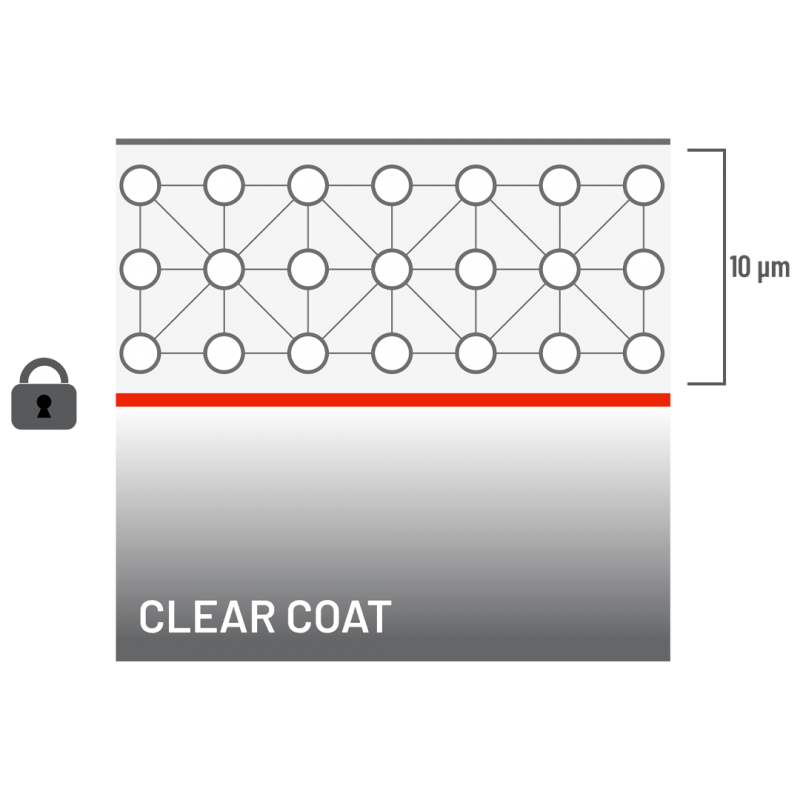

Seeing this incompatibility, Dr. Beasley’s Jim Lafeber got in the lab and came out with a correction technology that actually works with coatings, enhancing them instead of working against them. He called this technology DxPrime, and the Nano Surface Primers (NSP) were the end result. See, DxPrime is doing two things when buffer hits paint. One, the microsphere abrasives precisely correct the surface, removing imperfections. Two, the nanogel base protects the newly perfected surface with a ceramic nanocoating base, optimizing the coating bond and adding thickness.

So how does this all work? Let’s break down each aspect of the technology and get to the heart of what makes the Nano Surface Primers the solution to all our polishing problems.

Nanogel: Cut & Cover

The nanogel that makes up the “base” of the Nano Surface Primers holds the abrasives in place so they distribute evenly and therefore cut evenly. Traditional polishes will use a cream as the base instead of a gel, so abrasives tend to sink to the bottom of the bottle and accumulate. Not great for cutting precision.

But what really makes the nanogel unique is that it’s not just a base—it’s also a ceramic nanocoating primer. Hence the term “Nano Surface Primer”. So while the abrasives are correcting imperfections, the nanogel is protecting the restored surface with a ceramic nanocoating base. This has several benefits that make Nano Surface Primers a better choice for coating surface prep than standard polish.

One, it cuts out organic residuals so you don’t need to take up time removing them to get a decent coating bond. Two, it protects the surface from scratches and contaminants before the coating is applied. Three, it adds a layer of thickness to the soon-to-be-applied coating, providing more durability. Finally (and most importantly) it drastically improves the surface bond by laying down an adhesion matrix that firmly crosslinks with the coating.

Microsphere Abrasives & The Science of Smooth

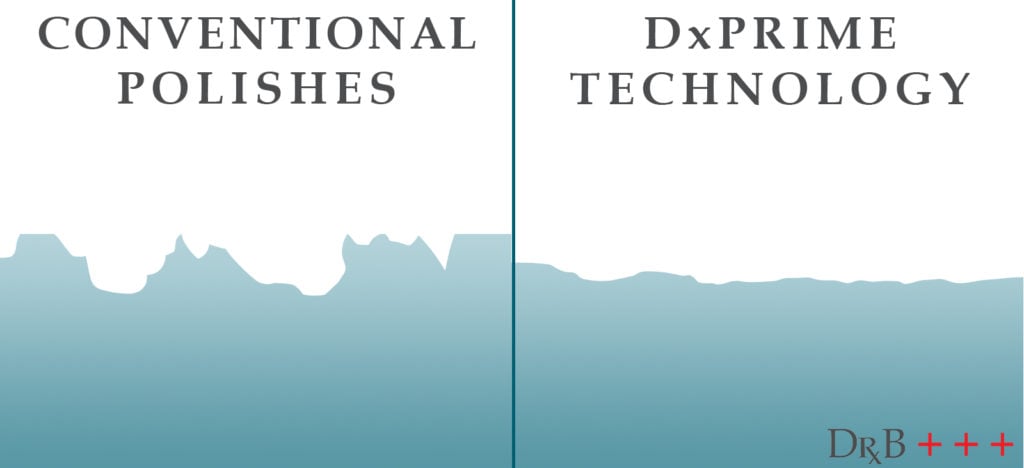

There are a lot of abrasive technologies out there, and we went over the most ubiquitous ones in our last article. The DxPrime technology uses a kind of abrasive called MSAT (Microsphere Abrasive Technology), or microspheres. Microspheres are engineered to be uniformly round, with each tiny bead precisely cut to match a certain size. Put these head to head with the more irregular-shaped super micro abrasive technology (SMAT) and MSAT will always come out on top when it comes to a smoother paint surface.

That’s part of the reason why outdated polishes use all these waxes and fillers—they fill in the imperfections these subpar abrasives leave behind, providing that beautiful shine you’d expect from a polish. But this shine is short lived; organic fillers like wax break down over time. Only microsphere abrasives truly harness the science of smooth, delivering the highest level of shine before the coating is applied.

Optimizing Coating Workflow

Professional detailers value efficiency. They respect their time and their customer’s. And yet when detailers perform ceramic nanocoating services, they waste time removing all the organic fillers left by dated polish technology. The key to a more efficient coating workflow is in eliminating this step, and DxPrime technology does just that with the Nano Surface Primer line.

As we’ve said before, most polishes are going to leave behind organic residues and oils that you have to wipe up before coating. That takes time, effort, and can also mess up your hard correction work, since wiping is abrasive and can inflict scratches. Then it’ll take even more time to go back and do a second pass. DxPrime cuts out the need for this inefficient extra step by eliminating organic residuals entirely, replacing them with a nanogel that instantly protects your work. No need to waste time wiping away impurities, and definitely no need to go back and polish out new scratches. DxPrime technology optimizes coating workflow in a way we’ve never seen before.

It’s Not a Polish—It’s a Primer

The Nano Surface Primers that DxPrime makes possible aren’t polishes—they’re primers. They go beyond just correcting the surface. They actively stabilize, optimize and lay the foundation for a protective coating with clear coat correction as just one aspect of that process. That’s why they’re Nano Surface Primers, not nano surface polishes.

With the NSP line available soon, conventional polishes will be left behind with wax and other dated tech. They were good at the time, but the future is here and the benefits are unbeatable. Now, as with any new technology, there’s a lot to talk about, so we’ll be releasing new articles regularly on how DxPrime and the NSPs work.

Questions? Comments?

Email Us