Last Updated April 29, 2022

Perfect smoothness is something of a “white whale” in the detailing industry. Enthusiasts and professionals alike will go to great lengths to achieve the most impossibly pristine paintwork possible. Oftentimes, though, detailers have felt underserved by the capabilities of dated polish technology in realizing this ideal.

These polishes and compounds of the past could remove defects, sure, but the paint was never level enough to truly get the “pop” people were looking for; hence the use of silicone oils and filling waxes. This was not great for ceramic coating application, as those oils and waxes prevented the coating from bonding. You could wipe them away with IPA and other solutions, but this was never foolproof and could result in wipe marring, not to mention wasted time.

Thankfully, advances in paint correction are changing all this, with Dr. Beasley’s Nano Surface Primers harnessing new “DxPrime” technology to achieve smoothness and gloss not seen in previous compounds and polishes. Paired with the NSPs’ priming abilities, it’s a game changer for ceramic coatings. So how is it done? Well, first you need to understand “the Science of Smooth” and how it affects the shine automotive paintwork produces. Let’s dig in.

The Relationship Between Smoothness and Gloss

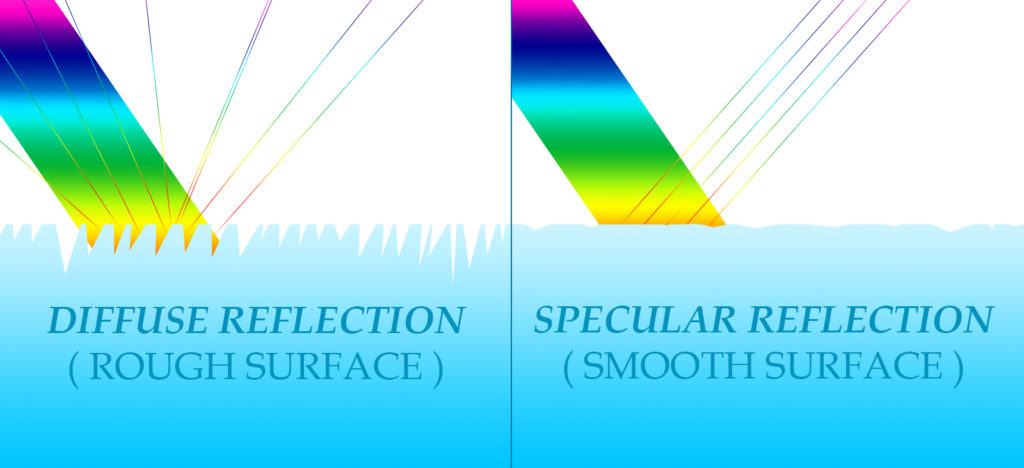

Surface texture is the number one determinant of gloss. That’s because gloss is based on the angle at which light is reflected from a given surface at the microscopic level. A bumpy, rough texture will produce something called a “diffuse reflection” (flat or satin appearance) while a smooth texture will produce a “specular reflection” (glossy or mirror appearance).

Think about it: light hitting a bumpy surface will scatter at a wide range of angles, depending on the shape of the microscopic hills, valleys and canyons in the surface. Only some of the light reflects directly into your eye; hence the dull effect. Light hitting a smooth surface, on the other hand, will reflect at a more controlled range of angles. With so much light concentrated at one angle, a clear reflection is visible within the surface, like a mirror.

Smooth surfaces concentrate light at one angle, creating a clear, specular reflection.

It’s for this reason that smoothness is the name of the game when it comes to paintwork correction. So what is it about the Nano Surface Primer system that gets paint so smooth? It all comes down to the DxPrime technology it uses; specifically the microsphere abrasives.

How Microsphere Abrasives Cut & Smooth

To get the smoothest (and therefore shiniest) paint possible, you need to use abrasives with a precise and controlled rate of cut. If the amount of clear coat you’re removing is varying too much, you’ll end up with a rougher finish that doesn’t quite “pop”.

Older abrasive technologies like DAT (Diminishing abrasive technology) and SMAT (Super micro abrasive technology) were frequently guilty of this. Inconsistencies in abrasive size and shape would cause some abrasive particles to remove more than others. Uneven distribution within the polish or compound base would cause abrasives to bunch up in one area, again causing the amount of clear coat removed to vary.

All of these factors would lead to a surface with less scratches but a rough texture. That’s why these old polishes had to use silicone oils and waxes to fill in the rough texture and get the level finish desired. But then if you were putting a coating on, you had to remove those oils and waxes first, and even then you couldn’t be 100% sure you got it all off. Then there was also a chance you rubbed some minor scratches into the surface as you wiped away the oils. You’d be back to square one, correcting scratches yet again. It was all horribly inefficient, and it all stemmed from lackluster abrasives.

Microsphere abrasives eliminate these variances, resulting in an even cut rate that produces a much smoother and much glossier finish, primed and ready for coating. Here’s how they do it:

- Microsphere abrasives have a tightly controlled size. Compared to the multiple microns of variance with DAT & SMAT, microspheres are controlled down to .5 of a micron.

- Microsphere abrasives are uniformly spherical. Each abrasive has the same number of cutting facets, meaning they each have the same cutting potential.

- Nanogel distributes the microsphere abrasives evenly. Ok, so this is more about the nanogel than the microspheres, but it’s still an important factor. The nanogel’s thick nature means microspheres are held in place within the substance, ensuring no abrasive clumping occurs.

How “The Science of Smooth” Works In Practice With Nano Surface Primers

Let’s get specific on how the primers in the NSP system actually work together in achieving a smooth finish. The two cutting primers, NSP 150 and NSP 95, essentially remove major defects and add film build to the corrected surface, replacing the clear coat material lost in correction. The film build here is smooth but not quite there; to get the level surface you’re expecting you need to follow-up with NSP 45, the finishing primer. It is here that the built-up protection over the smoothed paint is finished into a level, glossy surface with added anchor points to ensure a durable coating bond.

Questions? Comments?

Email Us