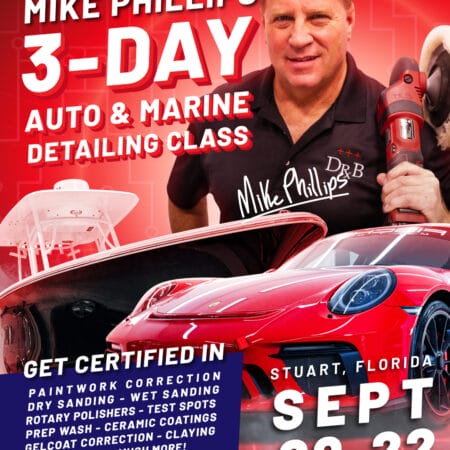

This course certifies students in the advanced exterior auto and marine detailing processes necessary to produce high quality results when detailing cars and boats professionally or as a hobby. The objective of this course is to restore real neglected automotive and marine paint finishes using different levels of aggression to produce results ranging from production to show car quality. Skill level: Beginner to Enthusiast/Professional

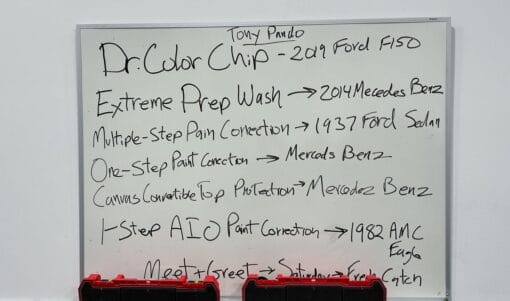

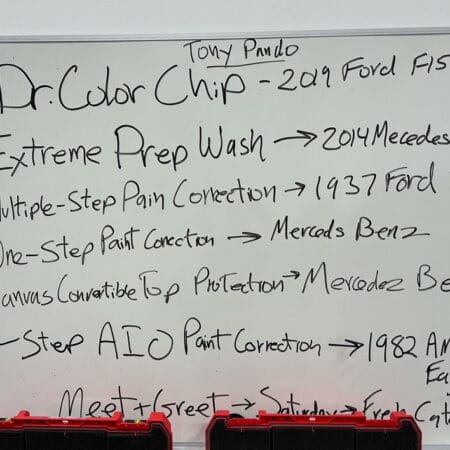

Day 1: Multi-Step & 1-Step Paintwork Correction

Prep Bay Procedures

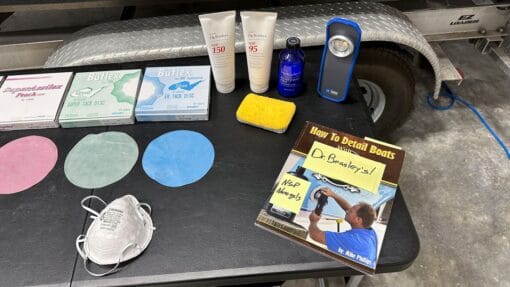

Students will begin the day learning how to properly prepare a real vehicle (not test hoods) for paintwork correction by washing, decontaminating and inspecting the paint. Students will then complete all necessary prep procedures on the vehicle to receive paintwork correction later in the day. Topics covered include:

- Extreme Prep Washing (2-Bucket & Waterless)

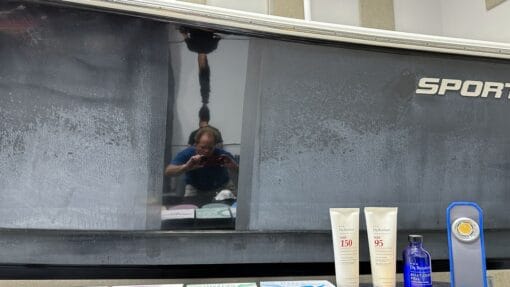

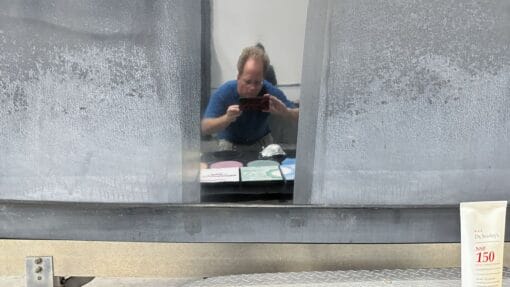

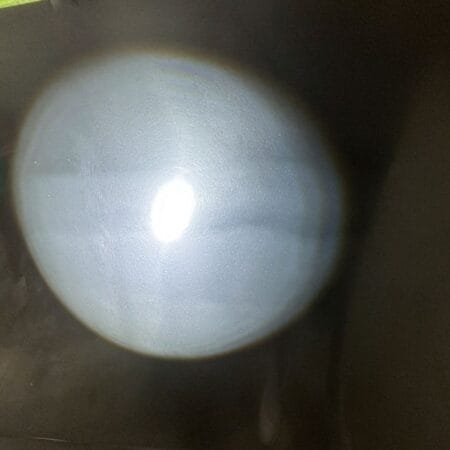

- Visual Paint Inspection using inspection lights

- Tactical Paint Inspection using baggie test

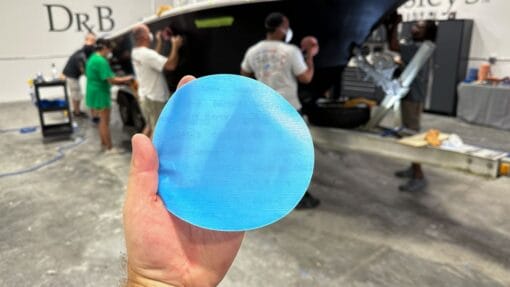

- Mechanical Decontamination with Clay Bars, Mitts & Towels

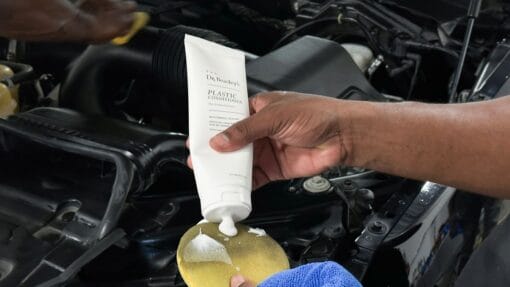

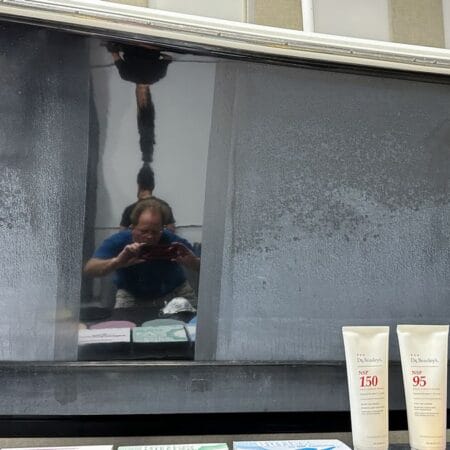

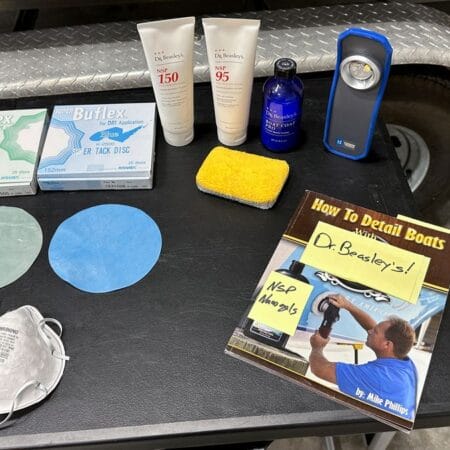

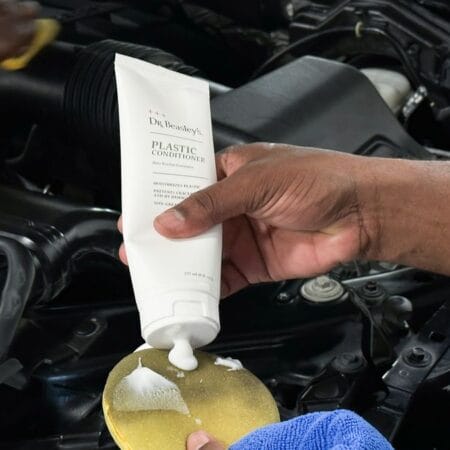

- Chemical Decontamination with Dr. Beasley’s Total Decon

- Paint Thickness Gauges

Multi-Step or Show Car Paintwork Correction

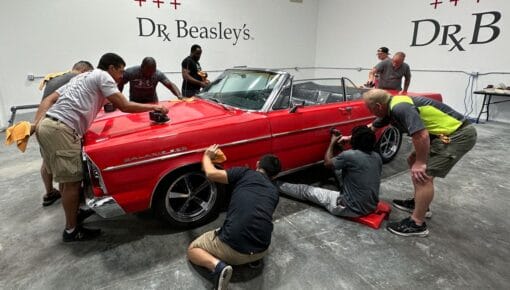

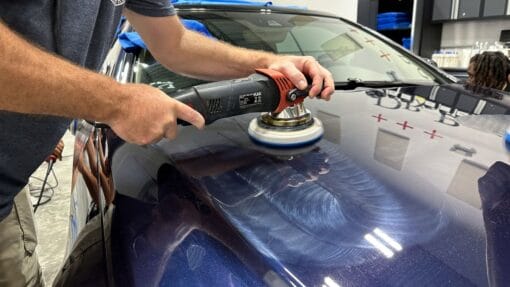

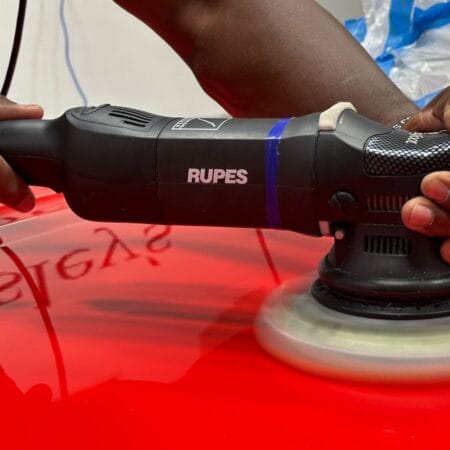

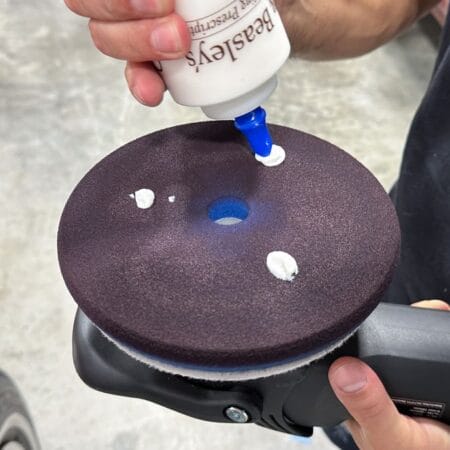

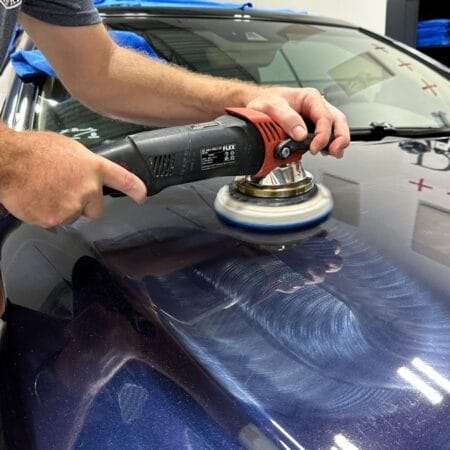

After prepping the vehicle, students will learn the proper processes necessary to complete a multi-step or show car paintwork correction. A multi-step paintwork correction is commonly done on vehicles that require heavy defect removal and don’t require fast results. Students will use Nano Surface Primers with rotary polishers and wool pads followed by orbital polishers with foam pads to complete a multi-step paintwork correction on the vehicle, restoring a show car finish. Topics covered include:

- Rotary & Orbital Polishers

- Wool & Foam Pads

- Test Spot Procedure

- Nano Surface Primers

- Section Passes

- Polisher Technique

Ceramic Coating Application

Following completion of the multi-step paintwork correction, students will apply a professional ceramic coating to protect the paint and enhance gloss.

One-Step or Production Paintwork Correction

For the afternoon session, students will learn the proper processes necessary to complete a one-step or production paintwork correction. A one-step paintwork correction is commonly done on vehicles that either require fast results or don’t require a great deal of defect removal. Students will use Nano Surface Primers with orbital polishers and foam pads to complete the one-step paint work correction.

Topical & Sub-Surface Glass Polishing

To end the first day, students will learn how to polish glass using the two vehicles from the previous paintwork correction classes. Students will start by using topical glass polishing to remove water spots and traffic film. If inspection reveals deeper defects like wiper scratches, sub-surface glass polishing will be used as well.

Day 2: Machine Dry Sanding and All-in-One Paintwork Correction

The second day of this course builds on the skills taught the day previous. Students will learn two paintwork correction techniques: aggressive machine dry sanding for orange peel removal (typically reserved for show car work) and All-in-One or AIO paintwork correction (typically used in production work). Students will use this knowledge to complete paintwork correction on real test vehicles.

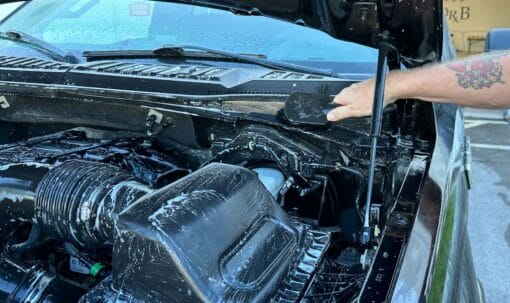

Extreme Prep Washing

Before an aggressive procedure like machine dry sanding can be attempted, the vehicle must be fastidiously clean. Students will learn a wider variety of procedures than on day 1, with topics covering:

- Headlight Correction

- Wet Wash Engine Detailing

- Canvas & Vinyl Top Cleaning

- Wheel & Tire Cleaning

- Foam Cannons & Guns

- One vs Two-Bucket Wash Methods

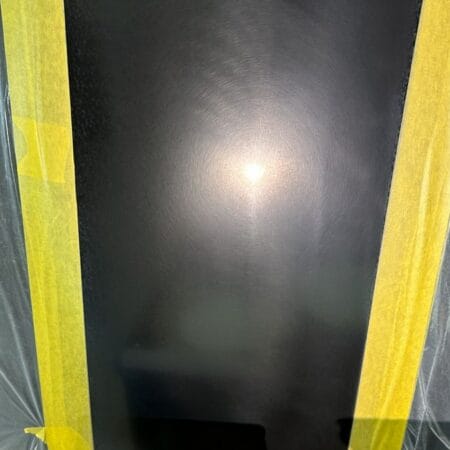

Machine Dry Sanding

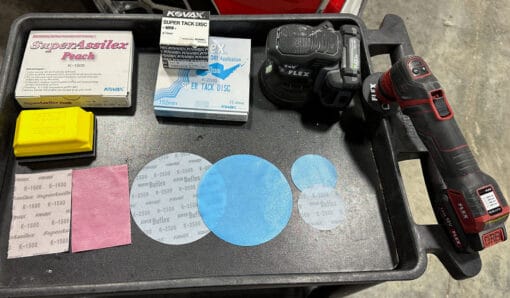

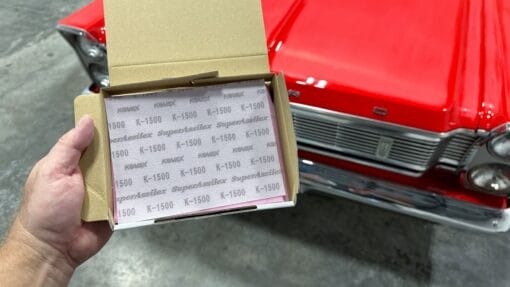

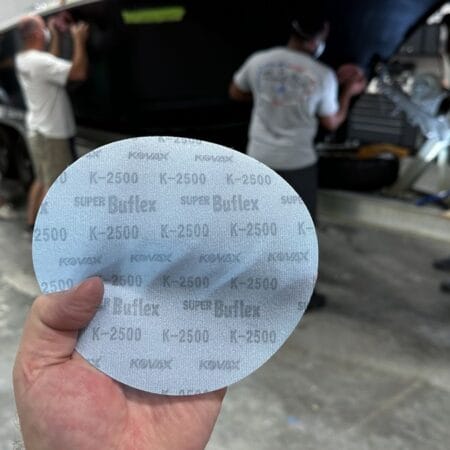

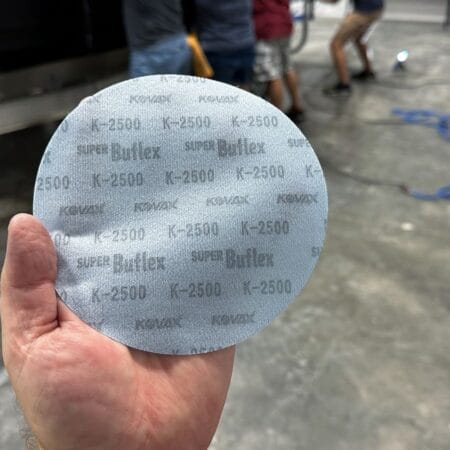

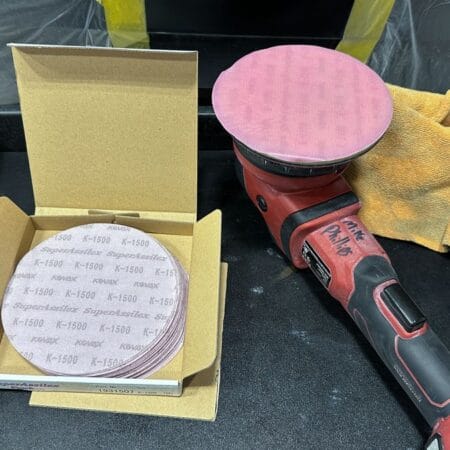

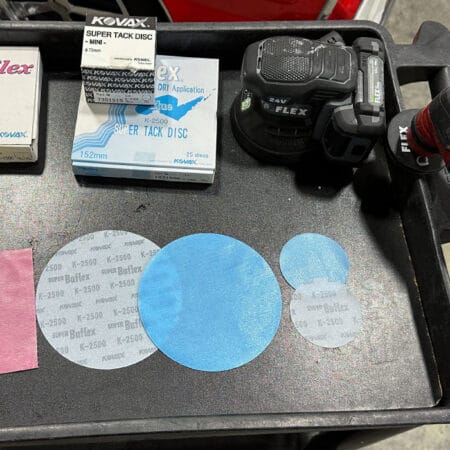

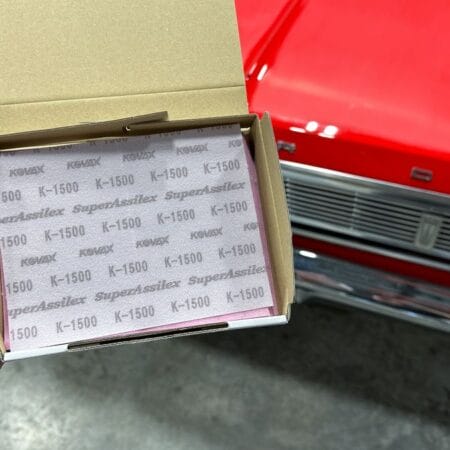

Once the vehicle is fully prepped, students will learn how to conduct one of the most aggressive paintwork correction procedures: machine dry sanding. The ultimate paintwork correction procedure for producing a show car finish, it is often used to remove orange peel on custom paint jobs for Concours d’Elegance events. After instruction, students will sand the vehicle’s paint, use rotary polishers to remove sanding marks and orbital polishers with foam pads to finish out before protection with a ceramic coating. Topics covered include:

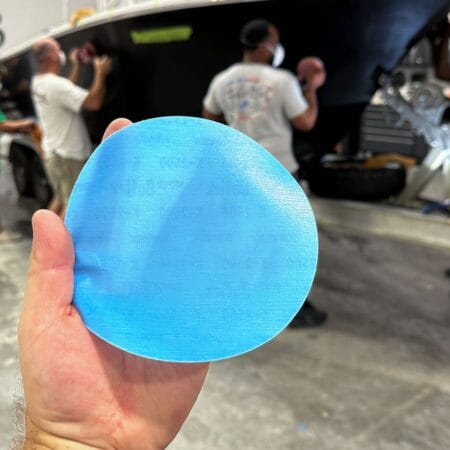

- Machine Dry Sanding with Orbital Sanders and Eagle Abrasives by KOVAX system

- Sanding Mark Removal with Rotary Polishers and Wool Pads

- Finishing with Orbital Polishers and Foam Pads

- Ceramic Coating Application

All-in-One Paintwork Correction

For the afternoon session, students will learn how to use an All-In-One paintwork correction procedure to restore and protect automotive paint at the same time. This is a common service for clients seeking the fastest results possible, or for those looking for a lower level of service. Students will use Dr. Beasley’s NSP Z1 and orbital polishers with foam pads to restore the vehicle’s finish.

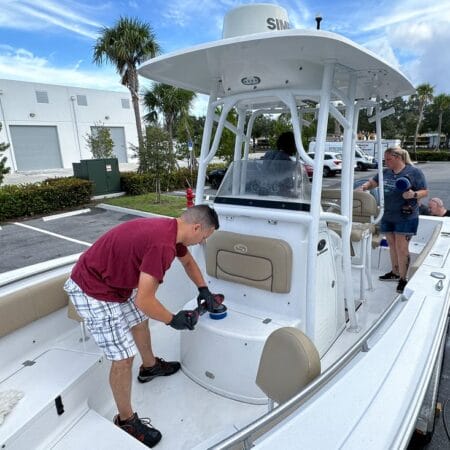

Day 3: Marine Detailing

The third day of this course teaches students how to restore and protect oxidized gelcoat on boats, yachts and other marine vessels to create a show car (er, boat) finish. This is an important skill for professional detailers operating in a coastal environment or any area near a large body of water — basically, anywhere there are boats to detail.

Machine Wet Sanding Gelcoat

Students will start with a pre-prepped boat to provide maximum time for gelcoat correction and ceramic coating protection. Using orbital sanders and the Eagle Abrasives by KOVAX system, students will machine wet sand the hull to remove deep oxidation.

Sanding Mark Removal from Gelcoat with Rotary Polishers & Wool Pads

Following the machine wet sanding step, the sanding marks instilled in the gelcoat must be removed as the next step towards a show boat finish. To do so, students will use rotary polishers with wool pads and a Dr. Beasley’s Nano Surface Primer.

Hologram Removal from Gelcoat with Orbital Polishers & Foam Pads

Once the sanding marks have been removed, the holograms instilled by the rotary polisher/wool pad combo must be polished out to leave a defect-free gel coat finish. Students will use orbital polishers with foam pads to complete this step.

Gelcoat Protection with Marine Ceramic Coating

Finally, the newly restored gelcoat must be protected with a durable marine ceramic coating — in this case Dr. Beasley’s Boat Coat Pro. Students will apply this coating to the entire hull, learning step-by-step how to properly install a marine ceramic coating.

Graduation Ceremony

Following completion of the boat, students will participate in a graduation ceremony with an opportunity for a photo with Mike as well as a group photo in front of the boat. Individual framed certificates will be mailed out from our headquarters in Chicago following the class.

Location

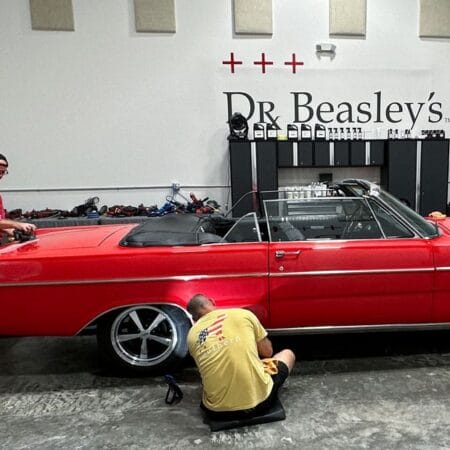

This training course will be held at the Dr. Beasley’s Operating Room in Stuart, Florida.

Dr. Beasley’s Operating Room

7934 SW Jack James Drive

Stuart, FL 34997

Lodging

Courtyard Stuart

7615 SW Lost River Road

Stuart, Florida 34997

772-781-3344

Amenities: In-house restaurant, Starbucks and full bar. The Cracker Barrel, McDonald’s and Chevron Gas Station/Mini Mart are right next door.

Holiday Inn Express – Stuart Florida

7900 SW Lost River Road

Stuart, FL 34997

772-287-2522

Amenities: Dunkin Donuts and La Forchetta – an Italian Restaurant are both right next door in the same parking lot. I highly recommend La Forchetta – superb, authentic Italian food. Wendy’s is also on the entrance road.

Dr. Beasley’s Operating Room

7934 SW Jack James Drive

Stuart, FL 34997

Instructors

Mike Phillips

Mike Phillips is a world-renowned detailing expert with over 30 years of teaching experience in the detailing industry. Now Chief Education Officer for Dr. Beasley’s, Mike is bringing his signature detailing classes to Dr. Beasley’s Future of Detailing education program to reach a whole new audience of detailing up-and-comers.

Items included with your ticket:

- One day of training for certification

- Framed certificate

- Dr. Beasley’s t-shirt

- $75 store credit