Last Updated November 7, 2025

Part 1 Transcript

Mike Phillips here and I am the CEO, or Chief Education Officer, for Dr. Beasley’s and we’re here in our Stuart facility where we teach all of our intensely hands-on classes. We recently shot a video called Beginner’s Guide to Car Polishing. And that video, out of all the videos on the Dr. Beasley’s YouTube channel, has become the most popular and the comments are out of this world. And basically all we did is Yancy, my film guy, and me, we came out here and I just tried to do what I call a brain dump on how to tackle a car if you’re a beginner.

I also included a lot of topics and techniques if you’re an advanced detailer, a professional, because I’ve been doing this a long time. And I always feel like I got something to share. And me myself, I try to be a perpetual perpetual student. When someone’s talking, I shut up. I listen ‘cuz maybe I’ll learn something.

What We’ll Cover

In this video, we’re going to be doing a deeper dive over process and technique. The different processes you use to take something from neglected to respected and the techniques and the tools and the products to go with it. Things like comparing rotary versus free-spinning random orbital versus gear-driven orbital, pad stalling, how to overcome pad stalling when you get into these concave curves.

Paint thickness gauges, how to understand the thickness of the paint you’re working on, edge work—you know, edge work is really important. I’ve got some cool micro tools to show you how to do that. I’m also going to show you how to do that by hand and using a full-size rotary. You can do it either way.

Dialing in the Details

And then we’re going to be covering things like speed, amount of pressure to put on the tool, the number of passes to make to get the job done in a timely manner, how to correctly do a test spot. I messed up in the last video, so I’m going to make up for it in this video.

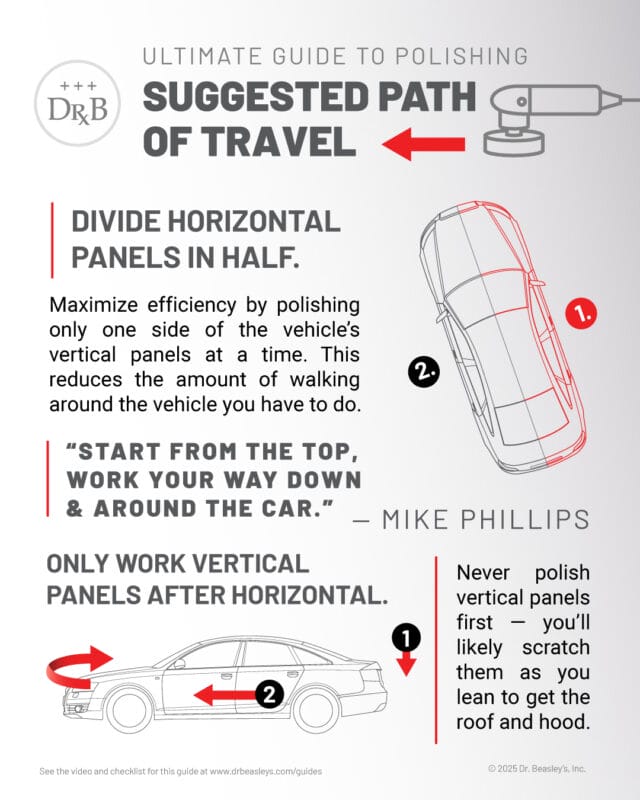

We’ll also cover topics like paint temperature. How hot is too hot? You know, when you’re buffing, you know, you start to warm up that paint. And other topics like the path of travel. So, I kind of touched on this in the other video. How do you start once you dial in your test spot? How do you go about detailing the entire car?

From Hood Panels to Whole Cars

And where most videos, including a lot of videos I’ve made, you just see the instructor standing next to the car, working on the hood. We’re going to show you how to do this entire car in this video. So, there’ll be any doubt or guesses how you should approach your car when you take what you learn here into your garage.

And of course, we’ll cover things like how many pads does it take, you know, how to use a pad washer towards the end of the video. But really, it’s just going to be a very in-depth brain dump covering process and technique. Enough of me talking. Let’s get into it.

Prep Work: Wash Before You Polish

So, the first thing you want to do before you detail a car is very obvious. You want to wash the car and get it clean. And I’ve already done that. I was down here Monday morning washing this car. First thing I did was clean the wheels and tires. Start at the top, work my way down. And this thing was filthy.

And I took a video before and some pictures to show you just how bad it was. But I think the video that we got right now after the wash shows you really how bad this car is. And this could make a great demo car just because of the paint condition.

Two Schools of Thought on Claying

Now, there’s two schools of thought on claying a car. So, I’ve clayed the entire car except I left this portion up here undone because in the last video I showed you how to use a clay bar. So, here’s kind of an example of some clay bars. This is a Mothers clay bar. This is a Dr. Beasley’s fine grade. They come in what looks like a bar of soap, an old school bar of soap.

And what you do is you take these out. And again, as I showed in that video—Beginners Guide to Car Polishing—and uh I showed you how to take a knead it and use clay the correct way. Well, this time I’m going to show you how to use a clay towel.

Clay Substitutes: Mitts, Towels, and Discs

But here’s a tip I came up with when these things were first invented. Um, when they were first invented, basically, just let me explain what this is. Clay is polybutane plastic with a pulverized abrasive in it. So the way clay works is when you rub over the surface, even though it is sticky, it doesn’t work by pulling things off. It works by abrading anything that’s sticking above the surface off and then, because it’s sticky, it holds it onto itself. So that’s how clay works.

And it’s actually a really good process. I’m a big fan of using fine grade clays on show cars ‘cuz I don’t want to put extra marring in. But after clay was invented, a couple other tools came out. We call them clay substitutes. So there’s the clay towel, the clay mitt, and the clay disc. Okay?

When to Use Each Substitute

So the clay mitt would be if you’re washing the car, after you fully rinsed it, you could actually just dip that clay mitt into your soapy water or foam the car and then rub that over the paint and clay it during what I call the wet work, during the wash process. You could also grab a clay towel and do it.

And even if you wanted to, there’s a thing called a clay disc. I don’t have one here, but that attaches to a random orbital polisher or a gear-driven orbital polisher—not a rotary—but you want an orbital polisher of some sort. And you could actually do that in the wet work process, too, as long as you’re using a cordless so you don’t get shocked.

Why I Prefer the Clay Towel

Um, out of the three, my favorite, though, besides clay, is the towel. And the reason I like the towel is because sometimes when I’m working on a car, I may need to take and fold this in a way to get into a tight area. And the clay disc and the clay mitt are just a little bit more awkward. So, they all do the same things. Personal preference. I dislike this.

But when these things first came out—and this is the Nanoskin brand, I think this is like 60 bucks. They’re not cheap. You get a lot of cars out of them, so it’s a good value for your money, especially since you understand I’m not going to drop this. But if you were to drop it on the ground, if it was detailing clay, you’d have to throw it away. With this, you could take it over the sink, wash it off, make sure it’s clean, go back to using it.

Stretching Your Investment

But when they first came out, I thought, for 60 bucks, you know, I want to know how I can get the best bang for my buck with this thing. So, I came up with a really simple idea. But first, let me just show you the way you use this. You don’t spread it out flat and then, you know, move it around the paint like that. You take and you fold it into four corner or four sections like this.

And then the idea being to get the most use out of your towel is you have to know which side of the towel you started out using. And then once it kind of wears out, go to another side. So here’s what I came up with. This is real simple. I just took a Sharpie marker and I drew a grid pattern on here and I put a one, two, and a three and a four.

Numbering the Towel for Rotation

So, when I fold this thing four ways, I’m going to start out using section one. And at some point in my detailing world, if I feel this just is no longer removing any contaminants, I want to switch over to number two. And I will tell you, as you use this—and guess what—this will kind of wear off. Just grab your Sharpie marker when it’s dry and re-put the numbers and the plus sign on there.

So, anyway, so let me go ahead and show you how to use this. So, if I fold it like this and like this and pull this up and we’ve got the number one right there. So, that’s this side. So, that’s a technique that may help you, it may not, but that’s what I do.

Lubrication and Application

Okay. So, this is actually Dr. Beasley’s Prep Wash. We do make a clay lube. You could use a spray detailer. One of the things I like about this product is not only can you use it—it is technically a waterless wash—it’s also a great interior cleaner. Uh, thank you, Russell. Um, but it also works as a clay lube.

Okay, so now let me see if you can kind of hear this. I don’t know if you can pick up on that, but this thing’s pretty rough. But the way you use this is just like I showed you. I fold it. I use—I always teach people, you know, to use this like a clamp. So, I’m going to clamp this with my thumb on one corner. The corner, not the rubber side or the rubber corner.

Technique Tips While Claying

And then it doesn’t really matter which way you move your hand, but you just want to get that thing moving. Let inertia kind of work for you. Make sure you use plenty of lube. And of course, you want to do this to the entire car.

And I will tell you, as bad as this car is, the sides weren’t as contaminated as the horizontal surfaces. And the reason for that is because when there’s contamination in the air, it lands on the horizontal surfaces.

Overspray and Contamination Patterns

Now, if it’s something sticky like overspray paint—couple weeks ago, I’m driving down the road, saw some people painting a house with a big old air sprayer. Overspray everywhere. But if it’s sticky, it will hit the sides of the car if there’s any kind of wind out there. And of course, you can have contaminants on the vertical panels. But the only way to really know that is to do the baggie test, which I forgot to show, but I will in a second.

Okay. So, once I got this side clean, again, I’ve already clayed the rest of the car just to speed this video up. Okay.

Cleaning and Reinvigorating the Towel

And then at some point, I would take this over to my slop sink. You could do this at your house in your kitchen sink. And sometimes these things stick together, but just pull them apart like that. It kind of reinvigorates the abrasive mix in the polymerized rubber. I would just lay this thing down flat. I would grab a brush of some sort like this. Actually, a little less aggressive brush, but I would just run water and even just use some hand soap and just give it a good wash. Hang it someplace to dry and you’re good to go the next time you want to use it, though.

Okay, let me show you this for some other things, too. Okay, let me grab my baggie. Hopefully, we won’t film anything after this.

Wiping Residue as You Go

And of course, as you work around the car, you want to remove that clay lube. I don’t get too bent out of shape about trying to make this look pretty because I’m just going to come up and buff it, but I do want to get any residue I loosened, any contamination I loosened off. And of course, get most of the residue off also.

Okay. And technically, I should have done this before, but this is the baggie test. Although it seems like every—Okay, that is smooth. So, the clay towel works really well.

The Baggie Test: Why and How

Um, the baggie test. Someone asked me—I had a class this last weekend. One of the students says, “Why use a baggie?” Well, the reason you use a baggie is because it’s pretty easy. Most households have it. So, you have a baggie around your house and you go out and wash your car and feel your paint.

Um, but what it does is it increases your own natural sensitivity. So, by putting that baggie in your hand, it’s easier to feel what’s going on at the surface level of your paint versus just trying to use your human skin. And so that’s what the baggie test is for.

What Not to Use

Back in the old days, a lot of guys would use cigarette wrappers. To me, cigarette wrappers, they’re kind of crispy, kind of stiff plastic. I don’t want to be scratching the paint when I’m feeling it. And when you do do the baggie test, you do want to use a light touch. You could take, if you had a flawless black finish, and rub that baggie and scratch the heck out of it.

Clay Marring Is Real

And also, let’s just talk about clay marring or clay towel marring. The act of rubbing a clay bar or any of the polymerized substitutes—the clay mitt, the clay towel, the clay disc—it’s it’s going to mar the surface. It doesn’t matter if you use a lot of lube.

Now, here’s the deal. If you’re working on a black car, probably show up. If you’re working on a light color car, probably won’t show up, but it’s still happening.

Planning for a Polish Step

So, my own general rule and what I teach in our classes here is if a car comes to the class or comes to me and I, after washing it, do the baggie test and discover it’s contaminated, I’ve already factored in at least one machine polishing step for the entire car to remove any of the marring put in by the mechanical decontamination process, whether you’re using detailing clay or a clay towel. Anyway, that’s the thing.

Clay During Wet Work: Pros and Cons

And then there’s a little bit of a controversy, but I will go ahead and go down that rabbit hole. Um, there’s two options you can—and I I prefer claying a car during the wet work. So, I got the car out there. I’ve washed it. I’ve done a thorough rinse. And that’s the key to clay a car in the wash process is after you’ve loosened up all the dirt, you really got to flush it off good.

So, at some point, if there’s—you don’t—what you don’t want to happen is a piece of abrasive particle that you loosened in the wash process, but you didn’t rinse off, and then you trap it between the rubber surface—you know, the rubber surface of the clay towel, the mitt, or the clay disc—or a clay bar and then push that across the paint to scratch the paint.

Key to Safe Wet-Work Claying

So, the key with doing the mechanical decontamination process during the wet wash is to make sure you wash it and thoroughly rinse it and then you could either foam the car or just dip your whatever you’re going to use into your soapy water. You could spray some soapy water on there or some clay lube, just something to lubricate it as you rub it.

But the problem with doing the clay process during the wash process is you don’t know if the paint is hard or soft until you do the test spot. When do you do the test spot? You do the test spot after you wash and dry the car.

Adjusting for Soft Paint

So, if you—if you—if you wash the car, rinse it, and clay it while it’s wet, and then you bring it back into your shop under the lights and go, “Wow, look, I I I’m”—The word mar is like the kind fluffy way of saying scratch. Okay? So, you scratched the car at the claying process.

The difference being is if you would have stopped and done the test spot first and found out it was soft paint, then I would try to—to the best of my ability—get what’s called an ultra-fine clay bar. So, it’s not aggressive and I would use that to clay soft paint versus any of the other options, a medium grade, a coarse grade, or any of the polymerized rubber substitutes.

Experience With Soft Paints

So, I just want to point that out because in my life, I’ve worked on a lot of cars with very soft paint and um you can see the marring left by whatever you use. So, there you go. So, there’s clay.

Okay. So, we’ve got that clay. That means this entire car is now clayed. So, the next thing we want to talk about is doing a test spot.

Test Spot: Learn From My Mistake

Now, in the last video—or that video that we shot that I referenced earlier called Beginner’s Guide to Car Polishing—um, I made a huge mistake and it was actually quite embarrassing because a bunch of people pointed it out in the comments. But one of the things I shared was back in 1988, I wrote my first how-to book. And when people in the industry, uh, around the world now use the term test spot, if you go to the index under getting started, it says right here, performing a test spot by hand. Performing a test spot by machine. The published date of this is 1998.

So, as I said in the other video, I may not be the guy that invented the term test spot, although I think I am. I am the guy that can document it back further than anybody else. And all I wanted to really kind of point out about that is I feel very qualified in teaching other people how and why to do a test spot.

Where “Test Spot” Came From

And um—and the short behind-the-scenes story of that is a lot of you younger guys won’t remember this, but in the early days of the internet, we didn’t have Facebook, Instagram, Periscope, TikTok, uh any of the stuff. Uh, but there was this thing called the Usenet newsgroups. And there was a section in there called rec.autos.misc.

And I was always up there posting how-to information. And this would be back in the 1990s, 90, ’91, ’92, ’93. I was posting how-to articles on the Usenet newsgroup and I came across a guy and this is where the test spot came from. I came across this guy and he says, you know, “Hey Mike, I I just uh compounded my entire car and after washing the compound off, I looked at it. It’s just completely filled full of scratches,” and I was kind of taken back. I was kind of aghast and I just kind of says, “Well, you know, here’s a good practice.

What you should have done is after you washed and dried the car was take that product you bought, whatever it was, and just apply it according to how you were going to apply—per the directions—and then looked at the results. And then if you found out it was scratching the heck out of your paint, ‘cuz a lot of old school compounds did that, you could have stopped right there and only had to fix that spot.”

What you did is you did the entire car. You messed up the entire car. Now you got to fix the entire car and you can’t use what you’re using because obviously it wasn’t working. So that’s where I really started putting a lot of emphasis on test spot—was trying to teach people to test whatever it is they’re buying because you know I’m dealing with people around the world. I don’t know what products they’re buying but make sure it works.

And in the detailing world let me just go down this rabbit hole. The most—the most difficult thing to make is the compounds, the polishes, and the all-in-ones, the cleaner waxes. Okay? Because they all use abrasives. And—and I—I always tell people this that when it comes to polishing paint, the most important factor is the abrasive technology. Okay?

Abrasive Tech vs. Ego

I meet a lot of detailers that are alpha males, kind of ego-driven, and they take a jacked up car like this and make it look beautiful. Then they’re kind of like, “Oh yeah, I am so good.” And you are good if you fixed it, but you were not touching the paint. The abrasive technology was touching the paint, followed by the pad, followed by the tool, followed by the tool running the tool—the guy or the girl. Okay.

So—so the most important thing is the abrasive technology because if you’re using a compound or a polish that just doesn’t use very good abrasive technology, it doesn’t matter how much technique you throw at it. If it’s—what bad abrasive technology does is it’ll remove a defect, but it leaves its own defect behind. We usually call that micro-marring or holograms, but that’s what bad abrasive technology does. Good abrasive technology removes a defect and doesn’t leave anything behind. You can go to the next step.

Start Right: Do the Test Spot First

So, if you start out using something with bad abrasive technology, it doesn’t matter how much technique or if you change tools or pads you throw at it, if it’s removing a defect and leaving its own defect, you’re really going backwards in the process. You’re—you’re not going to get the results you want. And it all started with what was touching the paint.

So, back to the test spot. The reason you do the test spot after you’ve washed and clayed the car is first to make sure you can fix the paint. I’ve come across cars with paint that’s—nobody can fix. They need to be repainted. And that’s why you don’t see this car taped off. I don’t tape off the car till I dial in my test spot. I want to make sure I can fix it.

Don’t Waste Time (or Tape)

If I—if I wash the car and clay it and I think, well, I know I’ll get it all taped off, then I’ll start working on it. And then I do the test spot and find out I can’t fix it. I just wasted time, steps, and all my masking tape. So, do the test spot first. Then if you find you can fix the car, then you want to go ahead and tape off any plastic.

And this we’re going to show you. This car has a lot of what’s called pebble textured black plastic trim. And pebble texture means if you feel it, it’s almost as though it came out of a sand mold. It has little hills and valleys. It’s very textured. And if you—if you accidentally run a compound or a polisher, say an AIO, into that, chances are really good you’re going to permanently stain it.

Old Trim vs. New Trim

Now, if the car is brand new and the trim is brand new, our products are very trim friendly. I still tape off every car just from experience. Um, but what happens when you get older plastic—like this is a 2018, so it’s 20. So that means what? 7 years old. It’s 7 years old and it’s neglected. The trim is faded and dried out. So now if you run your polisher over old trim, chances are you’ll permanently stain it. Brand new car, new trim, probably be able to get it off no problem. But once you stain old plastic trim, it’s game over. So that’s why you wait and tape off until after you’ve done the test spot.

How to Choose Your First Combo

Now, a part of that test spot that I showed in the first video where I made my mistake was if you do a test spot, and when you do a test spot, you usually use, um, you don’t want to use pads or products at the extreme. So, at one extreme, say if you got a fine cut polish, and at the other extreme, you got a heavy cut compound. Well, for your test spot, you want to kind of use something in the middle, just kind of a normal polish or a medium cut polish. Same thing with pads. You don’t want to start with a finishing pad. You don’t want to start with a super aggressive pad. You want to go right in the center. Use a polishing pad and do—and then do your test spot and then look at the results.

And if they do not look good, and here’s where I made the mistake. You don’t do the test spot in the same place, you’ve already abraded that section. Your results will be skewed. So, you need to move over and do a new test spot in virgin territory. And if that test spot doesn’t look good, then you would go to a new section.

Always Retest on Fresh Paint

So, every time you do a test spot, you want to retest in new territory. You don’t want to go back to where you’ve already been testing because your results will be skewed. And just to kind of reiterate in that last video, that previous video, Beginner’s Guide to Car Polishing, the reason I didn’t cover the importance of moving to a new section every time you do a test spot, isn’t because I don’t know to do that. It’s just a lot of times I get so my brain gets so busy trying to make sure I cover everything that I forget something and that was the thing I forgot.

Okay. So—so let’s go ahead and let’s go ahead and we’ll do our first test spot. And as we’re doing this, let me go ahead and just try to again do a brain dump.

Paint Thickness Gauges: Big-Picture Indicator

So, one of the things people are always asking about are paint thickness gauges. This is the Rhopoint coating thickness gauge. So, coating thickness, paint thickness, same kind of thing. So, the first thing I’m do is I’m just—And I have a full tutorial on this tool on the Dr. Beasley’s blog. Probably if you search Rhopoint Mike Phillips probably pull that article right up. So, let’s go ahead and turn this on.

And I’ve already done some measurements. This paint is actually—we—we believe it to be the factory paint and it’s very thin, 4.17 mils. So, let me just share what does that mean? Okay.

Mils vs. Microns (And Why It Matters)

And I know a lot of you guys measure microns and let me be the first to admit microns is more accurate because it’s just a more, uh, smaller size of measuring. So, everything’s more accurate. The problem is is I grew up in America where we didn’t use the metric system and I grew up using mils. So, one of the things that I’ve always taught people, I have an article that dates back about 20 years. If you take your average Post-it Note and pull off just a single Post-it Note and hold it between your thumb and your finger, okay, it’s pretty easy for you to wrap your brain around and go, “Wow, that’s really thin.”

Okay, the clear coat layer, not the black, not the primer, but just the clear layer of paint on a factory finish tends nowadays to be thinner than a Post-it Note. Post-it Notes are around 3 mils. Factory clear’s 2 mils or less. So, the reason I do this is so someone does that and goes, “Oh, wow. That’s really thin.” Okay. And let that sink in. Maybe you don’t want to be compounding really hard on your car because you just don’t have that much paint there.

The Dollar Bill Trick

But let me show you another way to do this because maybe you don’t have a Post-it Note handy. Here’s just a basic dollar bill. And I can’t do math in my head, but the rest of you can. But let’s go ahead. I’m going to try to measure in exactly the same place. 4.17. I’m just going to lift it up. Slide this in. 6.92. And, uh, again, I can’t do math in my head, but that’s right around 3 mils, give or take a few increments. And most people have a dollar bill. So again, you can hold the dollar bill between your thumb and the finger. Wow, that’s really thin. Okay, well that’s how thin your clear coat is.

Custom Paint Jobs vs. Factory Paint

And that’s why I like cars like this one over here. There’s a 1970 Satellite. It’s from the class we had just last week and I had eight cars here. This was one of them. We did a full paint correction and ceramic coating on it. It has a custom paint job. And when you measure the paint on it, it measures a lot thicker because a lot of times when they restore cars and they finally get to the point where they’re going to paint it and it’s in the paint booth, that painter knows it’s going to get sanded ‘cuz it’s a cool car. They’re going to try to get a show car finish on it. So they put extra paint on. So that’s one of the reasons I like.

By the way, thanks Nancy. I’m gonna keep that book. That’s our video guy in case you didn’t know. Okay. So—so that’s something to understand as a paint thickness gauge.

Don’t Get Lost in the Gadget

Now, you can buy these on Amazon for I think as cheap as like 30 bucks. The one I’m using is right around 150. They go up to the thousands. And the only thing I’d like to say about a paint thickness gauge is what I use it for is a what I call a big picture indicator that helps me to make the go or no go. So it’s going to help me to go, “Oh, that’s really thin. I’m not going to compound.” I’m not going to go. I’m not going to go that way. Or I go, “Wow, I got plenty of paint on here. I’m going to make the big picture indicator, the decision to go. I’m going to go ahead and compound it to get the swirls or scratches out.” So that’s what I use it for.

Measure a Few Panels, Then Get to Work

And this would go a little bit deeper because I covered this in my last class. You know, people do tend to get all caught up in the gadgets. I do. But here’s the thing. Um, if you’re going to use one, go around and just measure a—a few places on each of the major body panels to get an idea for what the paint thickness is. If you want to go elaborate, a lot of these paint thickness gauges will create a database you can download on your computer and you can, you know, you can really get a good idea how much paint is on every square inch of every body panel. But the thing is is you’re not getting the car buffed out, you know. So, use it as a big picture indicator. Make your decision about how aggressive or not aggressive you’re going to go and then get working on the car.

Um, anyway, that’s—that’s my take on it. And you got to keep in mind, I started detailing cars, uh, professionally in the 80s. Yeah. So, a long time now. And almost the majority of all my work, I never had a paint thickness gauge. Heck, I didn’t even know what they were. And here’s what I did instead. I use good abrasive technology. I use the right tool for the job and good technique. And all my stuff comes out without a problem. So, don’t get too caught up in a paint thickness gauge.

Pads First, Then Tools

Okay, so we’re going to do a test spot. So, the first thing I do want to talk about is pads. Now, in this video, we’re going to be covering primarily foam pads. Uh, in a future video, we’ll be covering microfiber pads and wool pads, but this one we’re going to stick with foam. And I have the Buff and Shine line here, but it is—there’s a lot of quality brands of foam pads on the market. So, just pick a brand and go with it. I do particularly like this brand and I’ll tell you why in a second.

But you can see there’s a color code here. We got a light blue, a maroon, a medium blue, yellow, white, and black. There, I’m sad to say there is no universal color code system in the industry worldwide. Every pad manufacturer just comes up with their own color scheme.

How to Tell What Pad You’re Holding

So the—the question I get all the time is how can—how do I know what the pads are? Well, first of all, you could go to the website and look at the—what the—the manufacturer shares. I mean, for this pad here, it’s probably going to say soft foam finishing pad. There, I know what it is ‘cuz I went to the website, you know, do your research.

But if for some reason you have some pads, you have no idea what they are. Here’s how you can tell what they are. Just take your clean hand and feel the surface. A foam finishing pad will be very soft. And then let me go to the extreme opposite. Here’s a very aggressive foam cutting pad. And when I feel it, it’s sharp. It’s got a sharpness to it. It’s also denser. Okay, it’s harder to squish.

Not All Foam Is the Same

So, there’s two ways besides even looking at the back where it says blue heavy cut. So, there’s all different ways to find out what the pad is. And it’s kind of up to you to figure that out. But, I just wanted to share that when you feel it, you can feel the sharpness or no sharpness. And as—as I went through these, like this has—this has no real cut. This is a white polishing finishing pad. This is a yellow polishing pad. I can feel a little bit of cut there, not a lot. And then as I get to the blueberry, little bit more, the maroon all sudden it starts getting sharp. So there are varying grades.

And just to kind of throw this out there, you know, a lot of people think foam is foam. But what you don’t know is the people that make the foam add chemicals to it to make it do things. It’s not just foam like you get in your camera case. There’s chemicals in there for the polishing world to make it do different types of things. So there is a science to making foam pads.

Entry-Level Tools and Backing Plates

Now, so we’ve covered the pads. Now we’re going to cover tools. Now, in the last video, I shared with you a tool, and this was because we’re targeting this video at beginners, people that have maybe never polished out a car in their life. And so, if you’ve never done this, I mean, there’s a lot of great tools. I got $50,000 of the tools back there. Some are as high as 8, 900 bucks. But if you’re new to it, you might want to start out with just an entry-level tool. See if you even like this. You might buff out the hood and go, I’ll just let it go, or I’ll take it to a detailer, or I don’t care. And if you do like it, then after watching this video, I’m going to show you some tools that cost more but work better.

But let’s go ahead and we’ll start out with this entry level tool and we’ll do our test spot. Now, the first thing I also want to cover is look at the backing plate size on this. Let me put this in order. You read left to right. So, this is a 6-in backing plate. This is what this tool comes with. It’s a 6-in backing plate. I have put a 5-in on a similar tool. It’s the same exact tool that they change body styles and logos, but this is a Bauer 8 mm free spinning random orbital polisher.

Swap to a Smaller Backing Plate

And in a previous video we made on this tool, I highly recommended to go ahead and after you buy this tool, take that backing plate off and go to Amazon. This is a CASOMAN—can you get in there and see that? I’m sharing this because people send me messages. Mike, what’s that backing plate? So go to Amazon, type in CASOMAN. You can find two of these for 10 bucks. And yeah, they’re not high quality. They’re cheap, but you get what you pay for. But it’s really probably one of the least important ones that comes with this tool.

But let me show you why I recommend going to the smaller backing plate. Here is a 5-in pad, and here’s a 6-in pad. Look how much more surface area there is for that tiny little tool to try to rotate and oscillate. So, by putting a smaller backing plate on there, you’ll get better performance out of the tool, especially if you’re experiencing pad stalling just because you got less surface area that you have to try to rotate and oscillate.

Picking the Right Polish From the Line

Okay. Now, this tool in that video, we ran into some stalling problems. So, I got some other tools here and I’m going to show you how to overcome pad stalling in multiple different ways, but let’s just go ahead and we’ll start out with this. And if you remember what I said, I said you want to start right in the middle for your test spot. So, this is a foam polishing. It’s not cutting. It’s not finishing. It’s right in that sweet spot we talked about.

And in the Dr. Beasley’s line, we have the Core Cut Plus, which most people should never be using. It cuts so fast. We got the Core Cut. This is like our compound. Cuts really fast. Then we got the NSP 150, the NSP 95, 45, and the Z1. What these numbers mean is the diameter of the abrasive particle.

What “Abrasive Technology” Looks Like

So, we use a—a part abrasive technology that is exclusive to Dr. Beasley’s in the United States. It’s called microspheres. Here I have some back here. A lot of people don’t know what I say when I say abrasive technology. So let me help you to understand. Here’s the Core Cut 1.5 microns. And I’ll take some out of here and just kind of show it to you. That is what we talk about when we say use abrasive technology. In the industry a chemist would refer to it as powders or grains. Okay, I just call it abrasive technology. But that’s what it looks like before it’s turned into a product.

Why the Nano Gel Matters

And then because someone in the last video says, “What makes your products different from everybody else?” Well, our products are 100% inorganic. That means they’re not made of anything that grows out of the ground or grew out of the ground at one time. This is our nano gel. It’s 100% inorganic. So, this is what you put the abrasives in and you create one of these products that you would see over here.

Primer Without the Wipe-Down

And then the benefit to the nano gel is because it’s 100% inorganic that after you use it, you can go right to the ceramic coating. With pretty much, I think every other product on the market, including the ones that say primer—‘cuz that’s how we describe ours as a primer because it primes the paint for the coating—they’re made with mineral oils, um, petroleum distillates, things like that that are organic, and you need to use a panel—like panel wipe like isopropyl alcohol or mineral spirits—to wipe those oils off so the coating can actually bond to the paint.

So, I’m not a big sales guy on product, but I did want to cover that up because there was quite a few questions about that in the last video.

Setting Up the Test Spot

Okay, so we talked about our tool, we talked about pad choice, and for this I’m going to go with the NSP 150. In, uh, my estimation, this would be the closest thing to the average polish on the market today. Here’s another technique. Here’s a Sharpie marker, and let me show you a real important thing you can do, no matter what brand of polisher you’re using.

Uh, as you can see, I’ve already taken and put a black mark on the backing plate. And I’m going to put one on the pad. But here’s why. If—if that black mark wasn’t there, when I turn this thing on, um, the yellow backing plate, the yellow pad are just a blur of yellow. It’s really hard for me to tell if the pad’s rotating and oscillating or if it’s just vibrating or stalling out. So, this is a real way to make a quick visual indicator. Mark the backing plate and the pad or just mark one or the other. Um, so just like this. And then I think you’ll be able to see when I start polishing what I mean by that.

Where to Place the Test Spot

Okay. So, we marked that and we’re going to do our test spot, uh, with NSP 150. I put it up here already. So, when you’re doing your test spot, you want to pick a panel. The—the best panel is a panel you can look down on. I see some guys doing on the side of a fender. I’ve done that too. That works too. But in most cases, it’s the horizontal panels, so the trunk, the roof, and the hood that tend to take the most damage from Mother Nature. They take the brunt of the damage and even from us when we’re washing it, you know, and things like that.

Um, so that means it’ll have the worst defects. So, if you dial in a process that fixes one of the horizontal panels, chances are good it’s also going to fix the vertical panels. If you do a test spot that fixes the vertical panels and they’re not as bad shape, then you do the horizontal panels, you might go, “Oh, this isn’t working. It worked good on the door. It’s not working on the hood.” So, always do your test spot on a horizontal panel that you can look down on. That’s why I’m not doing it up here on the roof. I can’t really look down on that.

Best Practice: Work From the Center Out

And then, normally when you detail a car, and, uh, I teach this in all my classes, you need to have what’s called a best practice. You need to have a method to the madness. And when you’re buffing out these larger panels, you don’t start buffing here and then work your way out to the center at some point. You start in the center and work your way out. Then I’d move down and start in the center and work my way out. I might come to the front, start here and work my way down. But you don’t start on the outside of the car and go to the inside. You start on the inside of the car or the panel and work to the outer edges.

Uh, but for the test spot, I’m just going to do my first one right here. Oh, see here it is. I—I forgot I put it on the windshield wiper. So this is the NSP 150.

Priming, Drops, and Pad Choice

And to start out, whether you’re using a microfiber pad, a micro wool pad, or in this case, a foam pad, because the pad’s dry, I kind of like to—A lot of guys talk about pea-size drops. I like to add dime-size drops. Okay? And you know, there is—there is the topic of pad priming, pushing this all over the place, and you can do that. The idea being is once you put the abrasive technology over the entire face of the pad, when you turn the tool on, 100% of the pad goes to work for you.

But in my older age, I’m getting lazy. So, I just let the product migrate around on its own. But, however you want to do, I will say if you’re going to get into microfiber pads, it is important to go ahead and prime your pad. And the idea being is to coat each individual fiber or most of them with the abrasive technology just so you have uniform cutting. Uh, better pad rotation, better pad oscillation. So, priming a pad for microfiber very important—with foam just less important. Look, all my cars come out looking good and I don’t prime pads. So, figure that one out.

Section Passes and Arm Speed

Okay. Cord over shoulder. And this is an important technique just so you don’t sit here and drag this up and down the side of some dude’s car or your own car. Okay. And then what I’m going to do is I’m going to make a series of section passes. Let’s talk about section passes. You know, um, you’ve got thin panels. Where’s the, uh, the fender there? The top of the fender. There’s a thin panel there. You’re not going to do a crosshatch pattern on a thin panel. You’re going to run the polisher the direction of the length of the panel. This just makes common sense.

But anytime you can cross-hatch, you should cross-hatch. And that’s for what’s called UMR, uniform material removal. You’ll remove just as many swirls here as you do there as you do there, because you did a very consistent and equal polishing process.

Underdo Your First Test

Now, real key when you’re doing a test spot, and you can kind of determine how you want to do this, but—but you want to—you want to either count how many seconds you’re polishing or count how many passes you’re polishing and use what’s called a slow arm speed. Arm speed is how fast you move the tool over the surface. You want to use a slow arm speed.

So, some people like to count seconds, but for me, I—I just can’t do it. I can’t sit here and go one Mississippi, two Mississippi, you know, 80 Mississippi, 90 Mississippi. So, I just like to count my section passes. But whether you do time it by seconds or minutes or count your section passes, the really big picture point idea when you’re starting your first test spot is underdo the amount of section passes you—you would think you would do.

Map the Section, Then Go to Speed

Because if you—if say if I did eight section passes and I wipe off and the scratches are gone, I never knew at what point they were gone. They might have been gone after the first section pass ‘cuz the paint’s soft. But if you overdo your section passes, there’s no way to know. So underdo it for your test spot. So in this case, I’ll just go. This paint’s really bad. And I have no idea if the paint is hard or soft. But I’m just going to do four textbook example section passes. Then we’ll wipe off and inspect. And then we’ll go from there.

And the other thing I just want to point out, and I teach this to people all the time, you can blame me or not, but when you’re by yourself, if you dial in a process that say you’re going to do eight section passes to every section to get the defects out to your satisfaction, I count them out loud. Otherwise, I forget where I’m at. And then I do more passes to make up for the ones I don’t know that I didn’t do, and I spend another hour buffing out the car. You save an hour easy by doing this technique.

Spread at Medium, Polish at Max

So, here we go. And speed settings. So, someone asked me about speed setting. This has a dial. Most of these tools go from 1 to 6. This is on the 1. You know, I would never use the 1 for anything. If I was going to do some machine damp sanding with this, I’d probably be on at least a 3 or 4. But to spread your product out, if you’re new to this, here’s a good idea is put on a medium speed. Set something like 4. Turn the polisher on. Spread your product out. Spread your product out. And this kind of maps out in your mind’s eye the size of the section you’re going to do.

And for, you know, this is what I would call a wimpy tool. For a wimpy tool, you’re going to do a section about the size of a microfiber towel. And that means when you buff out the car, you would start in the center and go here. Then you might go here. Then you might come to here, then go to here. But each time you’re going to do that size, the size of a towel. And you’re going to overlap a little bit into the previous section for UMR, uniform material removal.

Monitor Rotation and Keep the Pad Flat

Okay. Now, as you look on here, what you see—can you bring this camera down and show that? This is what I call a uniform layer of two things. So you have abrasive technology and lubrication. Okay, the lubrication in our case is the nano gel. It’s the thing the abrasives are embodied in. And it takes both to create beauty. Okay, if I threw a handful of sand on here with some water, it’d probably remove the swirls and scratches, but it wouldn’t look very good ‘cuz that’s not a very good abrasive and is a horrible lubrication.

Okay, so then once you do that, I’m going to take and I’m going to turn the speed all the way up to 6 on this tool. I’m going to monitor for good pad rotation. And if I don’t see the pad rotating, I will check to see if I’m holding the pad flat to the surface. A lot of times I see people buffing like this. They push down on the back of the tool. There’s an air gap in here. Only the back of the pad’s working. It ain’t going to rotate very well.

So, you want to keep that pad flat. And that means you put all the pressure up here. You could actually put your hand under the tool, which would keep you from pushing down on it. You could pull down on it, but it’s just a technique to teach yourself to keep all the pressure up here and keep that pad flat to the surface.

And then, of course, I will use a slow speed, arm speed. So, here we go. One, two, three. Okay, there was four textbook examples of a four section pass. Textbook example of four section passes. Slow arm speed. I did a crosshatch pattern and I overlap by 50%.

Clear Coat Check and Towel Setup

Okay. And first of all, just real quickly, there’s just white product on here, which tells me we are in fact working on a clear coat. Had this been a single-stage paint job, which it could happen, someone could repaint this Mustang and use single-stage urethane or lacquer enamel, I would have pulled pigment off. It would—the pad would have turned black.

So, real quickly, all my towels are already pre-inspected. I use tweezers for that. When they come out of the dryer, I feel them. I look at them. I make sure there’s nothing on them that could put a scratch in paint.

Why I Like These Towels

And then I—I love these towels. I get these at Auto Fiber. Uh, they’re sold as a glass towel. Uh, but they have a loop kind of like a bath towel. A la a bath towel when you go to get out of the shower and dry off. Um, they have a—a loop. It’s called the nap. And how that works with this towel versus a towel with just open fingers—they’re split open-ended fingers—is when you push this against the product, that—that loop—uh, how can I make a loop? That loop tends to slice into the film, breaking it up, making it easier for me, you—me—to wipe off.

But then some people will say, “Well, Mike, that has an edge that you weren’t—you going to scratch the paint because it’s got this silk edge.” Well, I don’t do stupid stuff. I don’t rub the paint with the edge. So, look at your hand. Here’s your index finger. This is your clamp. After you fold it four ways, clamp the edges. Lay your towel down flat. Spread your fingers out. Kind of scrunch it up. Now you’ve got really good towel control.

Wiping Technique and First Results

Doesn’t really matter on the horizontal surface, but on the verticals it does ‘cuz you don’t want to get your towels on the floor. They get contaminated, put scratches in paint. Then just come down and use an overlapping circular motion and wipe off the residue.

Okay. Now, camera guy, can you see the difference between that stuff or do you need the light? Okay, so let’s bring a light in here. So, we’ll start out. By the way, this car has a lot of rock chips, so we’re planning to bring it back. Am I getting it for you? We’ll go forward. We’re planning to bring it back and do a video on how to do rock chip repair.

Evaluating the Test Spot

Okay, so let me tell you what I see compared to over here. A billion times better. And it’s a very nice dark finish. I don’t see—I do see some micro-marring. Okay. So, what that tells me is this paint’s probably pretty soft because I’m using a polish and a polishing pad. And even the pad can leave its own scratch pattern. So, to finish a black car out or any color car out perfectly, if you are seeing micro-mar, that means you need to switch to a less aggressive product and a less aggressive pad for the final step.

Um, anyway, so when I look at this, you know why—it does—it does look good. There’s still some deeper scratches here and there. I mean, this thing again was used as a hockey puck. So, I’m going to go ahead and do a second test spot. And I’m going to—I’m going to increase the level of cut.

Heavier Cut Second Test Spot

So, I’m going to go with the blueberry and in the Buff and Shine line. This is called heavy polishing. So, it’s a little more aggressive than just polishing, which is what I had on the polisher. Okay. So, we’ll pull this off.

Now, at this point, I could just stick with the NSP 150. Uh, but the guy that let us borrow this car, I also did commit to him to do a really good job. So, I’m going to cut this thing hard and really try to put a—the best finish that this paint can take back on it. But here’s our Core Cut. And this is a very sharp abrasive technology.

Product Amounts and Splatter Control

So, back to our dime size ‘cuz it’s a brand new pad. Once the pad kind of breaks in, then I would start using pea-size drops. Now, instead of doing the test by here, I’m going to move over. In fact, I think—can you capture if I do it up here? So, I’m going to go up here and just kind of get out in the middle here.

Okay. And again, uh, couple—couple techniques I didn’t cover a second ago. Before you turn a polisher on, make sure it’s in contact with the paint. Otherwise, you’re going to throw splatter everywhere.

Spread, Then Two Section Passes

Okay. I’m—I’m going to turn it down to the four just to spread my product out. Okay. That’s not included in section passes. That’s just getting it spread out so I have a uniform layer of abrasive technology and lubrication. Now, I’m going to do—I think I’ll just do two section passes and we’ll lift off and see how that looks.

Okay, two textbook examples of a section pass. I didn’t count those ones out loud. I usually do. Let’s check out what two passes will do.

Inspecting After a Heavier Pass

Oh, yeah. And when you’re—when you’re wiping off, you want to take just little bites at a time using an overlapping circular pattern. And in most cases, when you use that technique, everything will wipe off nice and easy.

Okay. So, now let’s—uh, when I look at it, you know what? It’s—a lot of the deeper scratches are gone, but let’s go ahead and throw this finder light. I still see a few deeper scratches in there. Am I—am I good? Okay. Here’s the second test spot. Better defect removal just by changing the pad to something more aggressive and also changing the abrasive technology to something more aggressive.

How Perfect Is “Perfect Enough”?

Now, when we talk about is that good enough? Well, that’s a great question. And one of the things you got to do, you got to take into context what the car is, how it’s going to be treated when you’re done detailing it, whether it’s yours or you’re a professional doing it for someone else. And that will kind of let you know just how far am I going to chase these scratches.

Okay, this thing has a lot of deep scratches in random places. And because we measured the paint and the—the paint’s measuring anywhere between a low of 3.8 mils to a—a high of 4.8 mils, you know, with a mil in there, that’s—to me that’s thin paint. I don’t want to get too aggressive with this because, um, I—I haven’t checked with the owner, but to my knowledge, this thing sits outside all the time.

Managing Expectations and Protection Choices

So, trying to get every single scratch out of this car would mean removing a lot of the already precious thin clear coat that’s on it. And it’s already, uh, 2025. This is a 2018, so—7 years old. You know, it’s getting close to 8 years old. So, I want to take that all into context and go, you know what? I want to get pretty good, but I’m not going to look for perfect.

And here’s how I would normally do that for a car like this. You just saw me do two section passes with Core Cut and a, um, heavy polishing foam pad on a simple DA and I removed, you know, easily 90–95% of the defects. I would call that good. I—I would say, “Hey, that’s—that’s what we’re going to get.”

Talk to the Owner About Washing

You know, if the owner says, “Well, I want it perfect.” I would—I would try to educate him and I’d say, “Look, you know, the guy’s name is Brian. Look, Brian, you know, um, when you brought it to me, it’s pretty jacked up. So, I don’t know if you bought this new or used, but whoever’s owned this car, they have not been taking care of it very well, you know. So—so for me to go in and make it perfect, just to go back into the world it came from and get scratched up would just be a waste of time.”

So, keep those kinds of thing in context when you determine just how perfect you want to chase. Another thing is—is anytime I detail a car for somebody else, the first question I ask them and the first question you should ask them is, “How do you wash the car?” That will tell you everything they know about take care of the paint on their car.

Using Inspection Lights Correctly

If they say, “Well, you know, right down the road for me is a swirl-atic car wash, automatic car wash. That’s where I take it ‘cuz it’s convenient.” I wouldn’t even try to get it this good because soon as he takes it to the car—wash one time—is going to start putting scratches in. Now, if Brian says, “Well, you know what? After you get it done, I love this car. I’m going to wash it carefully like that video you show on how to wash a black car and try to keep it as nice as I can and hopefully never have to see you again.”

So, knowing how somebody washes the car will help me to determine how far I want to go as far as the paint correction and also whether I’m going to use a wax or a ceramic coating or a synthetic paint sealant. So, I always ask my customer, how do you wash the car? It’s always fun to actually hear them describe what they do.

Distance and Angle Matter

So, you saw me inspecting the after results using what’s called an inspection light or some people call it a swirl finder light. This is the Scangrip brand. I think they’re one of the early, um, innovators in the marketplace. I think most people would agree they have the best inspection lights. They’re also the most inexpensive. So, whatever works for you. I just like my Scangrip.

But let me give you a couple tips and techniques on how to correctly use it. Now, I had a class this last weekend. Had 16 people here. 13 people flew here from out of state, including three from California. And we detailed eight cars, including sanding two of them. So, we’re talking about an intense class. And, of course, I showed them how to use an inspection light.

Common Mistake With Lights

And even after showing them, I had people doing this. Can anybody say what’s—tell me what’s wrong with this? Pull that light up. You want to put it about a foot and a half off the paint. And you want to angle it at a 45° angle to your eyes so you can correctly see what’s going on with the paint.

When you put it down really low like this, all it really does is blow out the paint. You don’t really see what’s going on, especially in any of the surrounding areas. So, you want to hold it about a foot and a half off the paint. Hold it so it’s at a—it bounces the light to your eyes at a 45° angle. And that’s how you use one of these inspection lights. Real handy.

Gadgets Build Trust

And another thing you can do is, you know, this—this video is kind of just targeted for people that are brand new to polishing, whether you’re an enthusiast or professional. But I always teach people that when you’re—if you’re doing this for money and you’re talking to a customer, it just kind of helps if you can show them cool gadgetry things like the swirl finder lights because they probably never seen one and it just helps them to trust that you actually know what you’re doing. Uh, because you know about the things they don’t know about. They probably never seen one.

Dialing In More Cut (Then Finishing)

Okay, so we dialed in our test spot and we found out that with just two section passes with our Core Cut, we left this paint looking pretty flawless. So, what I want to do is two—for me, two section passes. Eh, I think I could probably pull out more by doing four. So, I’m going to go ahead and do two more and then we’re going to start talking about pad stalling.

Well, actually, I’m going to do the second step ‘cuz remember I said this paint is soft. In fact, uh, let’s talk about hard and soft paint. The fact that I was able to pull 95% of the defects out using two passes with a polishing pad and a—and a compound tells me that the paint’s pretty soft. If it was hard, I’d had to make eight, nine, 10 or get a more powerful pad—tool, more powerful pad.

Plan a Two-Step on Soft Paint

So that tells me it’s—this paint on this thing is soft. But also, I saw some micro-marring. Okay? And a lot of times that can be left by the sharpness of the pad. And that tells me that in order to get this thing perfect, I can’t just do one step with a heavy paint correction step to remove the majority of the defects and stop. I need to do that step and then come back with something less aggressive to make sure the paint’s perfect in the sun.

So, uh, to do the—set, let me do two more steps with this. So, that would be a total of four section passes. And when I’m doing that, I want to talk about how much hand pressure to put down.

How Much Pressure and Speed

Okay. So, now you can see the pad’s kind of broken in. You can see the—the NSP has migrated around the pad. It’s—now it’s—it’s actually—it’s not wet, but it’s damp with product, and that’s kind of what you want. And now I’ve put on three pea-size drops. Okay.

So, let me do two more section—solid section passes. I’ll count these out loud. But before I start, let me talk about how much pressure to put down.

Gauging 5 Pounds of Pressure

Okay, so, um, you don’t want to just use the weight of the tool. Uh, what happens when you do that is the pad kind of flutters. It’s not very smooth. You’re not going to do anything. So we know we need to add at least some pressure, but you don’t want to add so much pressure that you’re denting the sheet metal or, uh, bogging the tool down.

So a good way to use this tool is to just add about 5 lbs of pressure. Now, this tool weighs about, I think, six pounds. So, lift it up and feel it and then try to duplicate that with your hand. Uh, about 20 years ago, I wrote an article showing how to gauge pressure. And what I did is I took a bathroom scale. I put a piece of clear plastic over it—so I wouldn’t get polish on it. And then I actually put polish on the pad and put my hand on it. It was a Porter Cable. And I pressed down to show 5, 10, 15, and 20 lbs.

Practice Pressure on a Scale

And then I just encouraged everybody else, if you really want to learn how much pressure to put on the head of a tool, do that same thing. Get a bathroom scale, put your pad and your tool on there, and then apply pressure till you see that scale move in the direction you want to see it move and—and get a feel for what about 5 lb feels like. It’s not super rocket science. The point is you want to add some pressure, some light pressure.

And then my arm speed was slow. And what was the other thing I wanted to cover? Oh, the tool speed. Um, a lot of people are worried if this your first time about burning through the paint.

What “Burning Through” Really Means

And when you talk about burning through the paint, what that means is in the—in the case of this car, this has got a base coat/clear coat finish. So, when this car was built, they put on what’s a e-coat, or I think it’s called an electric coat. I forget what that’s for. Then they put the primer on. And then they—the e-coat may have to do something with rust proofing it. Then they put the primer on. Then they put the base coat. That’s the color you see. Then they put a layer of clear paint.

And a lot of people think clear coats aren’t paint. They’re paint without pigment. So you’re—if you’re working on clear coat, you’re still working on paint. It’s just clear paint. Just keep that in mind. You know, whether it’s base coat/clear coat or single stage, it’s all paint.

Avoid Edges and Raised Body Lines

Okay. So now when we talk about burn through the paint in the context of this car, what that means is you would take off so much clear layer that you would turn your pad over and see the black coming off. That’s a really bad sign. You don’t want to see that. And a lot of times when I’m doing custom work—like I actually sand down and cut and buff a lot of cool cars like this every year, like four or five a year. And one of the things I always show when I’m shooting a video or pictures is the—whatever the color of the car is—you don’t see it on my wool pad or my foam pad when I’m done. That’s the goal. Do the whole thing without ever striking through or burning through the paint.

Uh, but here’s the thing. These tools are really safe. I showed this in the last video. I’m going to pump this down to the four setting. And, you know, I understand you’re scared, but here’s a couple things. One is don’t ever buff on top of raised body lines or edges. So there’s this inset here where there’s a fresh air intake. And right here where this plane meets this plane, there’s a raised body line.

Why Edges Are Thinner

With the raised body line, a lot of times the paint may be thinner for a couple reasons. First, when they painted it, because it’s a high point, gravity causes the paint to flow downward. So the high points can be thinner just naturally from the painting process. But the other reason it could be thinner is through normal wear and tear. Maybe this car is washed a thousand times. There’s some kind of wear taken place there.

But another reason why is because if this car has ever been buffed out for somebody before me, and I don’t know what they used, maybe they used what they call a—I call a caveman compound. That means crap for abrasive technology. Call it rocks in the bottles.

Maybe they used a wool pad like this. So nothing wrong with this. I’m going to show how to use this on this car. But here’s a wool pad on a rotary. But they use that in conjunction with a real junky compound. And the effect is—is they remove the swirls and scratches, but all the raised body lines and all the edges, they left the paint thinner.

You come along using all good stuff with good technique. Make one pass and you go through because the other guy left it, as I like to say, whisper thin, very thin. So, was it your fault? It’s his fault. But guess who’s going to take the hit? You are.

Buff Next to the Edge (Not On It)

So that’s why I tell people when it comes to an edge, buff next to it, but don’t put that polisher right on top and buff on it, okay? You know, it’s just ridiculous. Just get close to it. No one’s going to come around your car and go, “Well, you know, Mike, you really did a good job, but right here by the edge, I still see a few swirls.” You know, let him buff out the car next time. Uh, so just try to bring some common sense to it.

Speed, Pressure, and Dual-Action Motion

Okay, so downward pressure about five pounds. Uh, for these wimpy kinds of tools. Seriously, you really want to be on the six speed. What you want to do is when you turn it on is you want to see good pad rotation and good pad oscillation. You want to see both, not just one. I see a lot of people always talking about, I don’t see no rotation. Well, I want rotation, but I also want oscillation. That’s the function of this tool. DA polisher, dual-action polisher, two actions.

So now I’ve marked this. Now I’m just going to put down 5 lbs of pressure. I bumped this all the way up to the six. And when you’re first starting out, it’s completely fine if you want to put it on three. There’s three. I still got some pad rotation. Okay. And—and just get a feel for the tool. Get a feel for the sound. Get a feel for the vibration. Get a feel for it. But as your comfort level comes up, you’re just going to find you’re going to be faster overall and more efficient if you bring it up to a higher speed.

Brand-Specific Speed Guidance

I will, out of respect to my friends at Rupes, they design all their tools to be run on the four-speed setting and then if you run into a concave curve or an issue with pad stalling because you’re on a thin panel or something intricate, then bump it up to five or six to power through that difficult area, but then back down to the four.

But when I’m using tools like this from Harbor Freight, I just put it on the six and just kind of set it and forget it. In fact, some tools I’ll even tape the speed setting on at the highest speed setting so I don’t accidentally bump it and bump it down ‘cuz I want to get done at some point.

Finishing the First Step (Four Passes)

Okay, let’s go ahead and do our other two section passes. That would be three. Okay, that’s a total of four section passes. No black paint. Remember, that’s a good sign. Sit there and we’ll wipe off. And then we’re going to dial in the next step.

This was just because I know I could get more defects out because I only did two in the first place. And that was just to teach you a lesson that when you’re doing your test spot to under—underdo the amount of passes you do. So you know at one point this paint’s also kind of sticky. At what point the defects come out.

So that is absolutely much better. So let’s go to the next step. Now, I need a—a process to come back and polish that to make sure all the micro-marring’s removed because this is soft paint.

Soft Pad + Finishing Polish

So, for that because it’s soft, I think I’m going to be able to get away with this really soft foam finishing pad. In fact, it’s so soft this morning before showing up to work, I put my makeup on with it. Yes, it’s that soft. My wife uses one, too.

Okay, center it up. Here’s a little tip for putting pads on. The Edge Guard is kind of different because it’s got this, uh, plastic liner that runs around the diameter of the pad. Then you got the Velcro. And for this backing plate, it pretty much self-centers. But if you don’t have a pad like this and it’s just flat on the back, what I will usually do is I will—as I get them closer—I will touch the back of my thumb to the backing plate. Okay. So now if I am ‘cuz I’m old and shaky. So if I am shaking, at least I’m shaking in unison. And then I will slowly bring it down. And I’m going to look and look and look on both sides until I bring it down. And once I’m happy with it, I will go ahead and press it on. And hope that Velcro just holds on for dear life.

NSP 45 Setup and Passes

Okay, so the next thing I’m going to do is I’m going to go ahead and I want to test something fairly unaggressive. This is—this is Z1—wrong product. This is our NSP 45. Okay, what that means is the diameter of the microsphere is 0.45 microns. A human hair—a human hair is about 90 microns. So, it’s half the diameter of a human hair.

Okay. Remember, since I’m first starting out, I’m going to go ahead and put three dime-size drops on here. And then after I break this pad in, I’ll switch over to pea-size drops. Just like that.

Five Solid Section Passes

Okay. And then for this, I will go ahead and make four to five solid section passes just to make sure I remove any micro-marring. Okay. Um, when you get your comfort level up, like I showed turning the speed down to spread your product out, but when you get really good at this, you just turn it on, spread your product out, and go. And that’s what I’m going to do here.

That’s spread out. Five lbs of pressure. Slow arm speed. With the polisher off, I just want to say that again. I’m going to put down five lbs of downward pressure on the head of the tool. I’m going to use a slow arm speed. I’m going to do a crosshatch pattern. I’m going to hit this about four or five times.

That was one. Three, four, five. There’s five solid textbook examples of what a section pass should look like. I counted them out loud so I didn’t get lost.

Avoid Skimming and Buffer Creep

And two things I just want to comment. Sometimes if you’re new to this and you turn this up to the high speed—this or any tool—and you hear that high speed, you’ll tend to want to match that sound with your arm speed and you’ll start doing this. Great. That’s called skimming. It’s not doing anything. So always be conscious of that. If you find yourself going faster to try to match your arm speed with the tool speed, uh, don’t do that.

And then the other thing is called buffer creep. Okay. Uh, even I do buffer creep. But what buffer creep is is you start out doing—I mean if you look at this, it’s pretty much like I said, it’s the size of a microfiber towel. And then of course I would do this one and then this one and then this one and this one. But buffer creep is when you start out with this nice little neat pattern, but every time you make a pass, you go a little further. In producing, you’re doing half the hood and none of the swirls are going to be gone because you just tackled too big of an area for this type of tool.

Pressure Taper for the Final Passes

So, avoid buffer creep and avoid, um, too fast of arm speed trying to match your arm speed to the sound of the tool. And then one more thing, and I have guys that dis—I have gurus, like famous personalities in the detailing world, that will 100% disagree with me, and that’s okay. As long as they get the shiny, I don’t care. But here’s what they’ll say. Keep the same amount of pressure all the way through the buffing cycle.

And here’s what I say. No, polishing paint is an art form. We bring the human elements of care and passion to what we’re doing. And for that last pass or two, I’m going to bring my pressure up. I’m not—this is not a grinding process. It’s a beautifying process. So for the last step, I could even turn my speed down to five. Little quicker arm speed, light pressure, couple of passes, and I can already tell you this paint’s going to look flawless.

Assessing the Finish and Real-World Detailing

Okay. Wow, that looks good. Brian’s going to like the new paint job on his car. Uh, I don’t know if it’ll help to show us real far. There’s nothing there to see, but let’s go ahead. And we’ll start back here where—what I call—the ugly. Am I into the ugly, Yansancy? Yeah. And I’ll move back and show the beautiful. Keep going. Keep going. Keep going. There you go. You’re good. That looks good.

So, to get this to where I’d want it to be, I’d be wanting to do at least two steps plus some way of ceramic coating it. And just to let you know, what—what if you had a car like this? I mean, this thing’s—can you come down here and capture when I talk about—look at the scarring on here over here. This isn’t smudges. This is scarring on the paint. Look at this scratch running this way. Here’s one running this way. Get the light. And there’s water spots everywhere. This paint is abused. That’s why it makes such a great demo vehicle. This is what I call real-world detailing.

Packages vs. Approaches

But let me just touch on the topic. What if—and what if you’re doing this for money and your customer didn’t want to pay for a two-step paint correction process? Because see, if you’re doing this for money, the—one of the first things you got to learn is me and Renny Doyle, we taught a class last year at Mobile Tech Expo—having a hard time, uh, thinking of what I— it was my class. He was my guest instructor with it. It did a great job, by the way. But we talked about if you’re starting out a detailing business, a lot of young guys, or not even young guys, because I got a lot of guys that are quitting their—retire—their career job, they take my class because they want to start a detailing business and they want to just nail it at the very beginning. They want to go through all the trial and error.

So—so not just young guys, but even older guys. When you’re first starting out, a lot of times in a business, you—you’ll just—you’ll do show car detailing to every car that’s brought to you, and you end up making a buck an hour. So, if you’re going to do this for business, you actually want to have at least three packages.

Three Tiers (or DIY Approaches)

You want to have a show car package for a car like that over there. Someone wants the best for their black Porsche. You want a mid-range package. That’s someone that wants it fixed up pretty good, but they don’t need that extra step of whatever the heavy paint correction step is to get a paint job perfect. Or you should have a budget package.

Now, a budget package is where you’re going to wash it and clay it. And then you’re going to use what’s called an AIO or an all-in-one. In the old days, we called it a cleaner wax. You can go find a product from Mothers or Meguiar’s called Mother’s Cleaner Wax. Okay. Uh, but I think when the phone was invented, people don’t want to type out cleaner/wax. So they just type out AIO. AIO. So it’s all-in-one. We have an amazing AIO. It’s called Z1.

Daily Drivers vs. Garage Queens

And here’s my point. If you—if this is your car, so there’s also—just let me touch on this. If you’re doing this for money, you have different packages. You have your entry level, your mid-range, your—your high-end or your show car package. If you’re doing this as an enthusiast, you know, uh, owner-detailed car, you—you don’t have packages, you charge for money, but substitute the word approach for the word package.

So, say you’re an average person, you got two or three cars, maybe your truck, which drives every day, sits outside, you just want to do one step. You’re taking care of the paint. It’s going to last longer with—you service the side of the car—but you don’t really want to do three steps to it. So, that’s a good place for a Z1. A big van, even like a Sprinter van, um, a large SUV.

But, if you got that thing that’s in the garage that’s kind of cool—or the wife’s car—maybe you want to do two or three steps. So, just always consider that—that if as a pro, you want to have different packages. As a do-it-yourselfer, you want to have different approaches. You’re not going to take—I’m not going to take every car I own and do a three-step multiple process paint correction step to it because they’re just daily drivers. Make sense? Okay. So, Z1.

Temperature Checks: Hand or IR

Okay. So, now that I’ve dialed in my test spot and we talked about inspection lights, um, we talked about how fast to move a polisher, how much pressure to put down, we marked the pad so you can tell if the pad is rotating or—oscillating or if it’s stalling out. And then we—we—we didn’t cover this. We want to talk about paint temperature.

So, um, I am sorry to say I forgot my, um, my thermometer. It’s an infrared thermometer. Get them down—it’ll get you down anywhere. Get one at Harbor Freight. And you just kind of point it at the paint. It’ll give you a temperature reading.

The Fight-or-Flight Hand Test

So—so a lot of times I don’t have it with me. Here’s what I use. Wherever I go, I take the human version. It’s right there. It’s my hand. Okay. So, after buffing a section, if I want to know if it’s too hot, I put my hand down on the surface and feel it. Um, and—and a couple things.

One. If I can put my hand down here and hold a conversation with you, it’s not too hot. If I put my hand down and instantly my knee-jerk reaction—it’s called the fight or flight reaction—I go—and I want to move my hand away quickly ‘cuz I might get burnt—that’s too hot. Quit buffing in that area. Let it cool down a little bit. Okay.

Uh, but anyway, that’s something—I mean most of us—most of us have a couple hands or at least one hand and, uh, it’s called the fight or flight—it’s called the—I have an article on this. It’s called the fight or flight method of gauging surface temperature.

So, either go down and spend 30 bucks and buy an infrared paint—uh—measuring tool or the heat measuring tool, temperature measuring tool, or just use your hand and use common sense. You know, if it’s getting too hot because maybe you’re trying to really work some scratches as you’re buffing and buffing and buffing, but you might want to just go, you know what, I think I’m going to go buff right here for a few seconds and let that cool down.

Pad Stalling: Setup Before Technique

Okay, so we covered, uh, correct technique, test spot. Now, let’s talk about pad rotation, pad stalling, pad oscillation. So, this Mustang has a fairly sharp concave curve here. And what I’m going to do is—in the last video, we talked a lot about pad stalling, but I didn’t really show how to overcome pad stalling. So, I’m going to do a deep dive on how to overcome pad stalling.

So, the first thing is—is look at your tool. At the beginning of this video, we talked about how this is just an entry-level tool. There’s nothing right with it. There’s nothing wrong with it. It’s 65 bucks brand new. It’s nothing I would ever use to buff out a car. Uh, but if I was just testing the waters and I wasn’t sure if I really wanted to become a detailer or detail my own cars, I might spend 65 bucks on this, you know, and see how I liked it. And if I did like it, then I could always get a better tool and give this to my son or give this to a friend.

Reinstall the Blue Pad for This Paint

Okay. So, what we’re going to do is I’m going to put the blue pad back on because that’s the one we—we dialed in for this paint, for this softness of paint. And this level of defects—and defects not only can be myriads—that means thousands, millions of swirls and scratches—but those defects could be deep or shallow.

So, if they’re really deep, it might be soft paint, but you still got to work at it because they’re so deep. You got to take a lot of paint off to level that surface. And it could be very hard with very shallow scratches that would clean up very easy. So, that’s why you really need to do that test spot.