Last Updated April 4, 2025

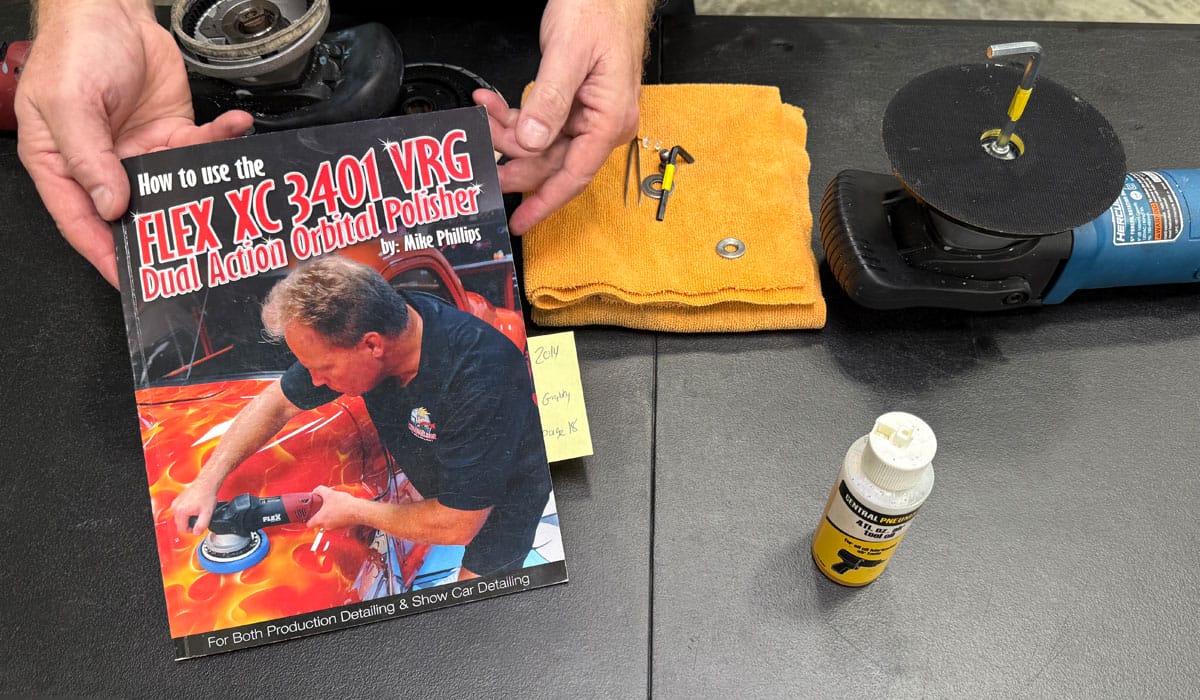

The Harbor Freight Hercules Forced Rotation DA Polisher is an almost exact copy of the Flex XC 3401 VRG Dual Action Polisher, AKA the BEAST — all the way down to the felt ring that lines the inside of the aluminum housing behind the backing plate. I noted this when I first reviewed the Hercules Forced Rotation DA, which you can read and watch here.

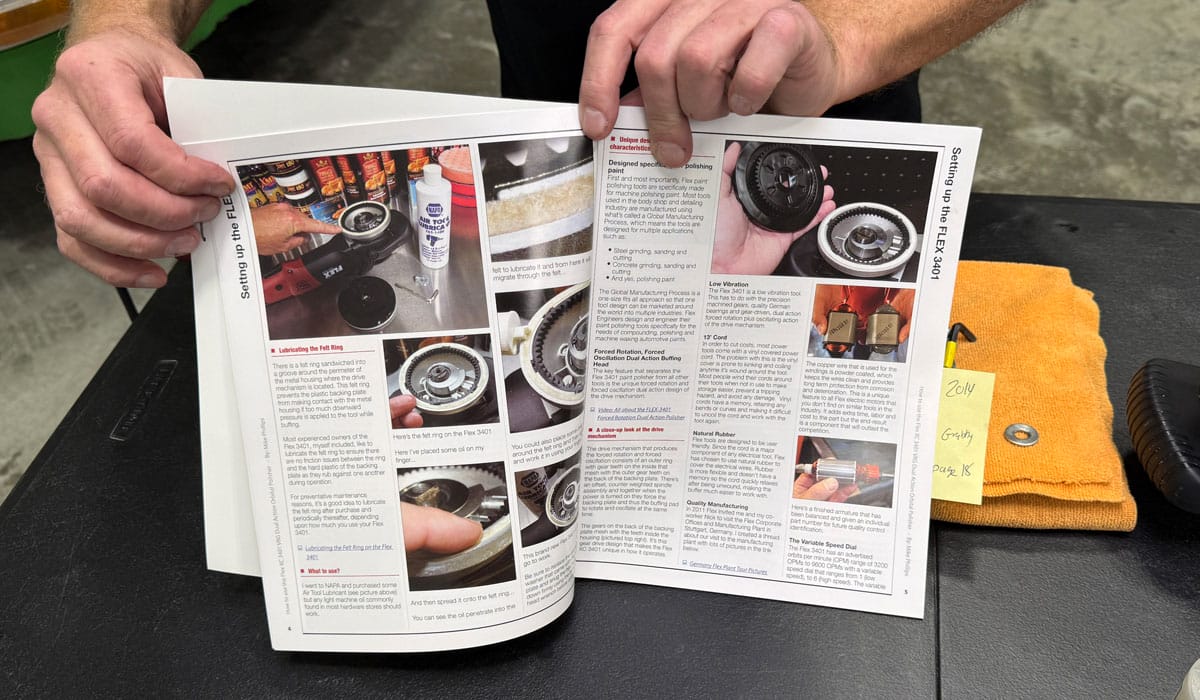

Back in 2011 when I wrote the official guide to the Flex BEAST, I included a section on how to lubricate that felt ring to avoid friction between the hard plastic back side of the backing plate against the rough texture of the aluminum housing. A few drops of oil will ensure the backing plate slips instead of grinds against the aluminum housing anytime you’re pushing hard on the head of the polisher.

With the Harbor Freight Hercules Forced Rotation DA Polisher being such a popular tool due to its low price, I thought it would be helpful to re-create this guide to lubricating the felt ring. In this article, I’ll explain why I recommend lubricating the felt ring on the Hercules Forced Rotation DA, how to remove the backing plate safely, how to lubricate the felt ring and/or flip it to a new side and of course how to correctly re-assemble the tool.

Why Should You Lubricate the Felt Ring on the Harbor Freight Forced Rotation DA Polisher?

When I first wrote this guide for the Flex XC 3401 VRG, I asked Flex Power Tools about lubricating the felt ring. They said there was no reason to lubricate the felt ring, and while I respect their take on the topic as the creators of this tool, I don’t think their marketing and engineering teams could anticipate someone pushing this tool to its limits like I do.

Like I mentioned above, the reason why I like to lubricate the felt ring is because I push hard when I’m polishing with a gear-driven tool. These types of polishers don’t stop spinning when you press them hard against the paint surface like free-spinning DAs do, and pressing harder against the paint makes the abrasives cut more. Thus you’re able to remove deep swirls and scratches much faster. I like working fast, so I press hard.

Here’s an analogy to help you wrap your brain around abrading paint. Think of how you use an ice cream scoop to scoop ice cream out of a container. You press the ice cream scoop hard into the frozen ice cream and you’re able to scoop out a fairly nice chunk of ice cream. It’s the same for car paint: the harder you press, the more you get out.

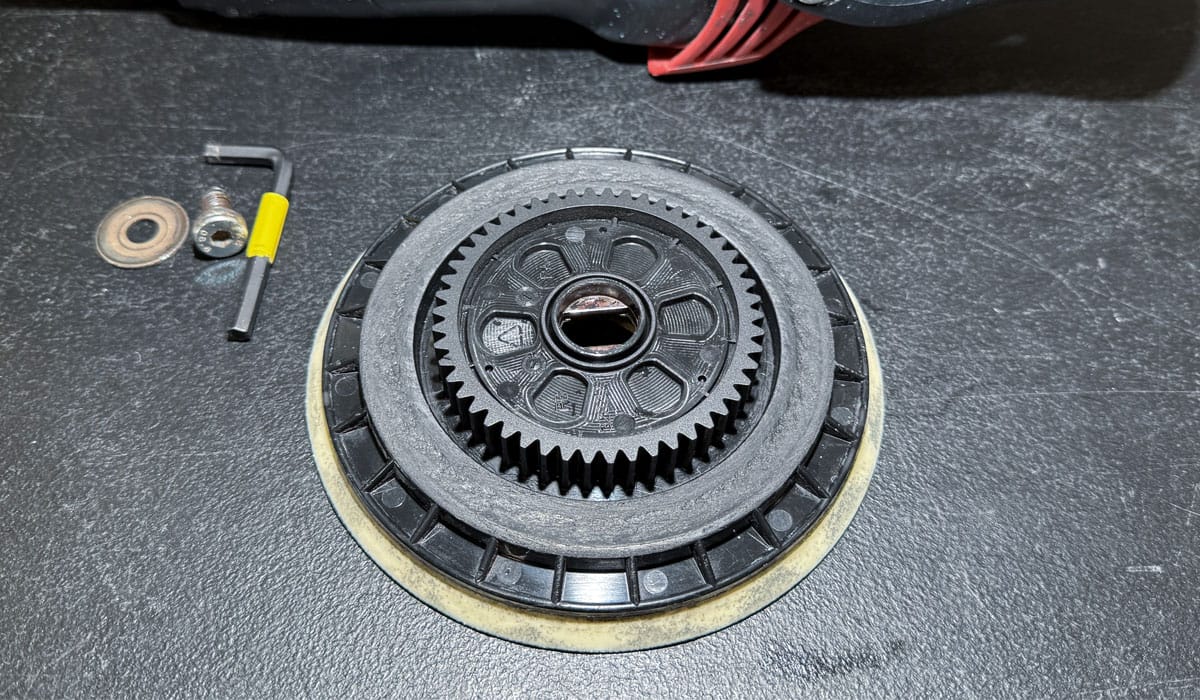

Here’s where the felt ring comes into play. Pressing this tool hard against the paint for long periods of time makes the hard plastic backing plate flex. When the backing plate flexes, it will come into contact with the aluminum housing and without the lubrication, the aluminum housing will grind small pieces of black plastic off the backing plate and these shards of plastic will fly out onto the paint where you’re buffing.

Now you have to stop buffing and carefully remove the hard, tiny shards of plastic before they get trapped under the spinning buffing pad, scarring the paint. It’s dangerous and it wastes time. All of this is to say if you’re going to be pressing hard on the paint with a gear-driven polisher on a regular basis, you need to lubricate the felt ring.

To visually illustrate this problem, check out the photos below.

This is a Flex XC 3401 VRG I used for a live demonstration. There was no lubrication on the felt ring and when I pressed down hard to demonstrate the capabilities of the tool, the pressure against the head of the polisher caused the backing plate to flex, grinding the outer lip of the aluminum housing into the plastic. Tiny pieces of black plastic from the backing plate flew out of the housing all over the paint. It was not a good look for me when demonstrating this tool. Safe to say I learned my lesson.

Here’s another example: once while buffing out an extremely neglected Mustang I pressed down particularly hard (I was trying to do a 1-step approach) and the aluminum housing actually CUT off a perfectly round chunk of plastic from the backing plate. This was a BRAND new tool.

Learn from this disaster scenario and remember to lubricate that felt ring, especially if you expect to be working your Hercules Forced Rotation DA hard.

How to Lubricate the Felt Ring on the Hercules Forced Rotation DA Polisher: A Step-by-Step Guide

⚠ IMPORTANT: Read Before Starting

Before you repair, modify or take apart ANY polisher, ALWAYS ensure the tool is UNPLUGGED before beginning.

Step 1: Remove Backing Plate

Remove the hex head bolt holding the backing plate to the spindle. Keep the washers and bolt in a safe place — don’t lose them!

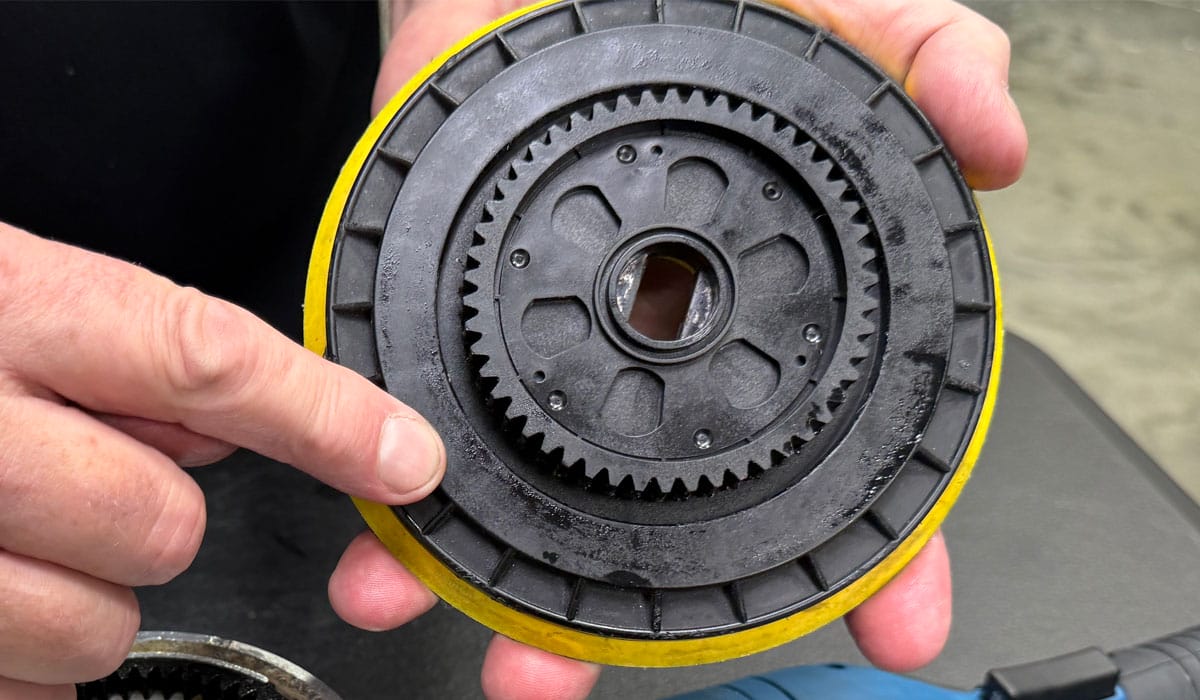

If you look at the back of the backing plate, you’ll see the portion of the black plastic that rides against the felt ring and outer lip of the aluminum housing.

Step 2: Apply Lubricating Oil to Felt Ring

Apply a few drops of a light lubricating oil to the felt ring. In the picture below I’m using Harbor Freight Air Tool Oil. If you purchase this tool at Harbor Freight after watching this video and reading this article, you may as well buy a bottle while you’re still in the store!

In the past I’ve also used 3-in-1 multipurpose oil, kitchen olive oil, even the motor oil off the dipstick in a 1966 Lincoln Continental.

Step 3: Flip Felt Ring (OPTIONAL)

The felt ring is a wear-item, this means it’s a given that over time it’s going to wear out. If you’re lubricating the felt ring after working this tool hard for long periods of time, I recommend flipping the felt ring over when you lubricate. This will give you more service life out of the factory installed felt ring.

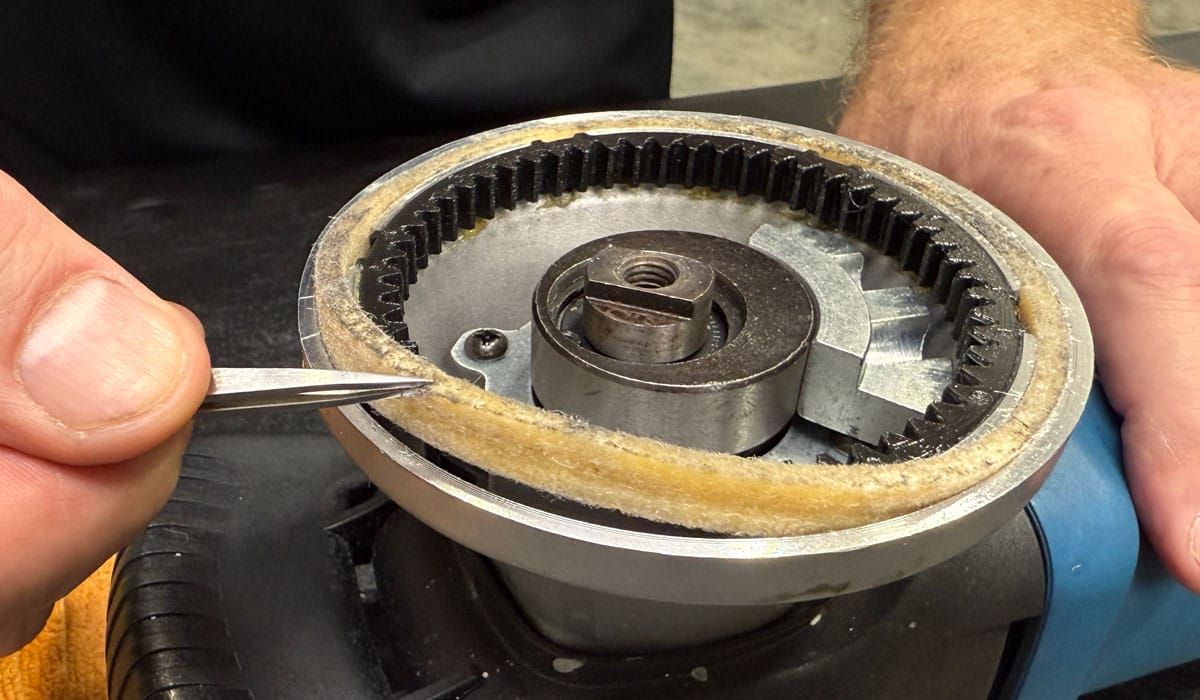

To do this, carefully remove the felt ring from the housing using a pair of tweezers or even a thumbtack.

⚠ IMPORTANT: Read Before Removing Felt Ring

Do NOT stretch the felt ring — it will make it difficult to re-install.

Flip the ring and re-insert. Lubricate the new side before re-installing the backing plate.

Step 4: Re-Attach Backing Plate

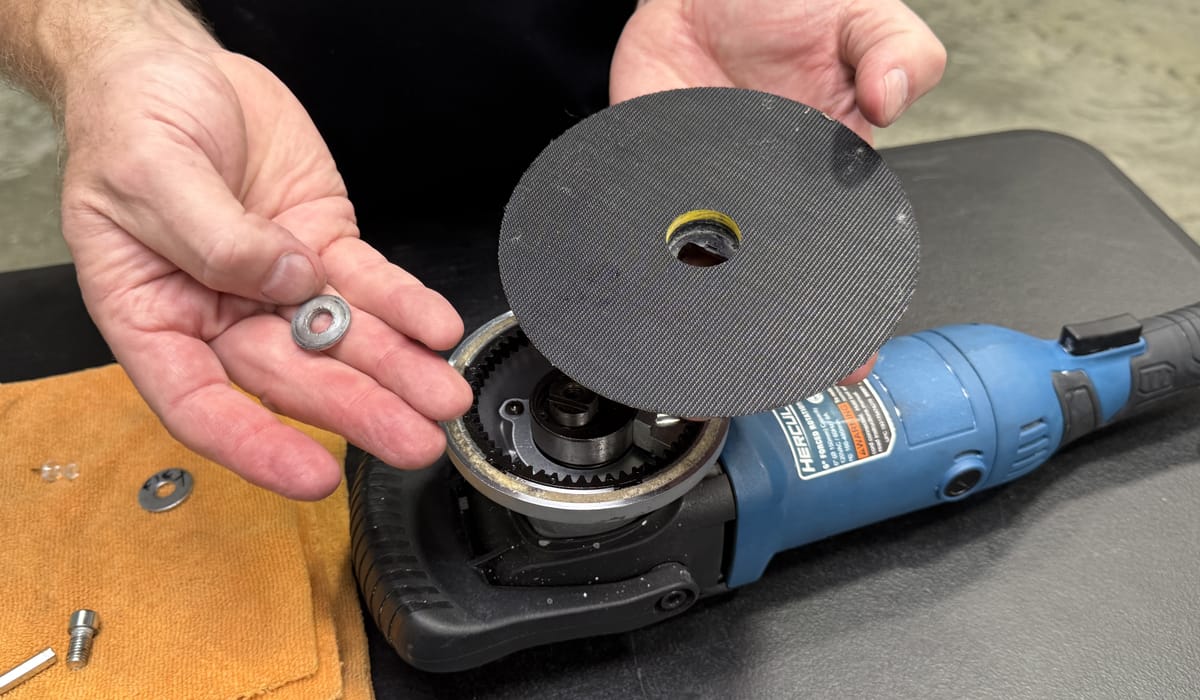

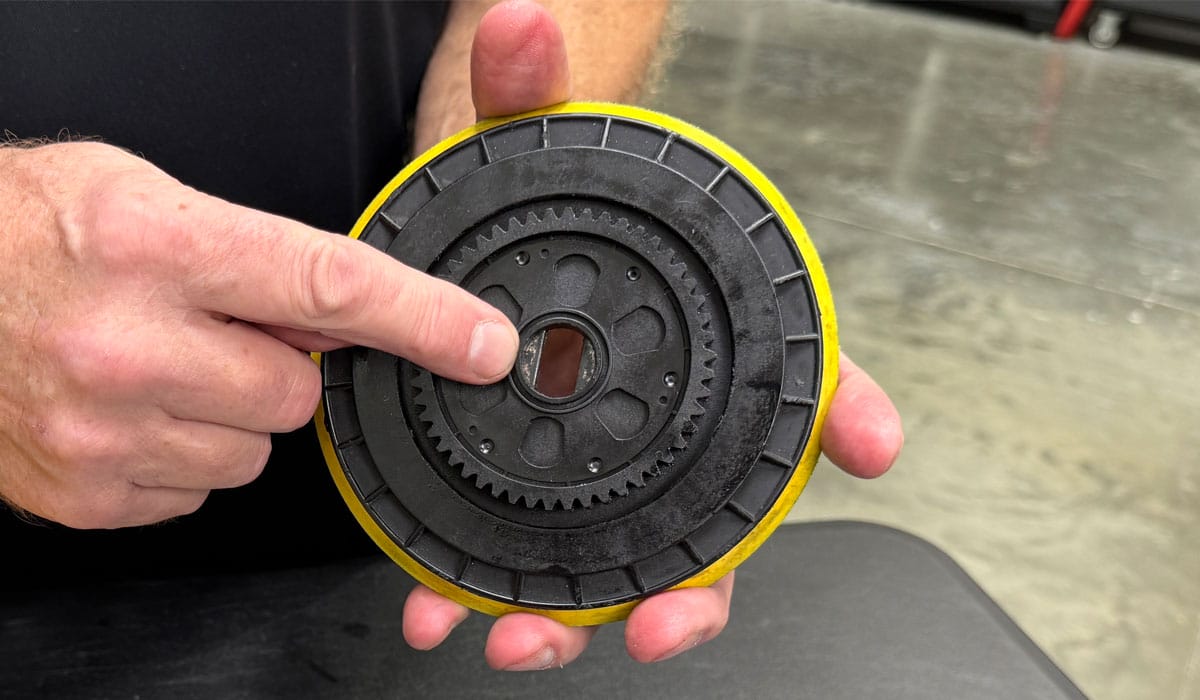

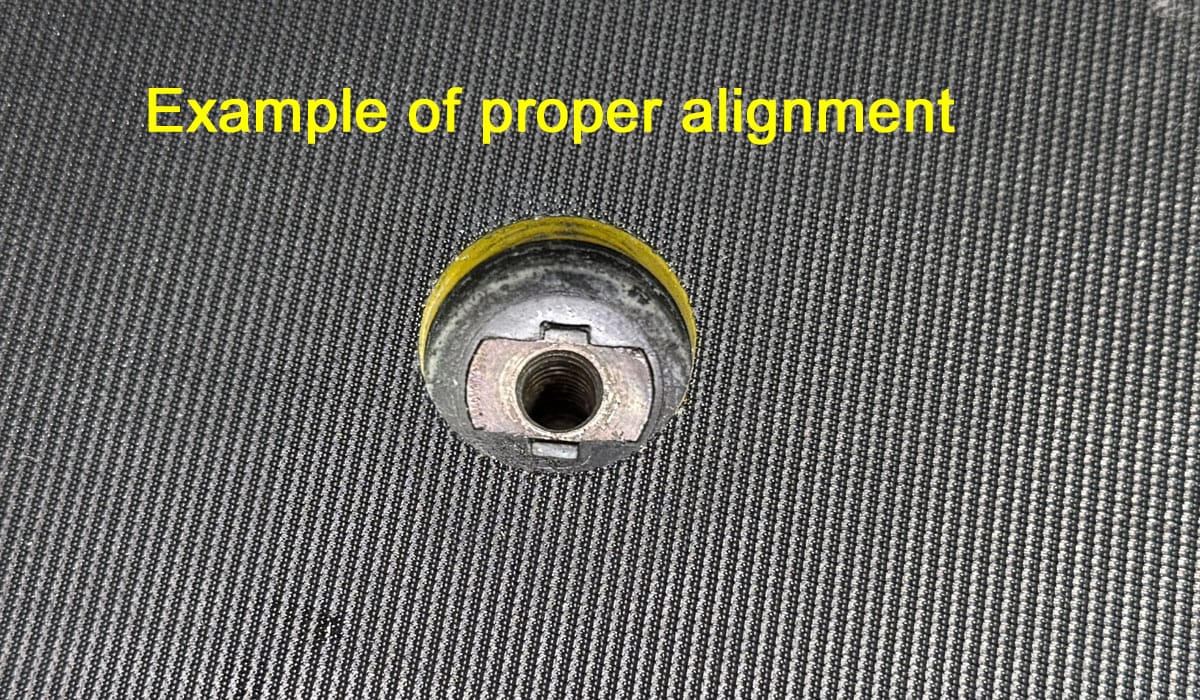

Re-attach the backing plate, being sure the slot in the backing plate is aligned with the slotted spindle.

Below are examples of improper alignment and proper alignment of the slot on the backing plate with the slotted spindle.

Step 5: Replace Factory Washer (OPTIONAL)

The factory washer that comes with the Harbor Freight Hercules Forced Rotation Dual Action Polisher is a tick undersized as compared to the factory FLEX washer.

I highly recommend replacing the smaller Harbor Freight washer with the larger 15/16” size washer you can purchase at any hardware store. For reference, a U.S. quarter is the size of the water.

The larger washer will do a much better job of providing full and even pressure against the plastic inset on the backing plate. Using and especially overtightening the bolt when using the smaller factory washer could lead to cracking the backing plate.

The Harbor Freight Hercules Forced Rotation Dual Action Polisher also comes with a locking start washer, so place this over the flat washer and then reinstall the hex head bolt and tighten until snug.

Ready To Put Back in Service!

Time to buff out this old 2-door Pontiac.

Final thoughts…

You don’t have to lubricate the felt ring. The fact is, if you never push hard on your Harbor Freight Hercules Forced Rotation Dual Action Polisher, you’ll never notice if the felt ring is lubricated or not.

But if you’re like me and need to press a little harder on the head of the polisher to remove serious swirls, scratches, water spots and oxidation, then I highly recommend this option.

And of course, it’s a good idea to remove the backing plate and re-lube the other side once in a while. Besides lubricating the felt ring, it gives you the chance to loosen and then re-tighten the bolt that holds the backing plate tight to the spindle because over time, these do come loose. The last thing you want while buffing out a car is to have the backing plate go flying off.

My Personal Offer to Help

I’ve been answering car detailing questions professionally since 2002 and moving forward, if after reading this article you have any questions about polishing and waxing, or how to use an AIO, my contact information is below, reach out to me, I’m always happy to help.

Would You Like to Learn How to Machine Polish Like a Pro?

- Would you like to take your detailing skills to a higher level?

- Do you find you learn better by doing versus sitting in a chair looking at a PowerPoint presentation about car detailing?

Here at Dr. Beasley’s O.R., (Operating Room), in sunny Stuart, Florida, we teach the most hands-on car and boat detailing classes on planet Earth. And we prove it too. You can find write-ups on the Dr. Beasley’s Blog that photo-documents just how hands-on our classes are plus you’ll see the kinds of cars and boats you’ll be training on.

Click the link below to find the dates, locations, topics, and prices for all upcoming detailing classes.

Upcoming Detailing Classes – Prices – Info – Topics – Locations

And if you ever have any questions, always feel free to reach out to me personally via text, phone call or email.

I hope to see you in a future detailing class!

Sincerely,

Mike Phillips

Chief Education Officer for Dr. Beasley’s

Mike@drbeasleys.com

760-515-0444

Questions? Comments?

Email Us