CHALLENGE OF GLASS POLISHING

CHANGING THE WAY WE CORRECT GLASS

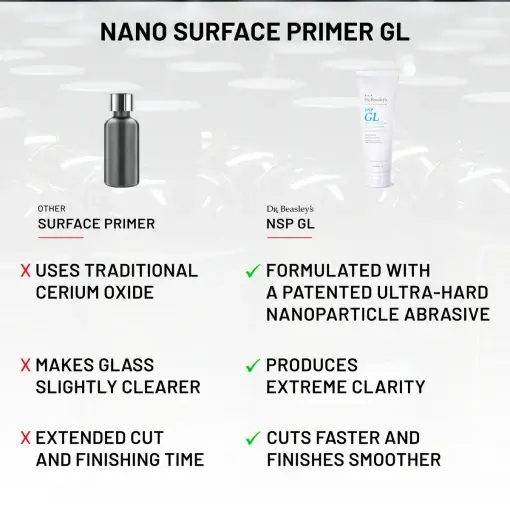

The biggest problem with glass polishing is that it can take a long time, especially when you need to get rid of scratches, etching and other subsurface defects. Recognizing this, Dr. Beasley’s founder and lead chemist Jim Lafeber got in the lab and re-engineered his Nano Surface Primer paint correction technology for glass — thus, NSP GL was born. At first Jim tried cerium oxide, a conventional glass polish abrasive, but he wasn’t getting results fast enough. That’s when Jim realized he needed to think outside conventional abrasives and start looking at other industries like the military.

INNOVATIVE ABRASIVE TECHNOLOGY

PATENTED NANOPARTICLE ABRASIVES FOR A FASTER, MORE EFFICIENT CUT

After rigorously testing multiple abrasive types, Jim sourced a unique, ultra-hard nanoparticle abrasive with diverse applications. This patented technology is used by the Air Force to polish F-35 fighter jet canopies for crystal clear in-flight visibility. Through careful engineering, Jim adapted the technology for automotive glass. Testing the technologies side-by-side, he found the patented nanoparticle abrasive to be superior to cerium oxide in speed, efficiency and clarity.

MECHANICAL & CHEMICAL ACTION

A CHEMICAL/MECHANICAL ACTION ACTIVATED BY NANOGEL

What makes the nanoparticle abrasive so effective is the way it works with the proprietary NSP nanogel. The nanogel carrier does a number of things — it distributes abrasives evenly for an efficient cut, it keeps the glass cool to avoid burning — but most importantly, it causes mechanical and chemical reactions that activate the abrasives. In additional to all that, the nanogel is also establishing a primed ceramic foundation for the nanocoating to follow, eliminating the panel wipe step like all our Nano Surface Primers do.