No Chairs. 100% Hands-On.

We’re proud to announce that detailing legend Mike Phillips will be leading and crafting the curriculum for the Future of Detailing Advanced Paint Correction Clinic! Mike has adapted the rigorous paint correction lessons he’s developed over the years for the Future of Detailing format, resulting in a comprehensive course that covers everything from multi-step paint correction to machine sanding. Check out Mike’s syllabus below:

Day 1 | Topics Covered

Morning Session | Multiple-Step Paint Correction (AKA Show Car Detailing)

In the FoD Advanced Paint Correction Clinic, students will learn how to take a neglected car’s finish to its maximum potential! This includes:

How to Do a Proper PREP Waterless Wash

Just like there are two types of normal wash styles, there are two types of styles for doing a waterless wash: waterless prep wash and waterless maintenance wash. In this class you’ll learn how to do both styles.

Visual Paint Inspection – Topics Covered

- How to identify various paint defects and determine if they can be safely fixed or not.

- The importance of inspecting a vehicle for previous damage.

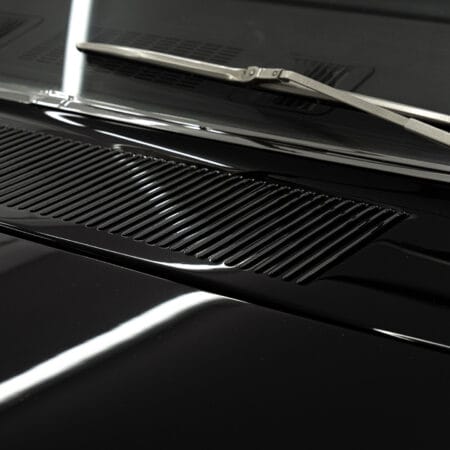

- How to inspect windshields for sub-surface defects like wiper marks, swirls and scratches.

- How to inspect for clear coat failure or other unfix-able paint issues.

- How to inspect for defective parts or components including side mirrors, antennas, mud flaps, etc. to document and notify the owner about.

- Surfaces and/or sections to tape-off or cover and protect.

Tactical Paint Inspection (Baggie Test)

Students will learn how to correctly inspect for contamination using the Baggie Test, as well as the correct way to show customers the level of paint contamination on their vehicle.

Mechanical Decontamination (Claying)

Unless a car is brand spanking new, most car are going to have some level of bonded contamination on the exterior surfaces. This session covers how to remove the contamination and why you simply cannot count on machine polishing to remove contaminants.

Paint Thickness Gauges

Students will learn how to use a PTG to determine the thickness or thinness of the paint and how to safely proceed to the next steps.

Tape-Off and Cover-Up

Students will learn which types of materials or areas should be covered and protected from machine buffing and product splatter.

How to Do a Test Spot

The single most important thing you should do before any paint correction on anything is a proper Test Spot. The importance and value of doing a proper Test Spot is explained in detail. How and where to perform a Test Spot is taught in detail as well as how to inspect the results. How to dial-in the paint correction process is taught based upon results from Test Spot.

How to Correctly Use a Swirl Finder Light

Quality inspection lights are necessary throughout the detail process. How to use different inspection lights, including “Swirl Finders”, is demonstrated and explained in detail.

How To Use A Panel Wipe To Inspect For Accurate And True Paint Correction

Polishing oils, fillers, waxes and other ingredients can give a false appearance causing you to think the defects are removed. We show how to use a panel wipe to obtain true and accurate results.

Paint Correction

How to Correctly Use a Rotary Polisher

This is the most powerful tool when it comes to doing paint correction. Correctly used, it’s like a scalpel in the hands of a world-renowned surgeon. Improperly used and you can get into trouble real fast. In this first session covering the rotary polisher, you’ll learn foundational skills that you’ll build on over the course of the rest of the day as well as for the dry sanding class.

How To Use An Orbital Polisher

Orbital polishers are safe for beginners and effective. You’ll learn all the correct techniques to maximize your time while consistently achieving pro quality results.

Installing a Ceramic Coating

How To Use A Panel Wipe

A panel wipe is a solvent used to prep paint for installing a ceramic coating. In this class session, you’ll learn a 2-step approach to ensure the surface is surgically clean for maximum bonding, longevity and performance for any coating you install.

How to Install a Ceramic Coating

Coatings are truly the best way to protect your paint when it comes to protection, longevity and atomic gloss! In this class session, you’ll learn how to correctly install ceramic coatings and how to avoid the hassles of high spots.

Finishing touches

- Cleaning interior glass.

- Using glass coating.

- Restoring and protecting exterior plastic trim.

- Polishing metal surfaces.

- When and how to use tire dressings and/or tire coatings.

- Coating and protecting wheels.

- Detailing door, hood, trunk and hatchback jambs.

- Cleaning and conditioning rubber door and hatchback gaskets.

Afternoon Session | 1-Step Paint Correction & Ceramic Coatings

Topics covered:

- How to do a proper prep waterless wash.

- Visual paint inspection.

- Tactical paint inspection.

- Mechanical decontamination.

- How to set your own or your customer’s expectations for a one-step paint correction.

- How to use and master orbital polishers to reduce time and maximize paint correction results.

- Topical glass polishing.

- Panel Prep.

- Installing a ceramic coating.

- Finishing touches.

Day 2 | Topics Covered

Machine Sanding for a True Show Car Finish

Day 2 puts the “Advanced” in “Advanced Paint Correction Clinic” by covering machine sanding, a high-level skill that produces professional show car results. Topics covered include:

How To Machine Sand Custom Paint To Remove Orange Peel

How To Create A True Show Car Finish On Custom Paint Jobs

The highest skill and knowledge base most detailers strive to possess is how to carefully sand flat a custom paint job to remove orange peel and create a true show car finish with maximum D.O.I. (Distinction of Image).

Sanding Paint

99.9% of the people on Earth should never sand paint. But for the 1% that have the desire to learn how to do it and do it right, this is the class for you. The ability and know-how to sand paint sets you apart from the rest of all the me-too detailers. Just being able to talk intelligently about it after gaining firsthand, real-world experience is worth the price of the class.

Overview

This class covers four different sanding techniques to level orange peel and other surface textures for creating a true show car finish with 100% D.O.I. as the goal.

D.O.I. = Distinction of Image

The goal when creating a true show car finish is to level the paint as flat as possible using sanding techniques and then after sanding, removing the sanding marks to restore a clear, high gloss shine.

Techniques Covered:

- How to machine sand paint flat using 6” and 3” sanders.

- The proper use of rotary polishers, wool cutting pads to remove 100% of the sanding marks.

- How to use orbital polishers with foam pads to finish out hologram and swirl free finish.

- How to seal the paint using either a wax, paint sealant or ceramic coating.

Rotary Polishers

After sanding the paint flat, students will draw from the foundational skills learned on Day 1, like how to use a rotary polisher with a compound and a wool pad to remove 100% of the sanding marks without making mistakes.

Orbital Polishers

After removing all the sanding marks, next you’ll remove any holograms in the paint and then maximize gloss and clarity in preparation to seal the paint with a wax, paint sealant or ceramic coating.

Real Cars – No Demo Hoods

Anyone can sand a section about the size of a microfiber towel on a flat panel that’s about waist high. This is what you see in pictures for all the other classes advertised. At this class, you’ll learn how to tackle a real car. Learning on an actual car is what’s really valuable and has IMPACT!

Certification Award Ceremony

After the cars are sanded and polished to perfection, you’re going to be tired. You are among the elite in the world that have now made it through to the end of the most hands-on detailing classes on planet Earth!

Location

Lake Country Manufacturing, Inc.

950 Blue Ribbon Circle North, Oconomowoc, WI 53066 USA

Price

$1400

Ticket Includes

- Dr. Beasley’s T-Shirt

- Breakfast & Lunch – Thursday & Friday

- Framed Certificate

- $200 Dr. Beasley’s Store Credit

- Gift Bag ($300+ Value)

- NSP 45, 95, 150 & Z1 (8 oz ea)

- NSP GL (8 oz)

- Exclusive FoD-branded HDO pads from Lake Country MFG

- Griot’s Garage swag

Lodging

Hilton Garden Inn Oconomowoc (Click to Book)

1443 Pabst Farms Cir, Oconomowoc, WI 53066

(262) 200-2222

Featured Trainers:

Mike Phillips – Chief Education Officer for Dr. Beasley’s – IDA CD-SV, MC, RIT

Chris Racana – Director of Success for Dr. Beasley’s – IDA CD-SV, RIT

Rod Kraft – Griot’s Garage – Sales Manager

Chris Metcalf – Key Account Manager – Flex Tools North America

Andy B. Cool – Lake Country Pro Team – IDA CD-SV

Scott Voelz – Product Manager – Lake Country Manufacturing

Jim Lafeber – President, Research & Development, Dr. Beasley’s – IDA CD-SV, RIT

Bob Eichelberg – Global Sales Director – LC Power Tools

Bob Myers – Regional Manager – Central Region – Lake Country Manufacturing – IDA CD-SV, MC, RIT

Zach Smith – Authorized Trainer – Dr. Beasley’s – Owner of Pittsburgh Pro Car Care – IDA CD-SV

Lance Beckett – Authorized Trainer – Dr. Beasley’s – Lead Detailer Mirror Image TN